Gas introduction method for reinforced gas-liquid mass transfer and device

A technology of gas introduction and gas enhancement, which is applied in the field of gas-liquid mixing and mass transfer, can solve the problems of increasing the specific surface area of gas-liquid contact, improving the effect of gas-liquid mass transfer, and affecting the gas utilization rate, etc., to achieve enhanced mutual permeability , Easy to install, reduce the effect of cleaning investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

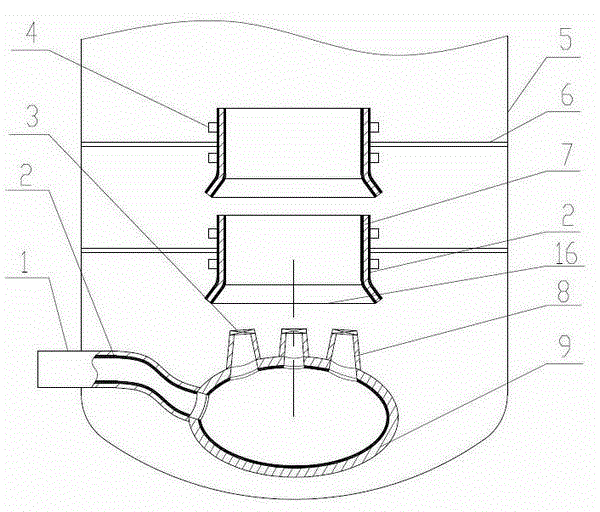

[0032] Embodiment 1: attached figure 1 It is a structural diagram of the built-in gas introduction device of the present invention, which is installed below the liquid level in the gas-liquid reactor 5, and six gas nozzles 8 correspond to a group of coaxially arranged two-stage circulation mixing cylinders arranged behind the gas nozzles 8 Example at 7 o'clock.

[0033] Present embodiment 1 comprises the inlet pipe 1 that stretches into below the liquid level in the gas-liquid reactor 5 and the air distribution bag 9 that is installed at the end of the air inlet pipe 1, and the inner wall of the air inlet pipe 1 and the air distribution bag 9 is coated with tourmaline or other An anion coating 2 refined from rare earth stone materials is connected to 6 gas nozzles 8 integrated with a fluid ultrasonic whistle 3 on the gas distribution bag 9. The structure of the gas nozzle 8 is as follows: figure 1 As shown, its main body is a tubular with a circular cross-section and a taper,...

Embodiment 2

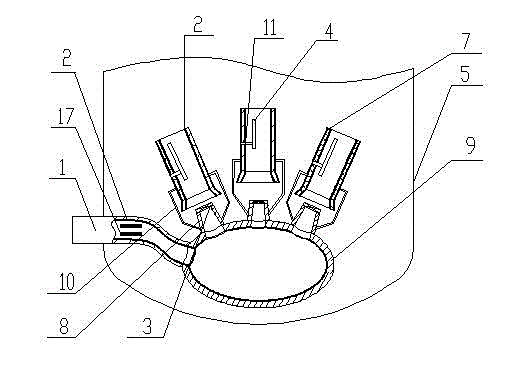

[0034] Embodiment 2: attached figure 2 It is another built-in gas introduction device of the present invention, which is installed below the liquid level in the gas-liquid reactor 5, and is an embodiment in which each gas nozzle 8 corresponds to a single-stage circulating mixing cylinder 7 arranged thereafter.

[0035]Its structure comprises the inlet pipe 1 that stretches into the gas-liquid reactor 5 below the liquid level and the gas distribution bag 9 installed at the end of the inlet pipe 1, and the multi-layer plate-shaped packing 17 is set in the air inlet pipe 1, and the packing 17 includes several The gas flows to the parallel packing plates. The outer surface of each layer of packing plates is coated with negative ion coating refined from tourmaline or other rare earth stones. There is a certain distance between each layer of packing plates as gas channels, and other packing plates can also be used. shape filler. Six gas nozzles 8 integrated with the fluid ultrason...

Embodiment 3

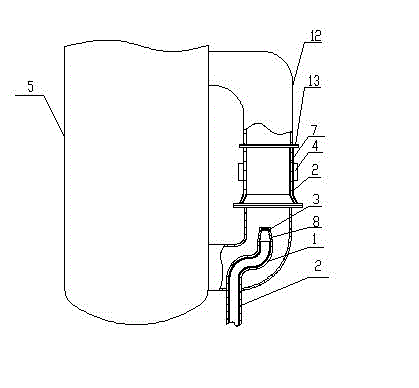

[0036] Embodiment 3: Attach image 3 It is an external gas introduction device of the present invention, installed on the external circulation pipeline 12 outside the gas-liquid reactor 5, and is an embodiment in which one gas nozzle 8 corresponds to one single-stage circulation mixing cylinder 7 arranged behind it.

[0037] Its structure includes the air inlet pipe 1 arranged outside the gas-liquid reactor 5 and extending into the bottom of the external circulation pipe 12 arranged outside the gas-liquid reactor 5, and the inner wall of the air inlet pipe 1 is coated with tourmaline or other rare earth stone refined The negative ion coating 2 that forms, connects the gas nozzle 8 of an integrated fluid ultrasonic whistle 3 at the air intake pipe 1 end, and the structure of the gas nozzle 8 and the fluid ultrasonic whistle 3 is identical with that in the above-mentioned embodiment 1. The circulation mixing cylinder 7 integrated with the ultrasonic transducer 4 has a single-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com