Automatic calibration system for gas sensor

An automatic calibration system and gas sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of complex work procedures, increased production costs, and low production efficiency, so as to improve production efficiency, save costs, and increase utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

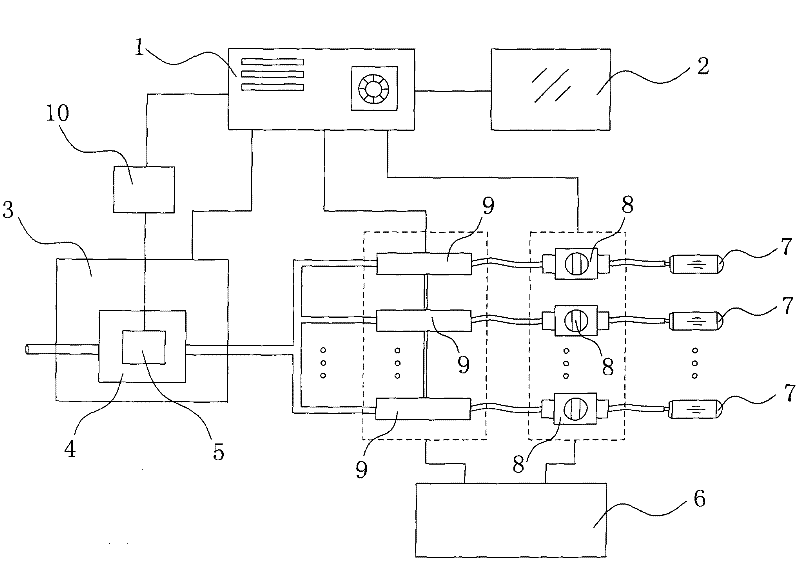

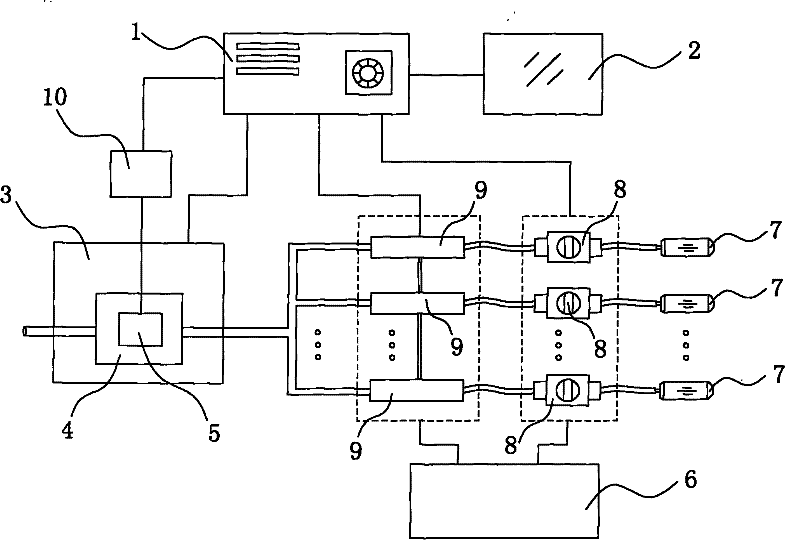

[0012] Such as figure 1 As shown, a gas sensor automatic calibration system, which includes N groups of steel cylinders 7, N groups of solenoid valves 8, solenoid valve control circuits, N groups of gas mass flow controllers 9, DC power supply 6, high and low temperature alternating test box 3, A sensor gas cover 4, a sensor data acquisition circuit 10, an industrial control computer 1, and a liquid crystal display 2 connected to the industrial control computer 1 are arranged in the high and low temperature alternating experiment box 3;

[0013] Wherein, the outlet of the steel cylinder 7 is equipped with a pressure reducing valve, the outlets of N groups of steel cylinders 7 are respectively connected to the inlets of N groups of solenoid valves 8, and the outlets of N groups of solenoid valves 8 are respectively connected to the inlets of N groups of gas mass flow controllers 9, The outlets of N groups of gas mass flow controllers 9 are connected to the inlets of the sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com