Real-time acquisition experimental device for flowing foam structural images in porous media

A technology of foam structure and porous media, which is applied in the direction of testing moving fluid/granular solids, etc. It can solve the problems of not accurately reflecting the characteristics of porous media, not considering the influence of pressure on foam structure, and not being able to withstand high pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

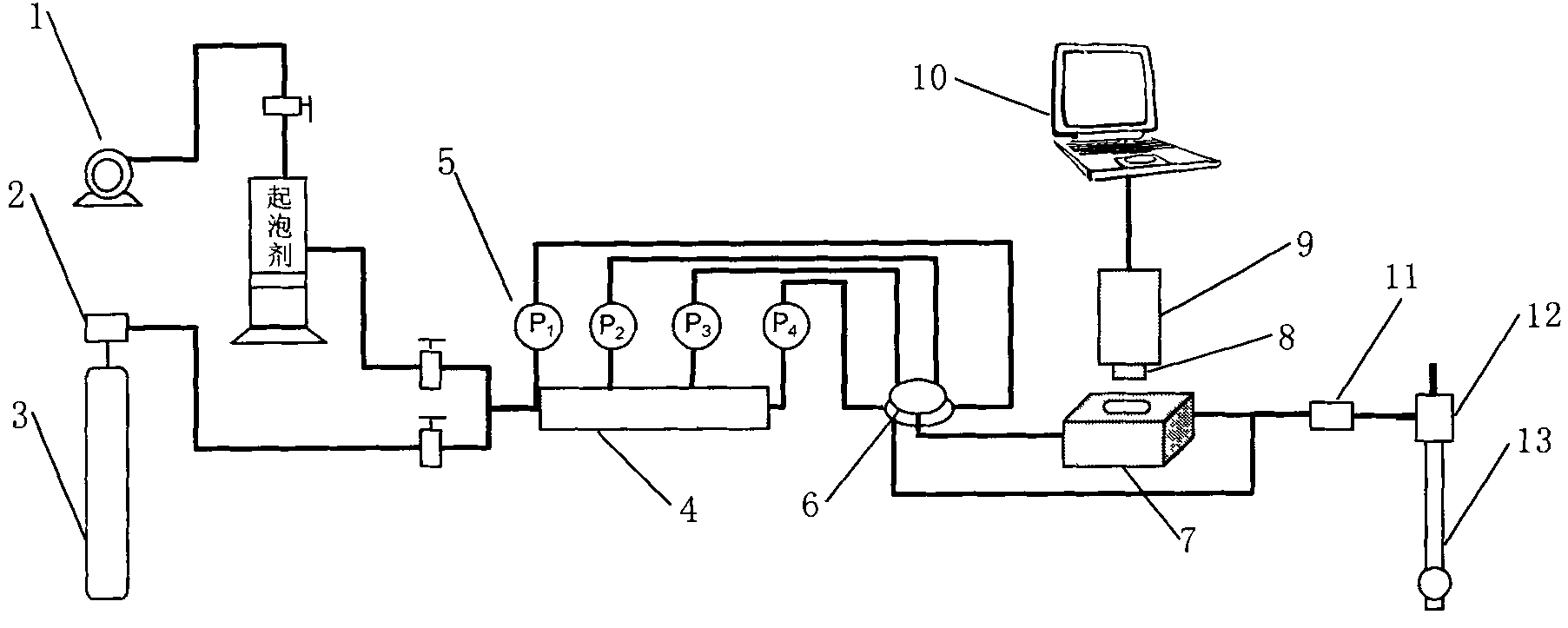

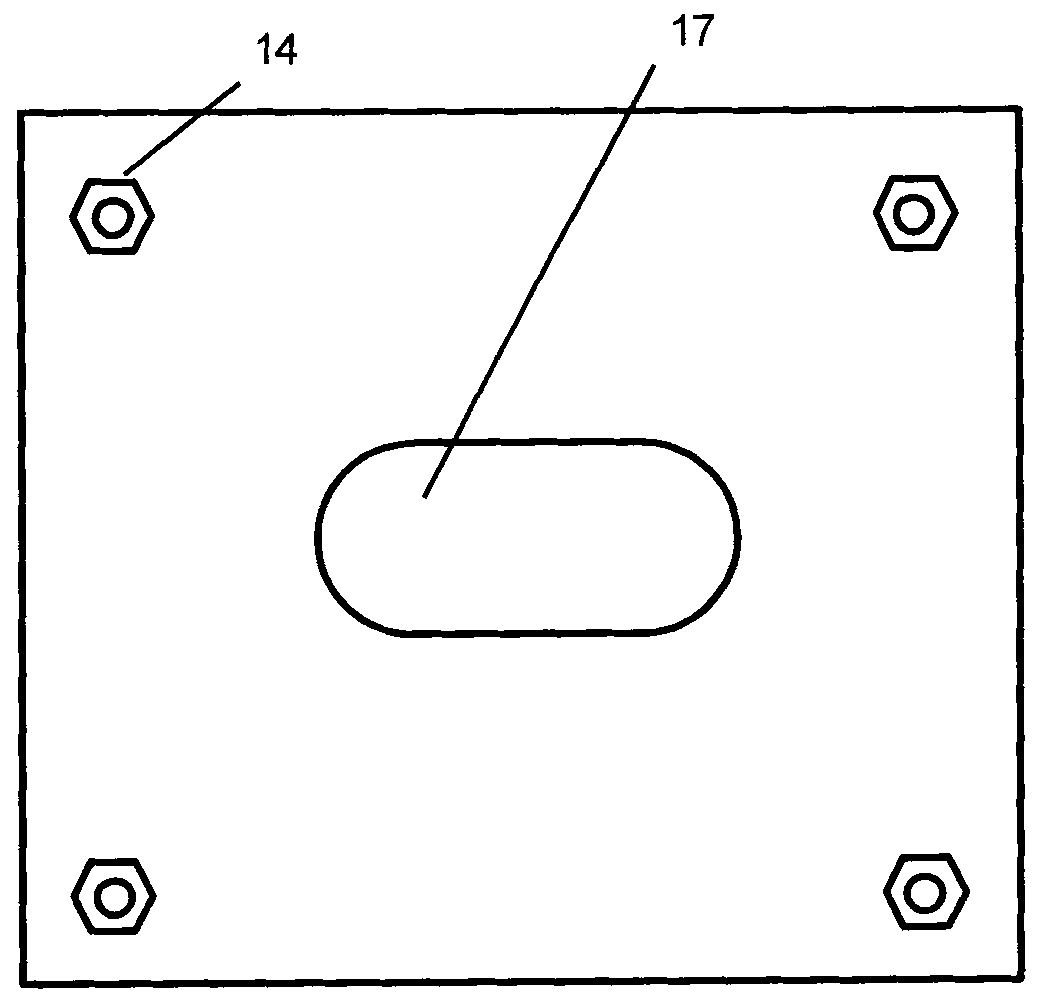

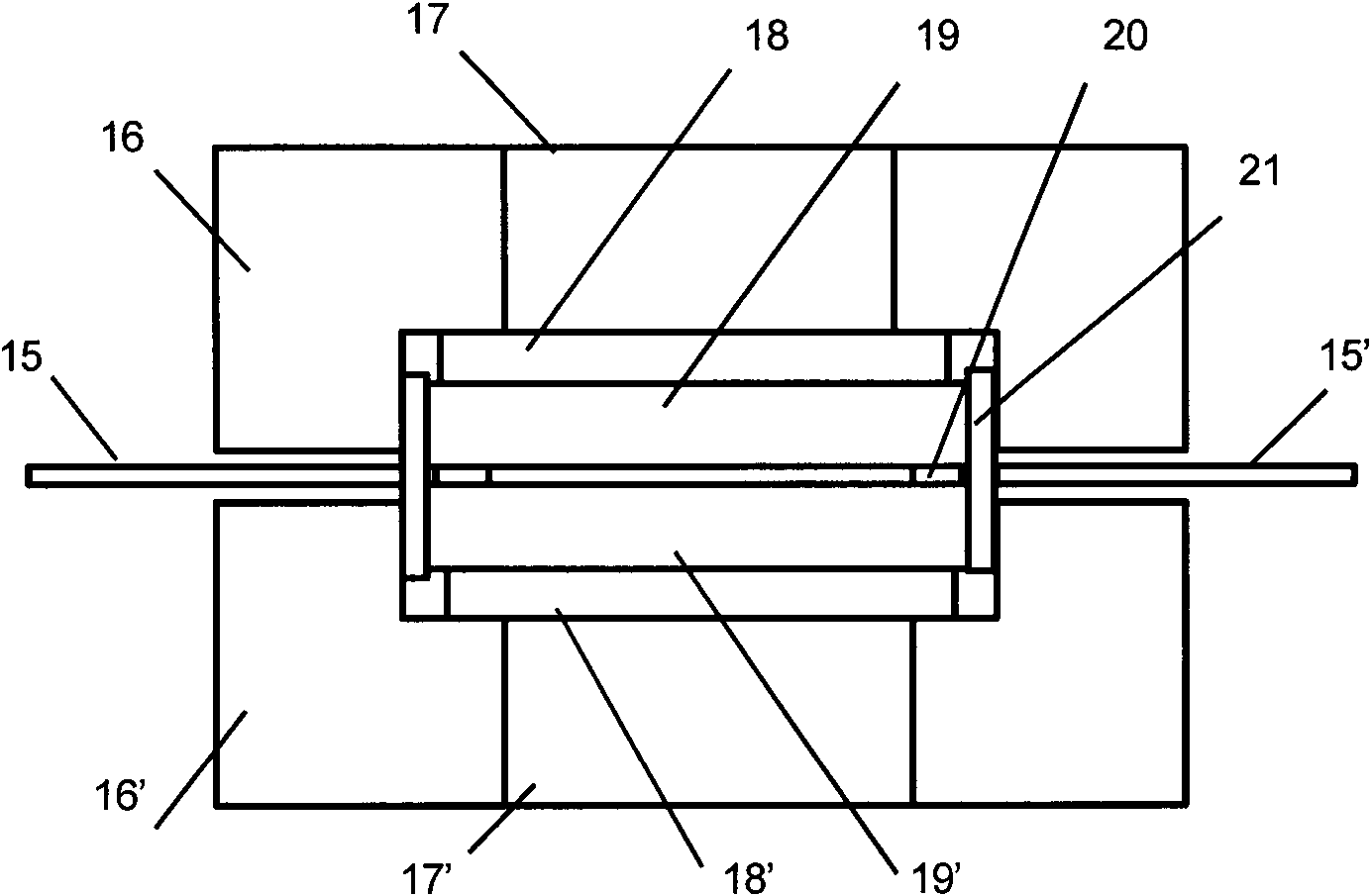

[0016] An experimental device for real-time acquisition of images of flowing foam structures in porous media, including a gas-liquid injection system, a foam seepage simulation system, an image acquisition system and an output fluid separation and metering system. Among them, the gas-liquid injection system consists of a micro advection pump 1, a gas mass flow controller 2 and a high-pressure gas cylinder 3. It is connected to the inlet of the foam seepage simulation system to provide injection conditions for generating foam; in the foam seepage simulation system, the multi-point sand filling pipe model 4 is used to generate flowing foam in porous media (rock), and the pressure at each measurement point The sensor 5 is connected to the six-way valve 6, and is used to collect the pressure of each measuring point during the experiment and to derive the foam fluid of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com