Wood frame-log cabin type wall mixing structure system

A technology of dry wall and hybrid structure, which is applied in the direction of walls, building components, building structures, etc. It can solve the problems of undiscovered frame-shear wall structures, reduce uneven settlement, and eliminate the loss of screw preload , Improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

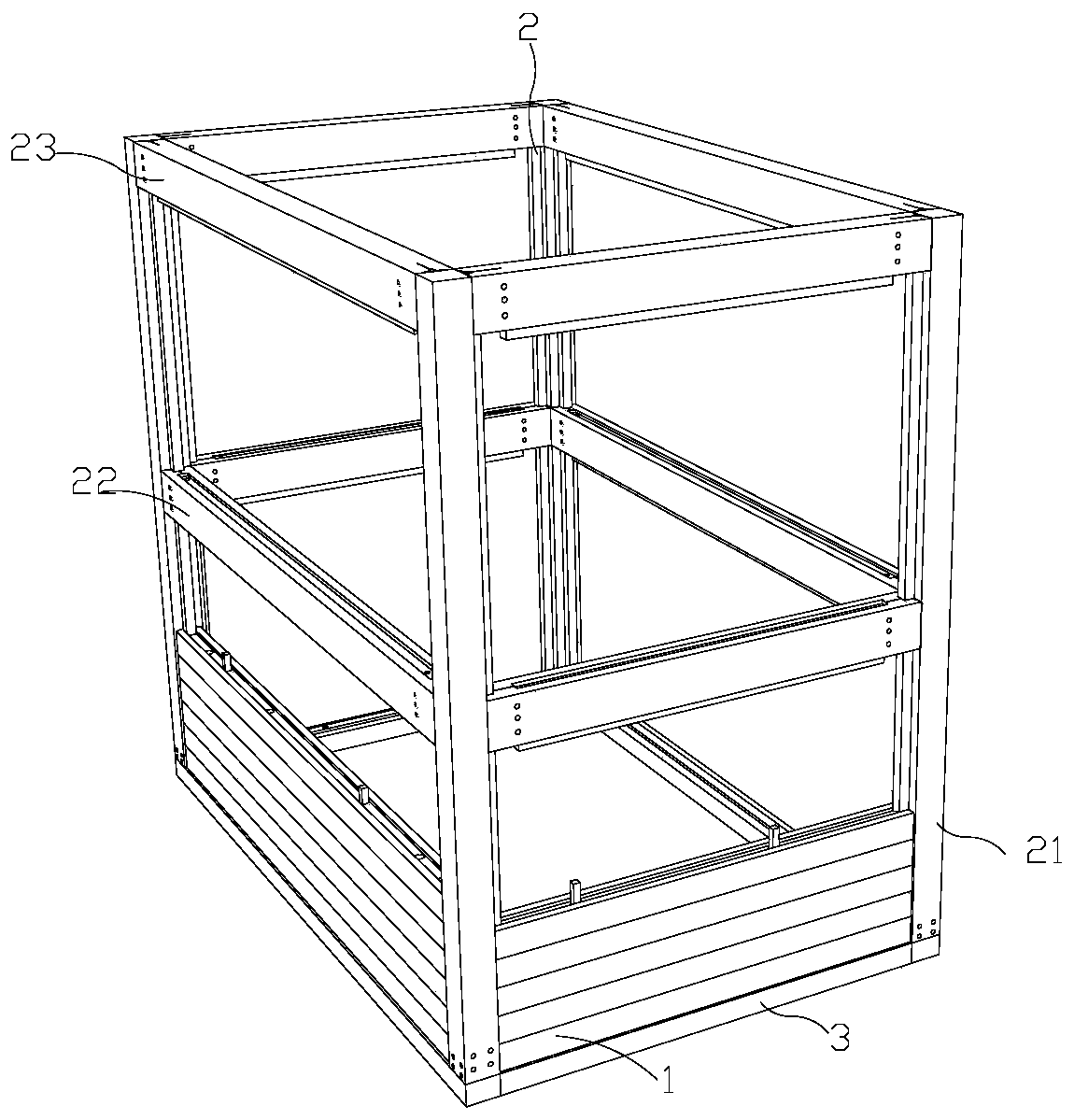

[0033] Such as figure 1 As shown in Figure 8, the wood frame-well drywall hybrid structure system includes well drywall 1, wooden columns 21, wooden beams 22 or 23, wall penetration screws 6, anchor bolts 9 and interlayer Wall anchor screw 11;

[0034] The wooden column 21 and the wooden beams 22 and 23 form a beam-column wooden frame, and the wooden column 21 and the wooden beams 22 and 23 are connected by metal connectors 10 .

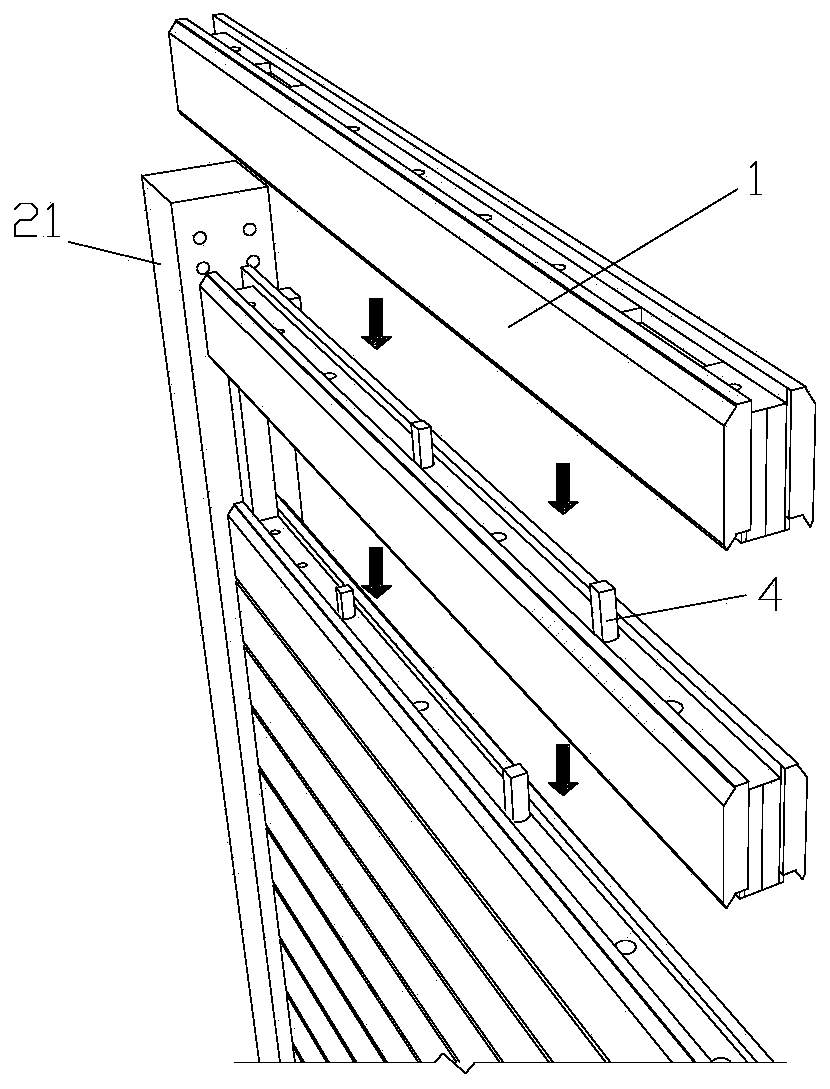

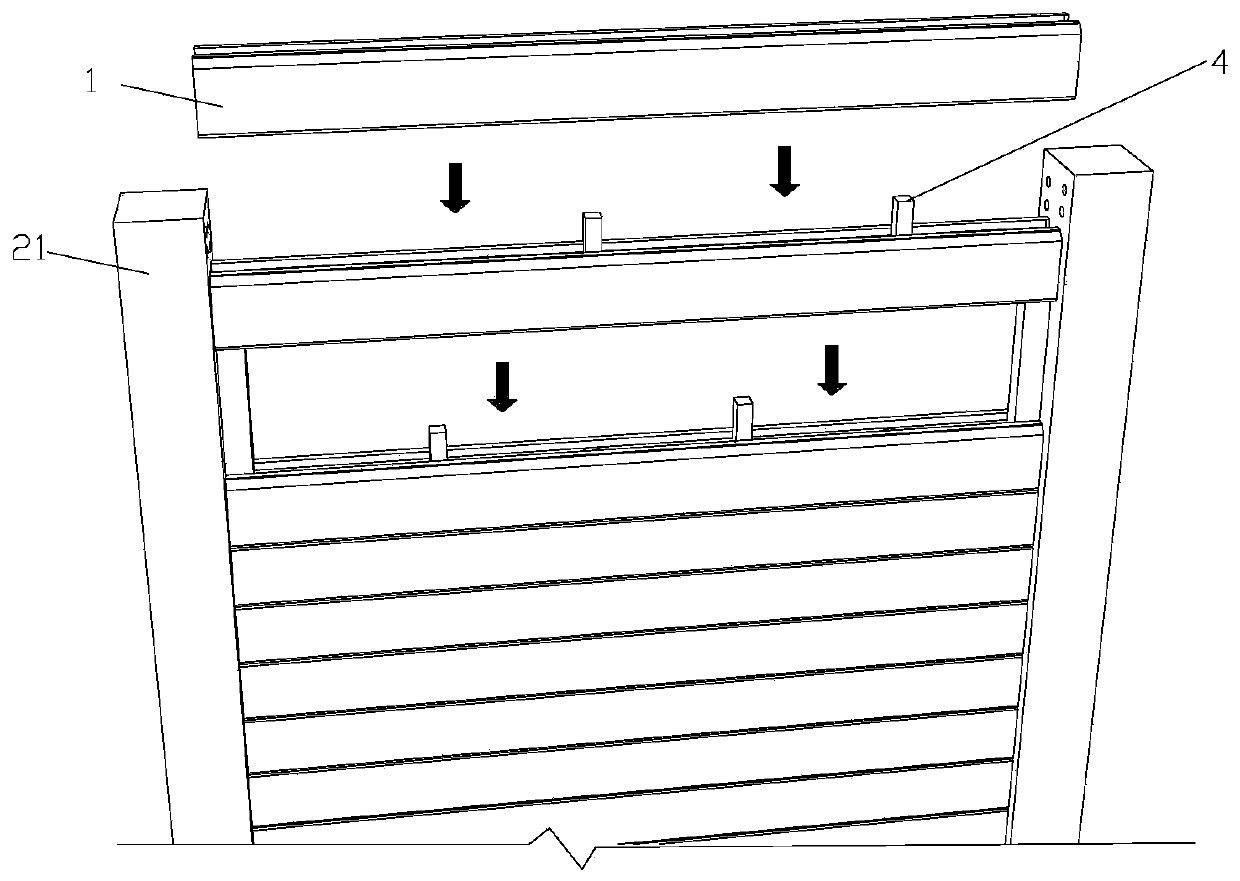

[0035] The components of the well dry wall 1 are inserted sequentially from both sides of the wooden column 21 from top to bottom, the components of the well dry wall 1 are connected in the form of tongue and groove, and the horizontal joints are provided with pressable waterproof coils. Wooden pins 4 are inserted between the upper and lower adjacent wall components, and the wooden pins 4 are misplaced. The well dry wall 1 is connected and fixed by the wall through screw 6, and a steel backing plate 5 is respectively arranged at both ends of the wa...

Embodiment 2

[0040] As shown in Figures 9-11, the difference in this embodiment is that: the wooden column 21 is provided with a rectangular notch 24 or a dovetail notch 25, and the tenons on both sides of the wall 14 are inserted into the grooves made by the wooden columns on both sides from top to bottom. In the mouth, the mortise of the wooden beam 26 is inserted into the corner posts on both sides from top to bottom, and three square wooden pins 15 with a side length of 15mm are inserted on both sides, thereby fixing the wooden beam 26.

Embodiment 3

[0042] Such as Figure 12 As shown, a wooden beam 27 is added in the middle of the body of wall 14 in the described embodiment 2, and the connection method is the same as the wooden beam 26 in the embodiment 2. After both sides are connected, insert 3 square wooden pins 15 whose side length is 15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com