Impression roller

A technology of pressure roller and conveying device, applied in the field of pressure roller, can solve problems such as high cost and inability to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

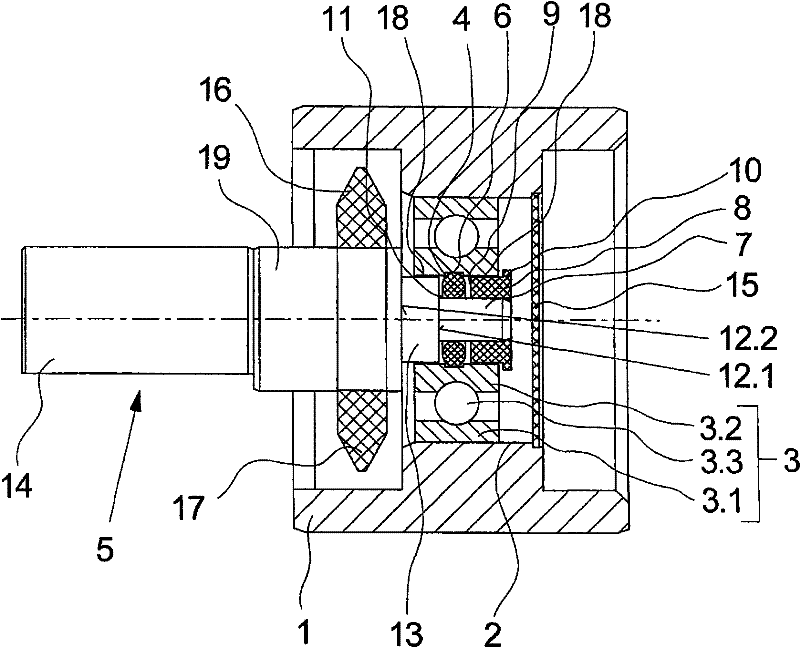

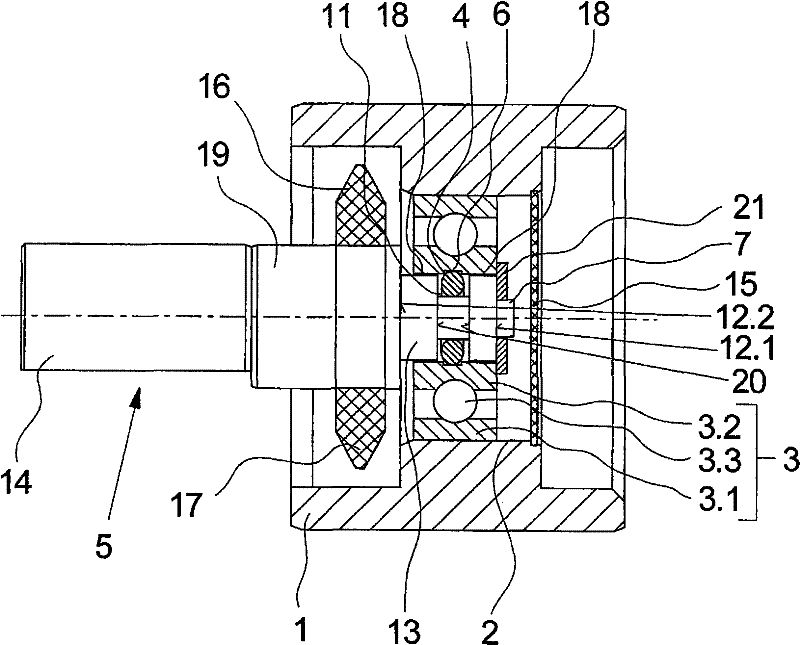

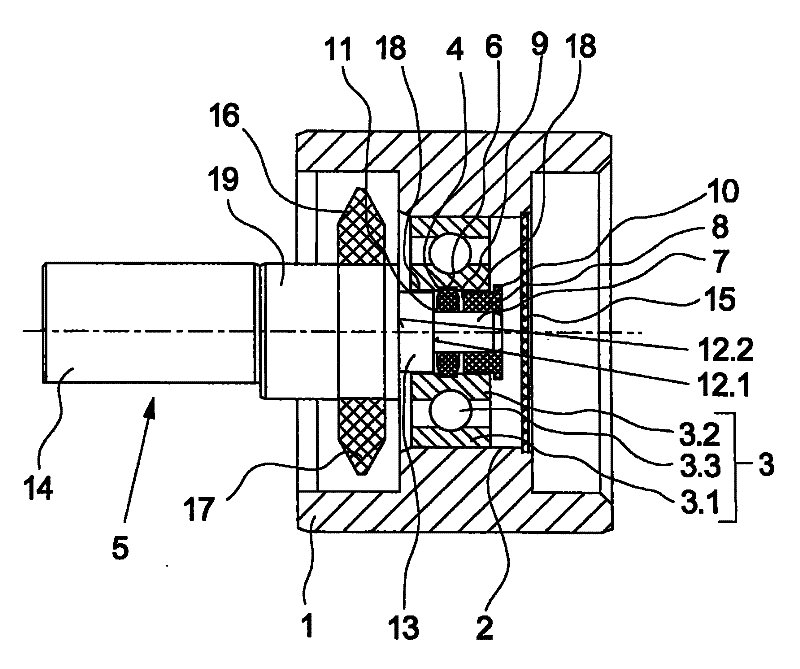

[0021] according to figure 1 The pressure roller of the exemplary embodiment has a hollow-cylindrical roller shell 1 with a hub 2 in the central region. In this embodiment, the roll shell 1 and the hub 2 are designed in one piece. In principle, however, the hub 2 of the roll shell 1 can also be formed from a plurality of individual parts.

[0022] The roller shell 1 is connected in a rotationally fixed manner via a hub 2 to a rolling bearing 3 . For this purpose, the rolling bearing 3 has an outer ring 3 . 1 which is coupled to the hub 2 in a rotationally fixed manner. In addition to the outer ring 3.1, the rolling bearing 3 also includes an inner ring 3.2 and a plurality of rolling elements 3.3 arranged between the outer ring 3.1 and the inner ring 3.2.

[0023] The inner ring 3 . 2 of the rolling bearing 3 is penetrated by the bearing end 7 of the shaft 5 . The bearing end 7 bears an elastic washer 4 . For this purpose, a limiting groove 11 is formed between the shoulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com