Punch press with multiple protection mechanisms

A protection mechanism, punching technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of not meeting the safety requirements of punching machines, affecting the operation process and productivity, safety device work-related accidents, etc., to achieve ingenious design, high production efficiency, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

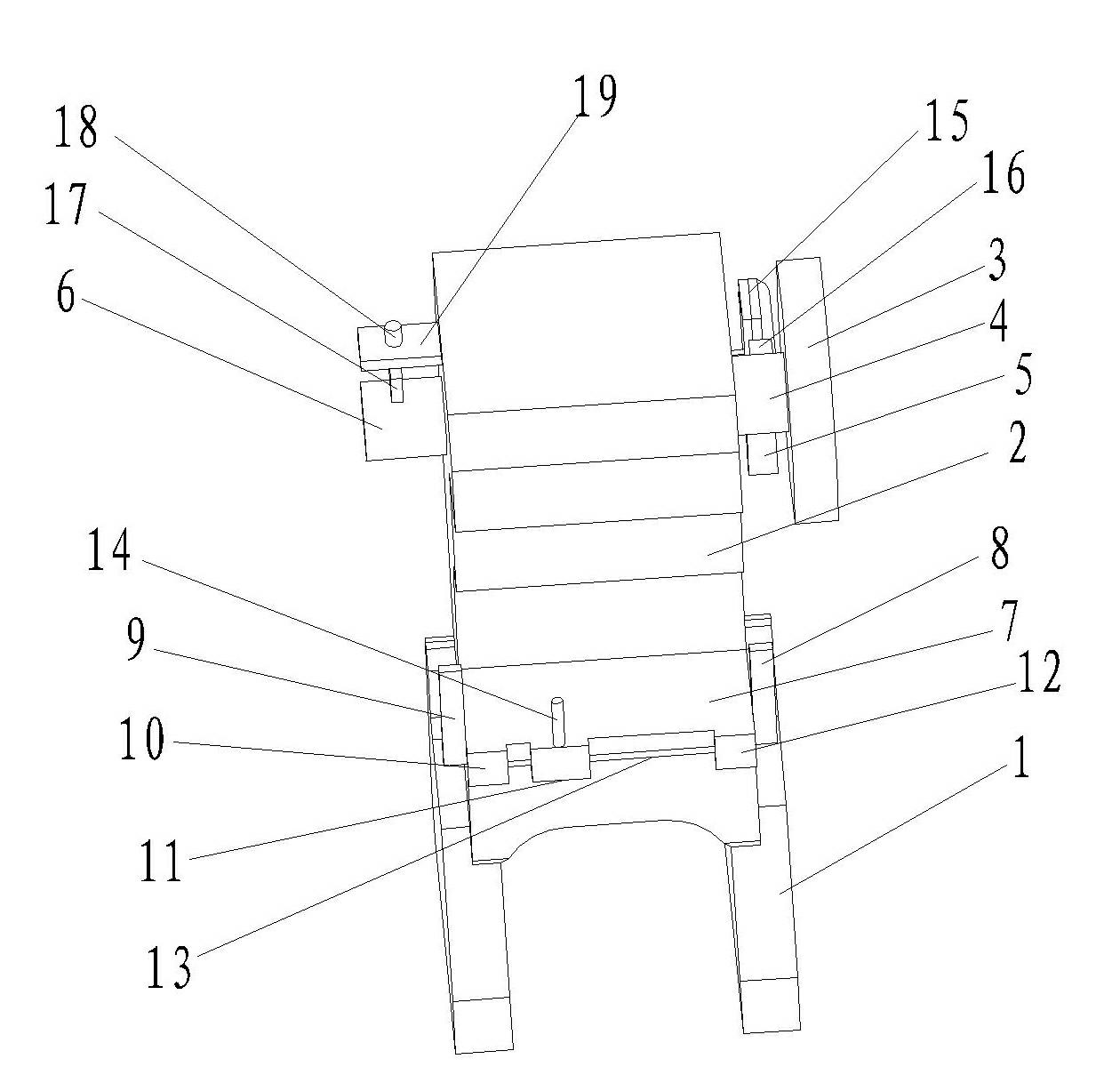

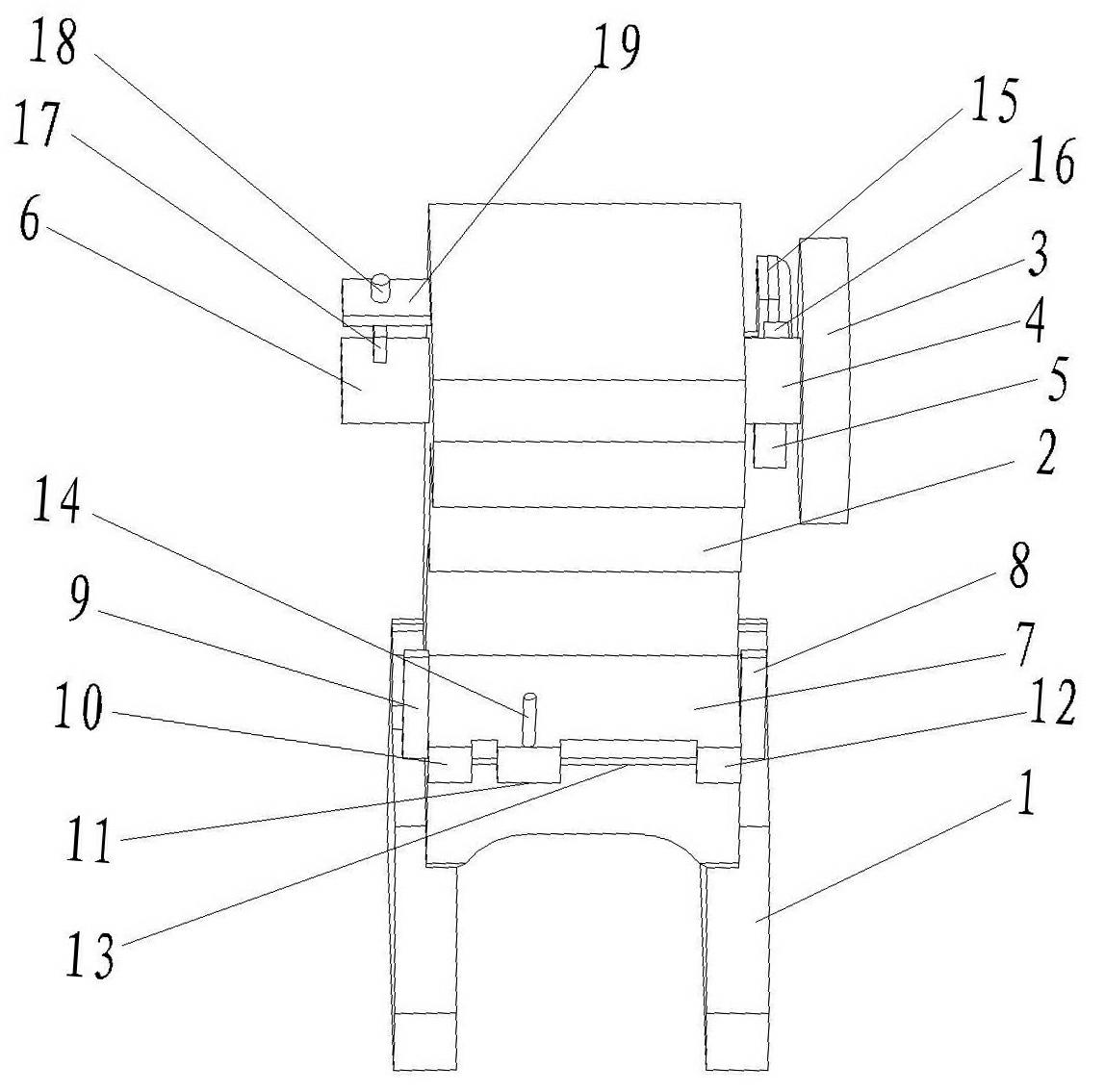

[0010] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0011] see figure 1 , the present invention has a punching machine with multiple protective mechanisms, including a machine 1, a die 2, a flywheel 3, a transmission shaft 4, a clutch 5 and a crankshaft 6, and the two ends of the worktable 7 of the machine 1 near the outside are respectively Infrared modules 8 and 9 are installed, and three magnetic couple cylinders 10, 11, 12 are fixed side by side on the outside of the workbench 7. A connecting rod 13 passes through the three magnetic couple cylinders, and the middle magnetic couple cylinder 11 is vertically fixed. A beater bar 14 is provided; the horizontal side of the transmission shaft 4 is provided with a U-shaped brake block 16 that is fixed on the die 2 shell and controlled by the brake cylinder 15 and can move forward and backward; the crankshaft 6 is vertically provided with There is a cam induction blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com