Spray printed composite plate

A composite board and inkjet technology, which is applied in the direction of synthetic resin layered products, decorative arts, special decorative structures, etc., can solve the problems of high cost, inability to meet people's needs for diversity and novelty, and insufficient practicality and innovation. Human intentions and other issues to achieve the effect of meeting the needs of use, low production cost, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

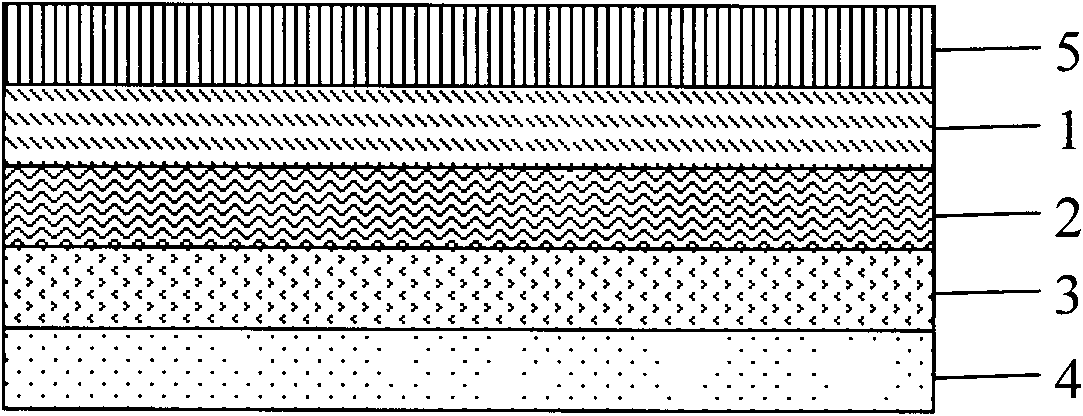

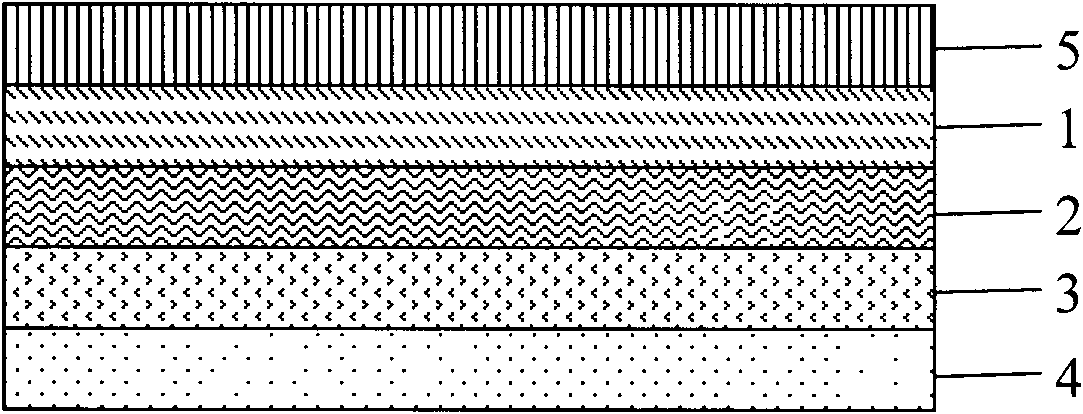

[0016] Such as figure 1 As shown, the inkjet-printed composite board is made of toughened glass as the base material. The back of the tempered glass 1 is spray-painted with a personalized pattern layer 2. There is a printed layer 3 on the personalized pattern layer 2. The printed layer 3 is coated with polyurethane foam and bonded. The coating 4 is covered with a protective film layer 5 bonded to the front of the toughened glass.

[0017] Using traditional tempered glass as the base material, according to personal preferences, spray-paint a personalized pattern layer on the back of the tempered glass 1. There is a printing layer on the personalized pattern layer, and a polyurethane foam bonding coating is coated on the printing layer.

[0018] The above-mentioned inkjet-printed composite board has the usability of avoiding the use of ordinary appearance materials and cannot change the appearance design according to the user's wishes. The appearance of the tempered glass can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com