Aqueous environment-friendly paint with high anticorrosive performance

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high odor, high pollution, serious environmental pollution, etc., and achieve good mechanical and chemical protection, good adhesion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

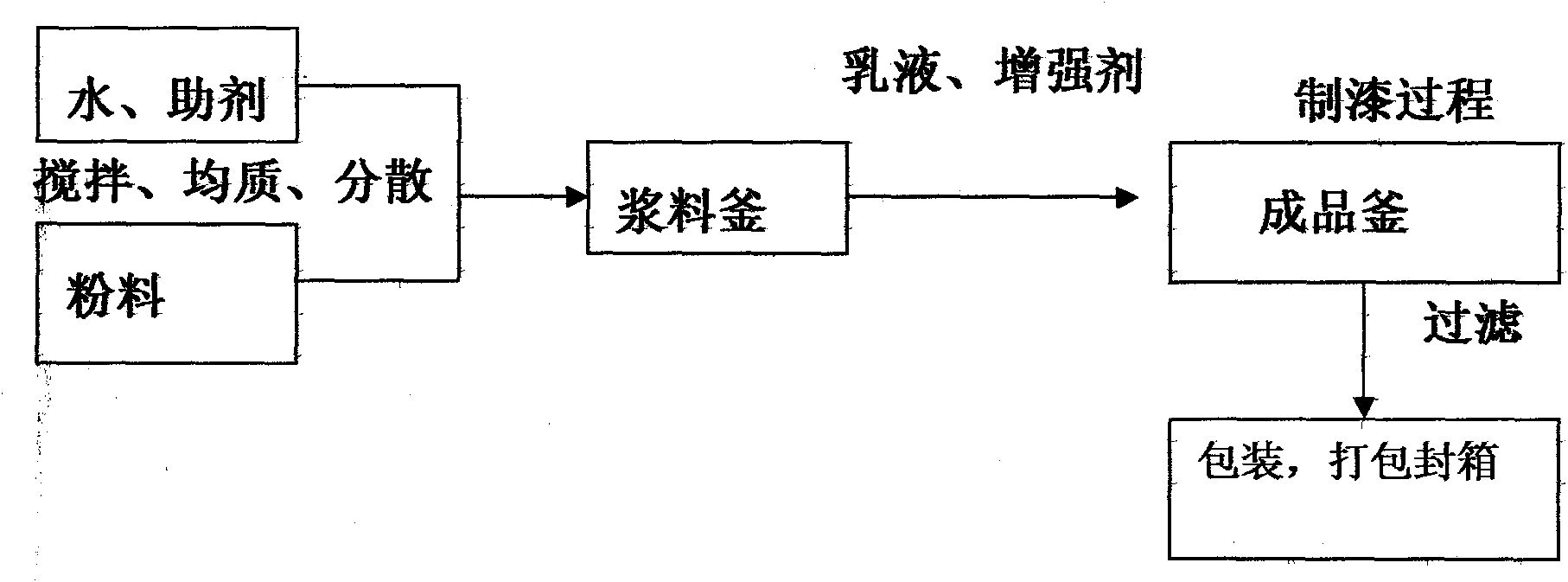

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of material A-emulsion part;

[0022] ① Emulsify the functional monomers styrene, acrylic acid, butyl acrylate, methyl methacrylate with water and OP-10, and add PH regulator and protective agent into the reaction kettle.

[0023] ② Add quantitative initiator potassium persulfate to the main reaction kettle where part of the emulsion is put into, and raise the temperature to 70-80°C;

[0024] ③Under stirring, carry out polymerization, then gradually add the remaining emulsion and initiator to initiate, add cross-linking agent N-methylolacrylamide during the initiation process, and continue to react for 3 hours to finish dripping.

[0025] ④ Under stirring, add redox agents ammonium persulfate and sodium bisulfite for post-treatment. Raise the temperature by 5-10 degrees, and then react for 1.5 hours.

[0026] ⑤ Cool down below 50 and filter.

[0027] ⑥Place it in a storage tank for later use.

[0028] 2) Preparation of B material-powder dispersion par...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap