Electric automobile hub hydraulic motor driving system

A technology for hydraulic motors and electric vehicles, applied in motion deposition, power units, vehicle components, etc., can solve the problems of complex wheel-side mechanism structure, inflexible motor and power supply space layout, large unsprung mass, etc., and achieve light weight. , eliminating the need for reducer and differential, the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

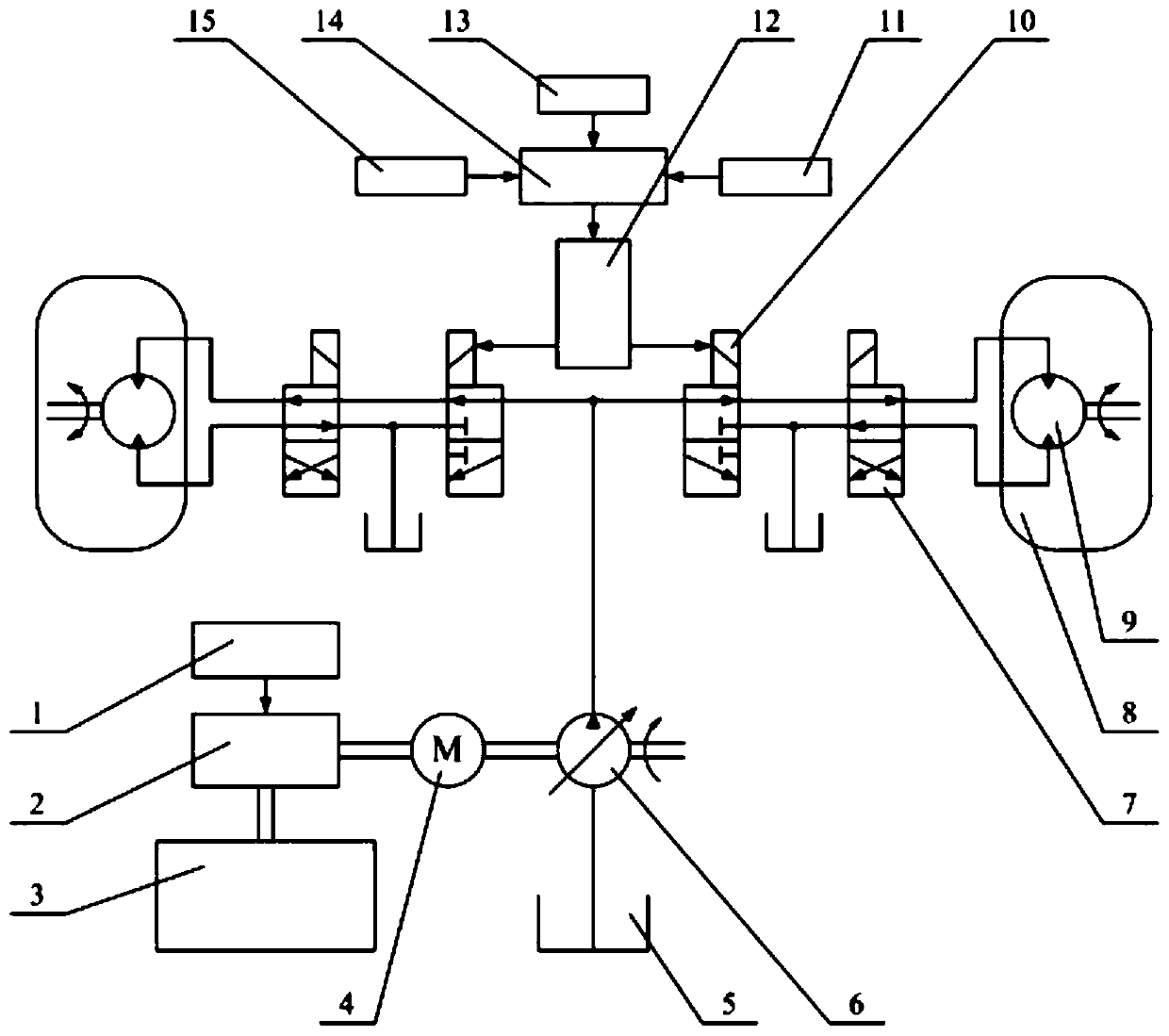

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] The present invention is an electric vehicle hub hydraulic motor drive system, including wheels 8, battery pack 3, DC / DC converter 2, motor 4, electronic control unit 1, hydraulic transmission system and continuously variable automatic control system. Among them, the hydraulic transmission system includes a fuel tank 5 connected through oil pipes, a one-way variable pump 6, two high-speed switching valves 10 for the left and right wheel circuits, two reversing valves 7 and two wheel hub hydraulic motors 9, the one-way variable The pump 6 is a plunger one-way variable pump, the high-speed switch valve 10 is an electromagnetic two-position three-way high-speed switch valve, the reversing valve 7 is an electromagnetic two-position four-way reversing valve, and the hydraulic motor 9 is an electromagnetic two-position four-way reversing valve. What is the ball plug type i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com