Regular L-shaped sliding plate applying linear motor driving

A technology of linear motors and skateboards, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of low strength, difficult installation, and heavy load of skateboards, so as to reduce energy consumption, increase life, and stress small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

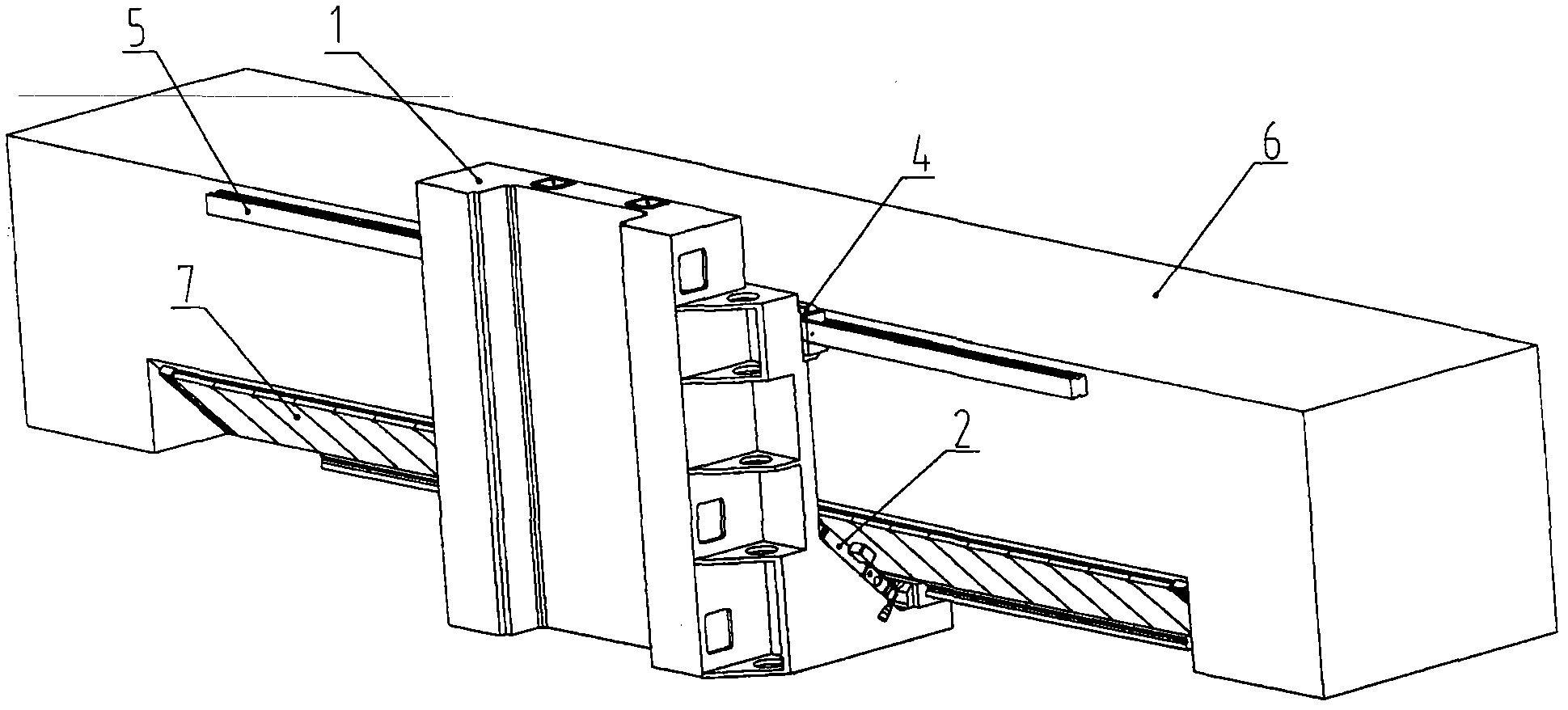

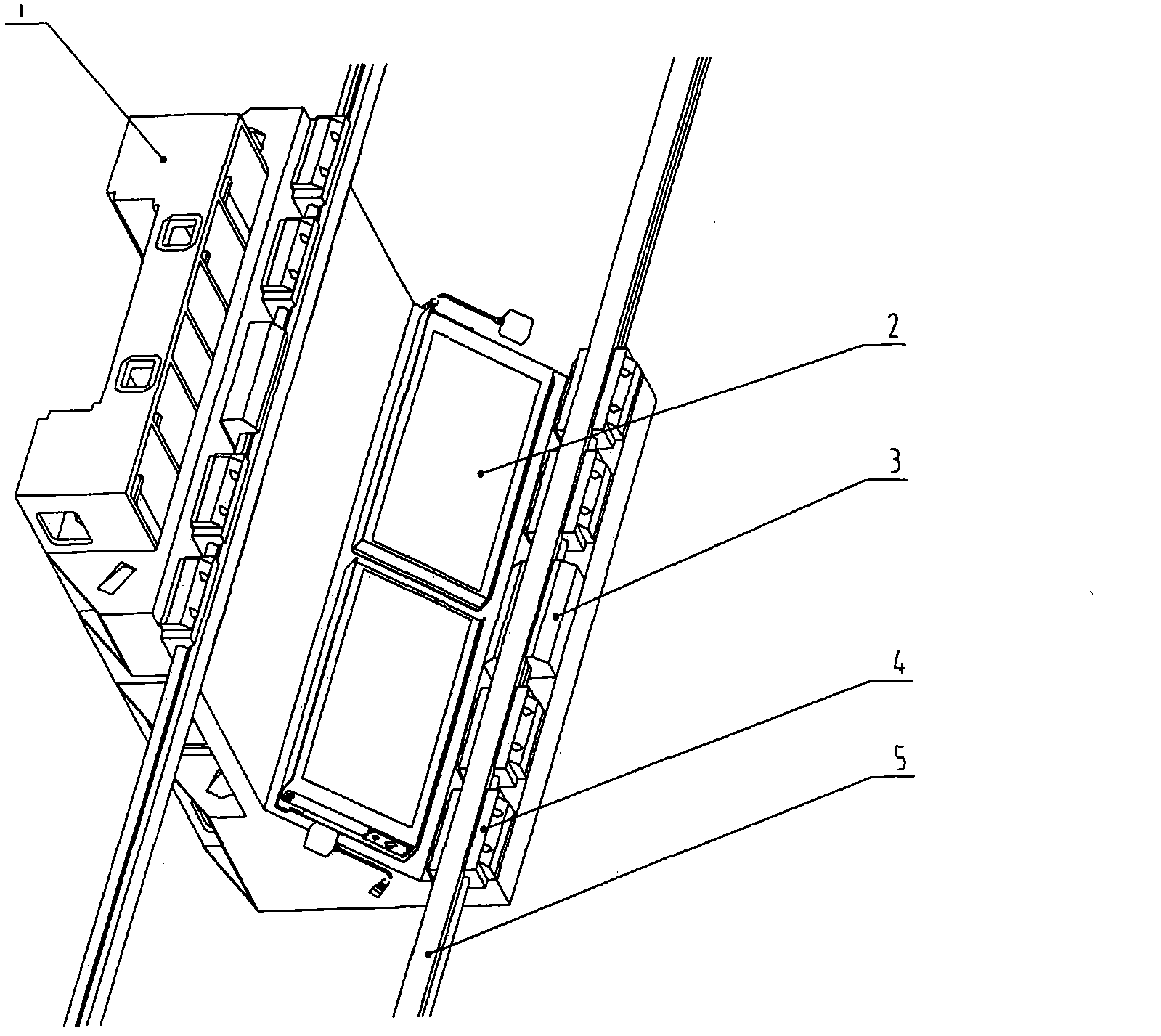

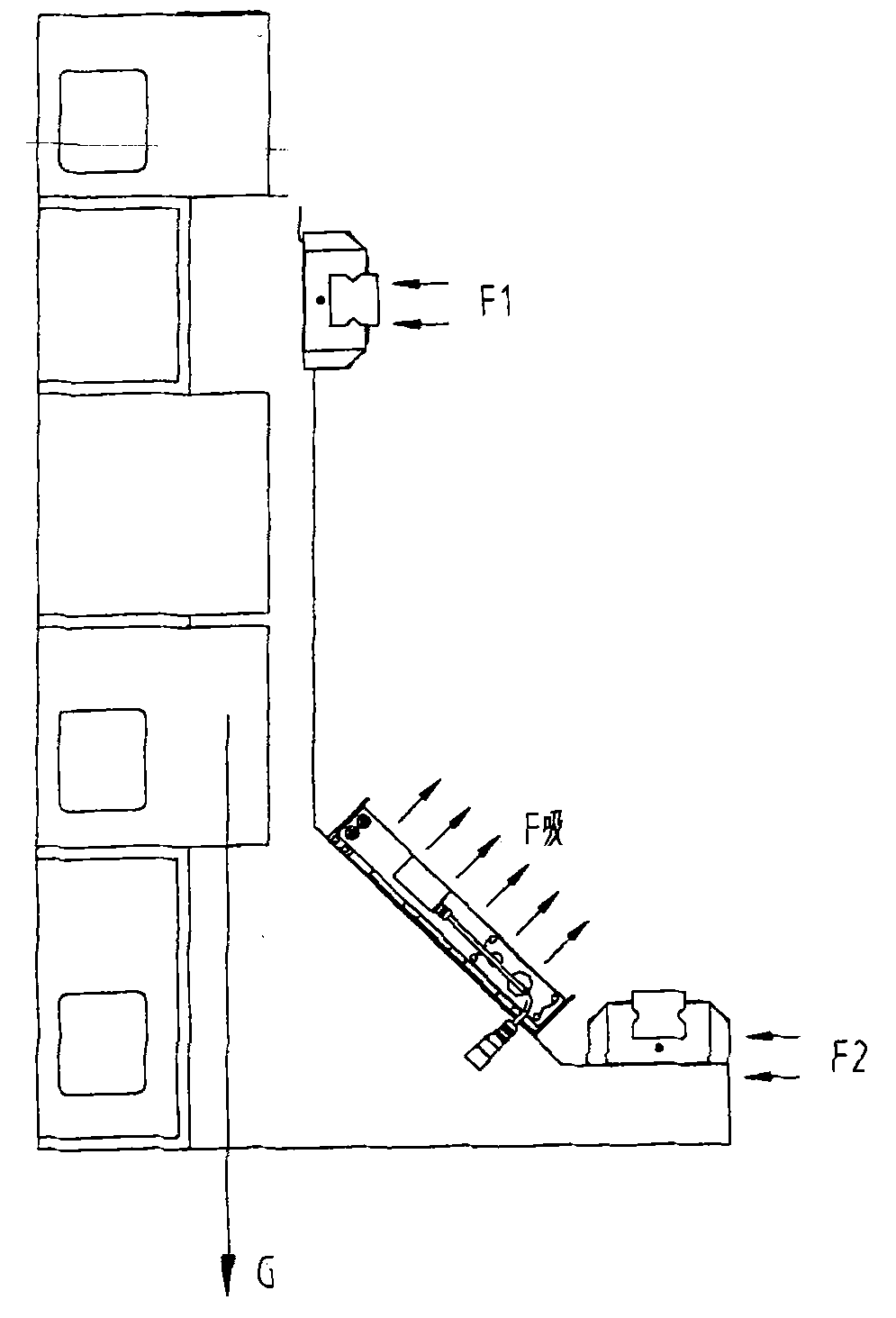

[0016] A positive L-shaped slide plate driven by a linear motor is used to support the horizontal movement of the beam 6, see figure 1 , figure 2 , it is characterized in that the upright column of the skateboard and the bottom corner of the front are in a positive L shape, and the L corner is a slope reinforcement structure, and the front elevation of the L-shaped skateboard and the upper plane of the right-angle bottom edge are respectively equipped with sliders 4, which are combined with guide rails 5 installed on the crossbeam. Hanging installation, the hydraulic brake 3 is installed side by side in the middle of the slider 4; the linear motor primary 2 is obliquely installed on the corner slope structure of the slide plate 1, and the linear motor secondary 7 is installed on the left side of the lower slope of the beam.

[0017] The guide rail 5 is fixed on the front facade of the crossbeam 6 and the bottom edge of the same-side bottom inner slope. The slide plate 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com