Micro-mirror device screening method, micro-mirror device screening device and no-mask exposure device

A technology of a micromirror device and a screening method, which is applied in the photoplate-making process exposure device, microlithography exposure equipment, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

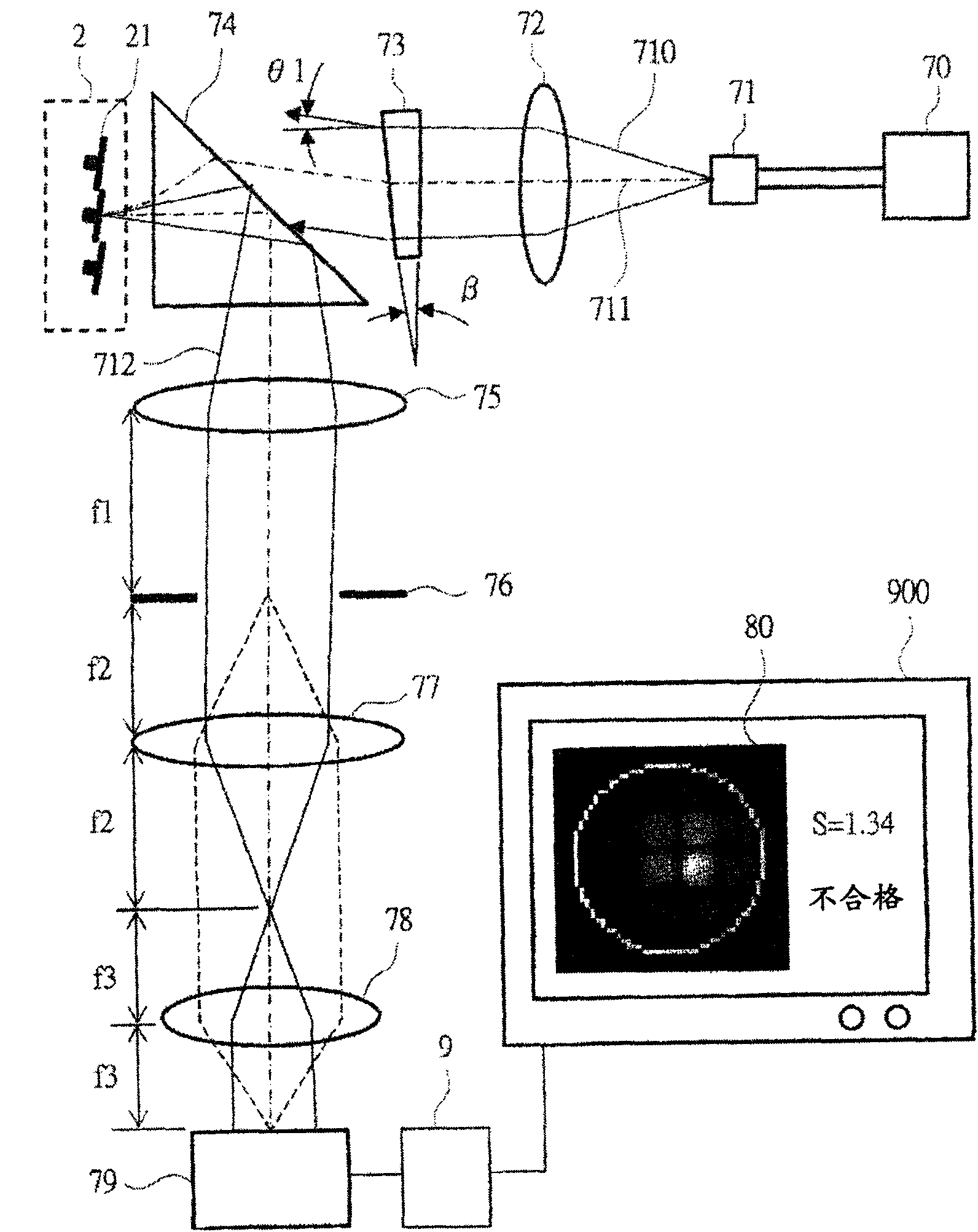

[0059] pass figure 1 The configuration of a micromirror device (hereinafter referred to as MMD) screening device according to Embodiment 1 of the present invention will be described. figure 1 It is a configuration diagram showing the configuration of the MMD screening device according to the embodiment of the present invention.

[0060] exist figure 1 Among them, the MMD screening device consists of MMD2, processing section 9, illumination system, i.e. light source 70 and optical fiber 71, collimating lens 72 as optical system, wedge-shaped glass 73, rectangular prism 74, lenses 75, 77, 78 and aperture 76, imaging element 79. The display system 900 is configured. The MMD2 is composed of a micromirror 21 .

[0061] In this embodiment, the MMD2 is irradiated with parallel light at a predetermined angle, and the reflected light is parallel-corrected through the lens, and the diffracted light distribution is shrunk and imaged on the imaging element through the lens system, a...

Embodiment approach 2

[0098] This embodiment is a form in which the MMD screening apparatus of Embodiment 1 is mounted on a maskless exposure apparatus.

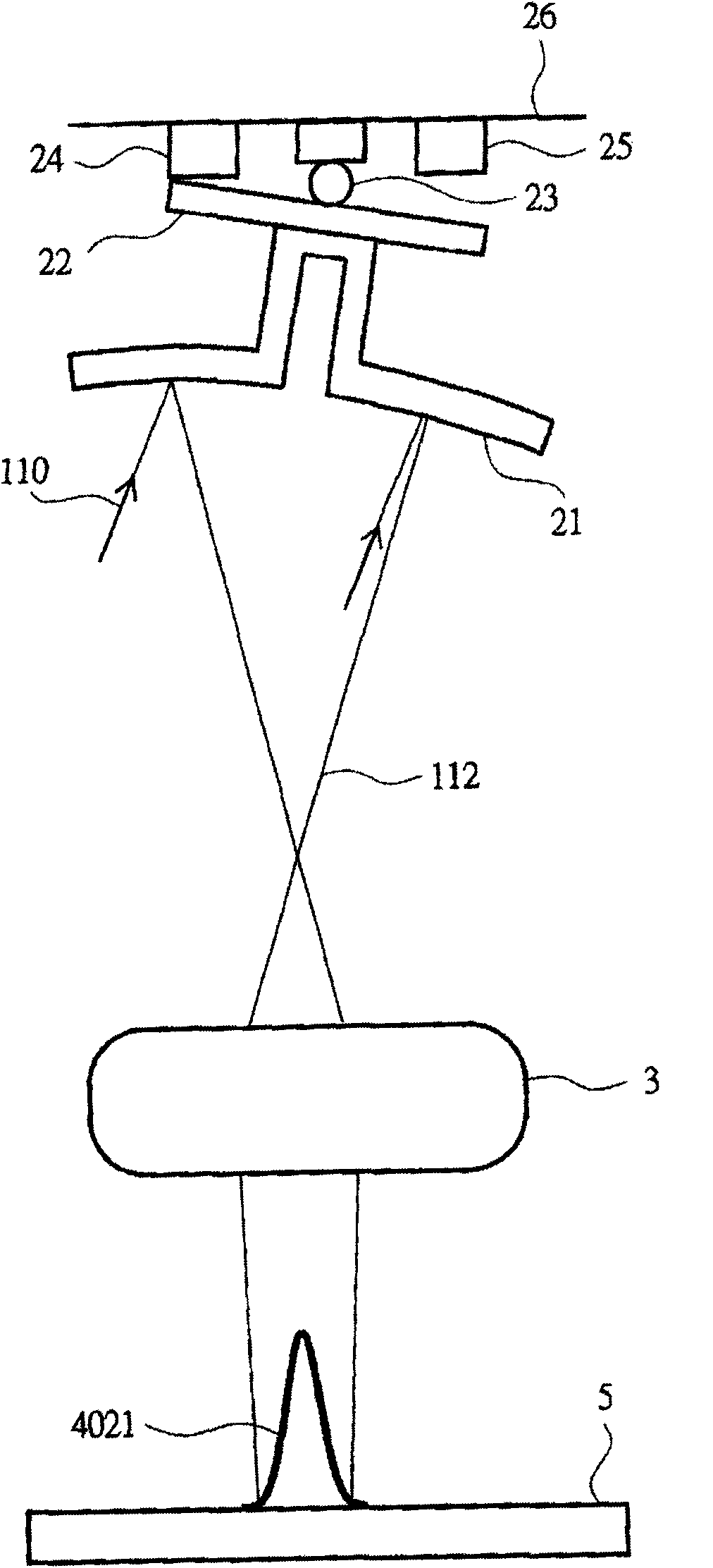

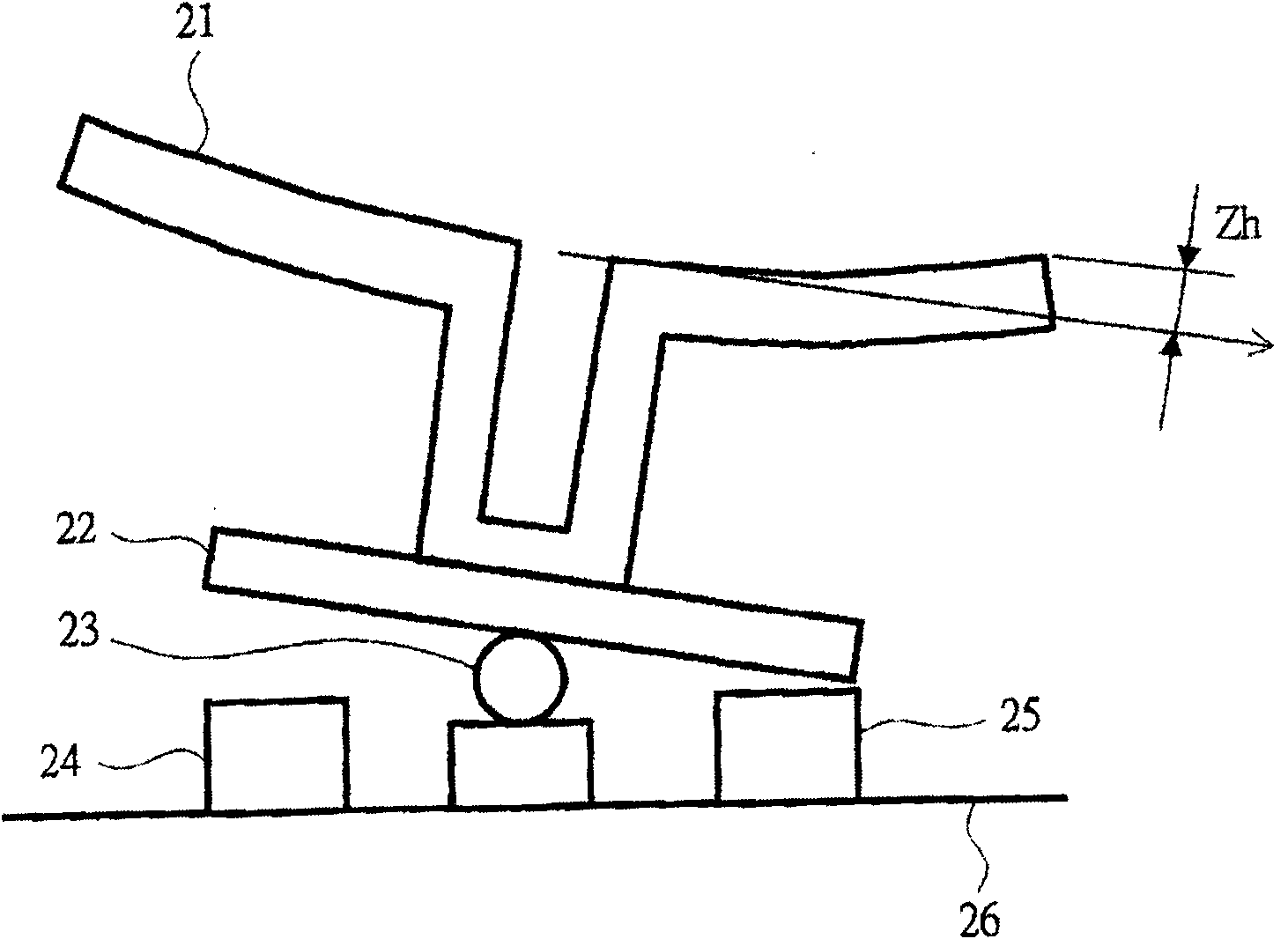

[0099] pass Figure 9 and Figure 10 The structure and operation of the maskless exposure apparatus according to Embodiment 2 of the present invention will be described. Figure 9 is a configuration diagram showing the configuration of a maskless exposure apparatus according to Embodiment 2 of the present invention, Figure 10 It is a diagram of the rotary aperture of the illumination system of the maskless exposure apparatus according to Embodiment 2 of the present invention.

[0100] In this embodiment, the diffracted light distribution is monitored on a maskless exposure apparatus.

[0101] exist Figure 9 In, maskless exposure setup with figure 1 The shown MMD screening device is the same, has: MMD2, processing system 9, light source 70, optical fiber 71, collimating lens 72, wedge-shaped glass 73, rectangular prism 74, lens 75,77,78, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com