Trans-scale design method of high-speed milling cutter and milling cutter

A design method and high-speed milling technology, applied in milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problem that the microstructure and macrostructure evolution behavior of tool materials cannot be quantitatively described, and the design and development of new high-speed milling cutters lack scientific basis. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A cross-scale design method for high-speed milling cutters, the method includes the following steps:

[0025] 1. The safety and stability design model of high-speed milling cutter is established.

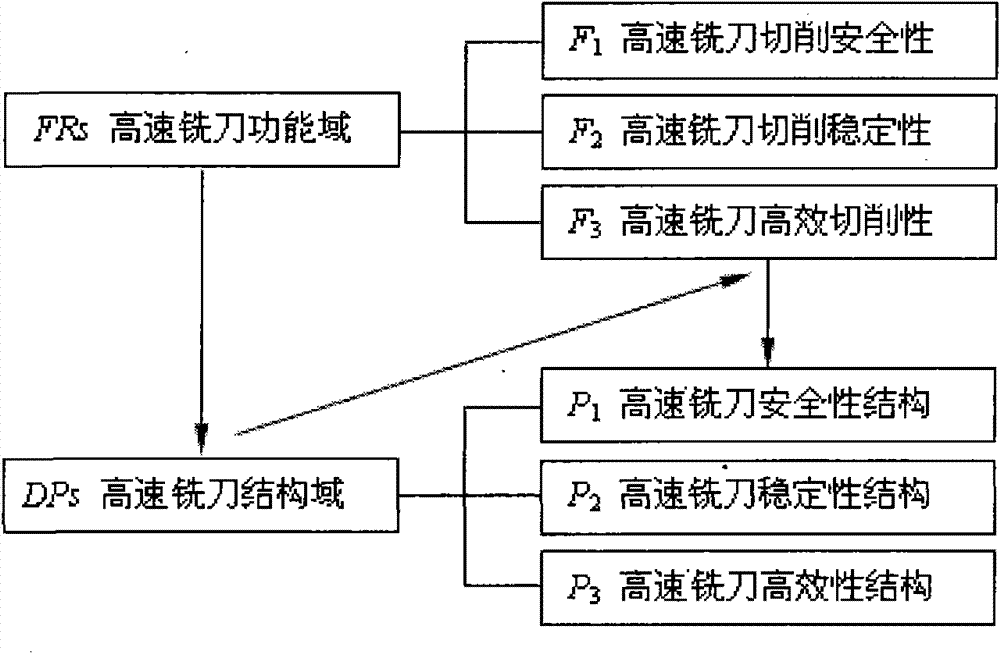

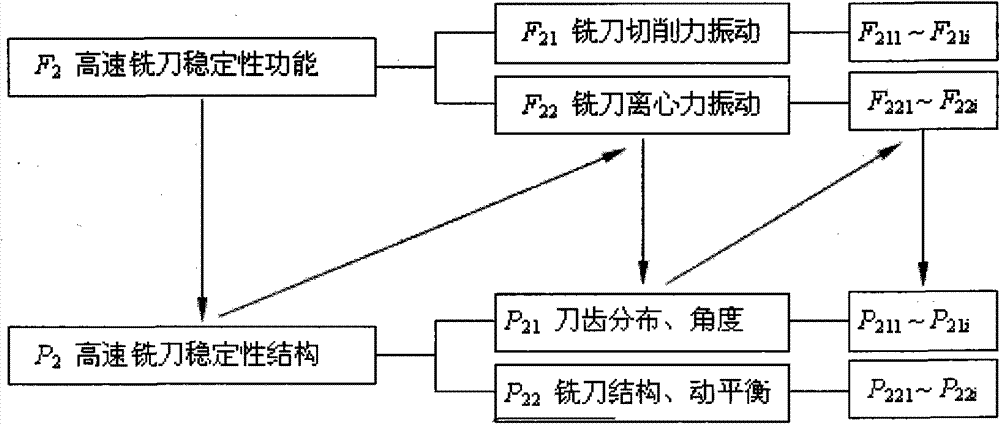

[0026] According to the general theory in the field of design - axiomatic design point of view, from the perspective of satisfying the safety, cutting stability and cutting efficiency of high-speed milling cutters, the "interaction" between functional domains (FRs) and structural domains (DPs) of high-speed milling cutters is carried out. font" mapping transformation, decomposing its high-speed cutting function, such as figure 1 shown.

[0027] From this, the functional decomposition scheme of high-speed milling cutter can be obtained as follows:

[0028]

[0029] In the formula: A 11 ~A 33 are the two-level design matrices for high-speed milling cutter-related functions.

[0030] The initial design matrix for constructing a high-speed milling cutter is shown in Table...

Embodiment 2

[0058] A safe high-speed milling cutter, which consists of: a tool handle and its connected cutter head, through the milling cutter rake angle, entering angle, angle between cutter teeth, number of milling cutter teeth, milling cutter diameter, stiffness matrix , mass matrix and dynamic balance precision parameters series high-speed milling cutter macro / meso structure parameters and material selection, carry out "zigzag" mapping transformation between meso structure domain, macro structure domain and functional domain, design matrix transformation and functional coupling Quantitative evaluation, and through the high-speed milling cutter safety macro / mesoscopic safety model and associated design matrix, the milling cutter obtained by optimizing the parameters in a way of visually expressing the synchronous associated evolution process of its macroscopic / mesoscopic structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com