Electronic brake for braking by utilizing kinetic energy of vehicles

A brake and kinetic energy technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of reducing vehicle driving range, increasing energy consumption, etc., to improve braking reliability, improve braking efficiency, The effect of improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

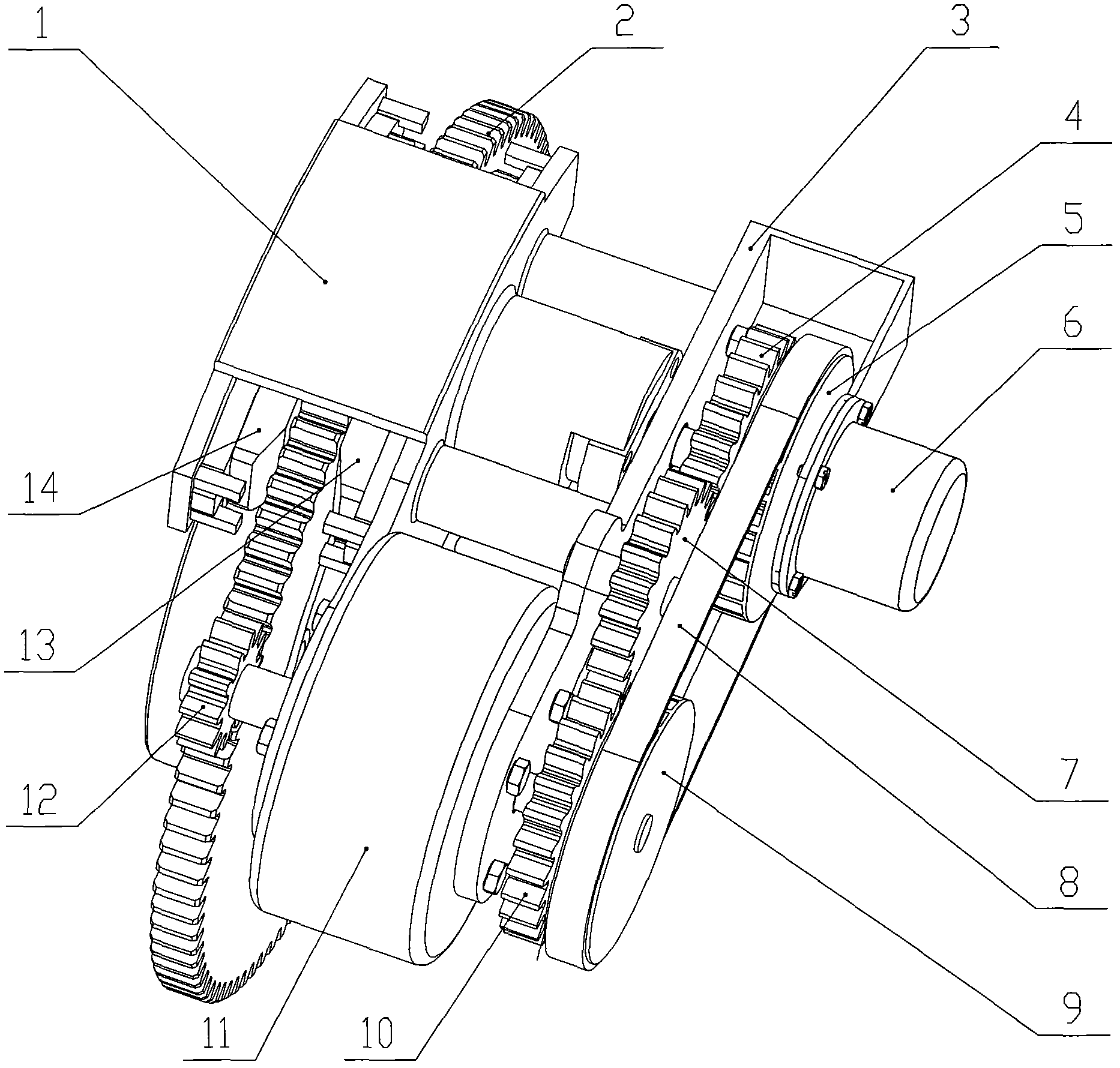

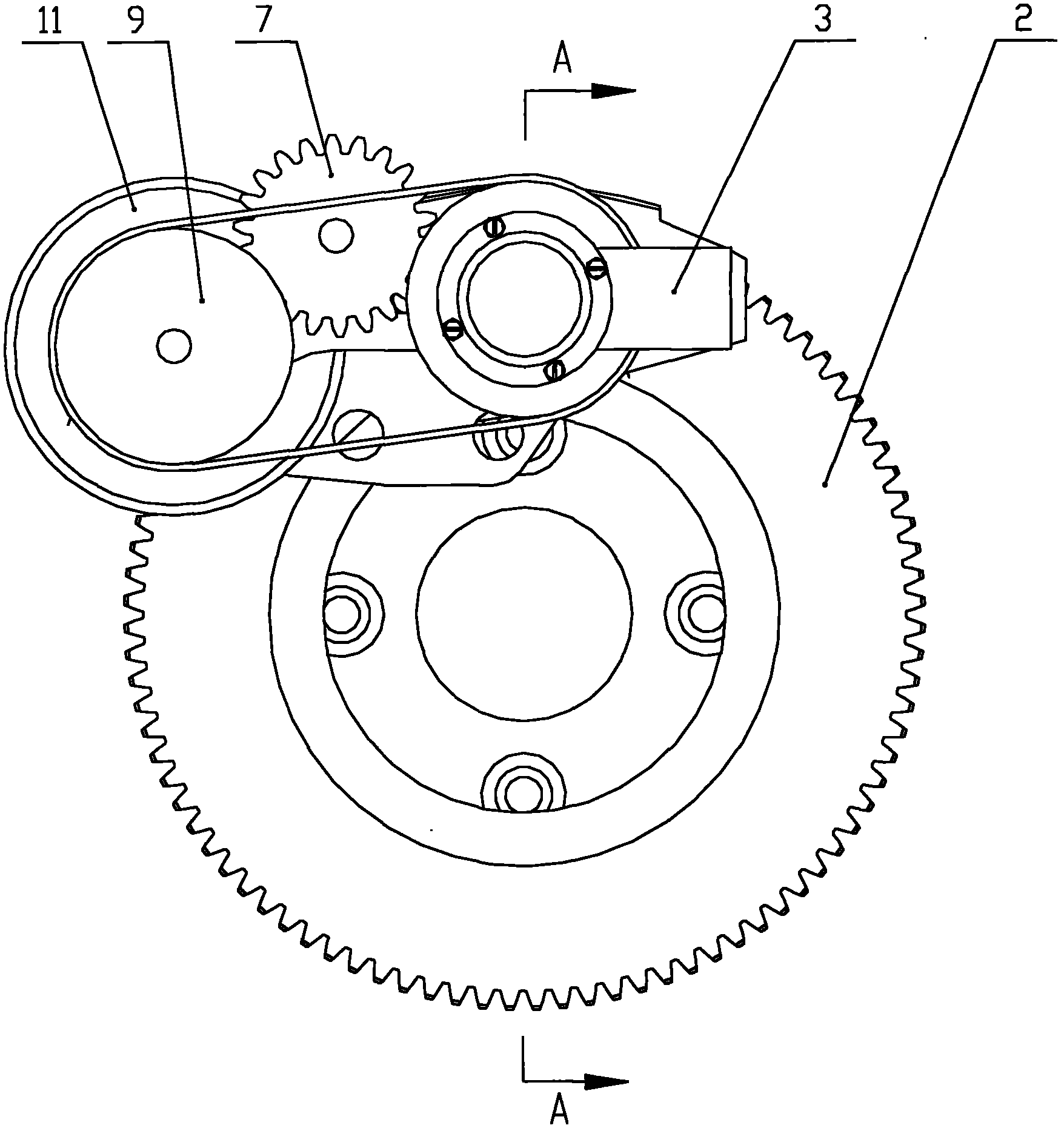

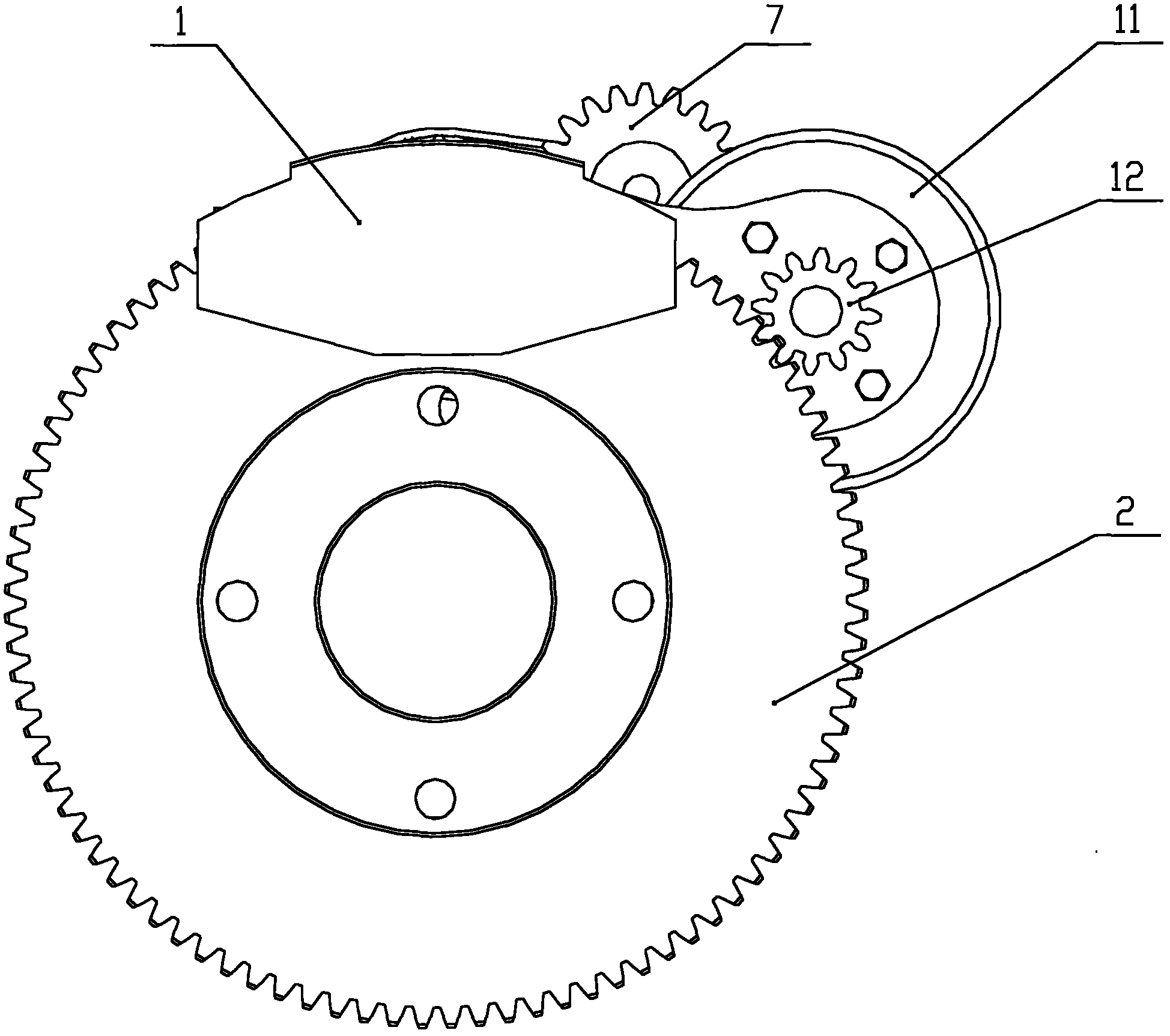

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0021] An electronic brake that utilizes vehicle kinetic energy for braking, consisting of a caliper 1, a brake disc 2, a bracket 3, a front left gear 4, a front right gear 5, a servo motor 6, a reversing gear shaft 7, a timing belt 8, and a rear right Gear assembly 9, rear left gear assembly 10, magneto-rheological clutch 11, power take-off gear shaft 12, right friction plate 13, left friction plate 14, lead screw nut 15, wear-resistant sleeve 16, lead screw rod 17, piston 18 and The controller 19 consists of the caliper 1 mounted on the vehicle frame, the brake disc 2 fixedly mounted on the axle, the right friction plate 13 and the left friction plate 14 respectively installed on the guide rail of the caliper 1 and arranged on the two sides of the brake disc 2 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com