Cutting or welding robot

A welding robot and cutting torch technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high manufacturing cost, difficult manufacturing of welding groove cutting machine, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

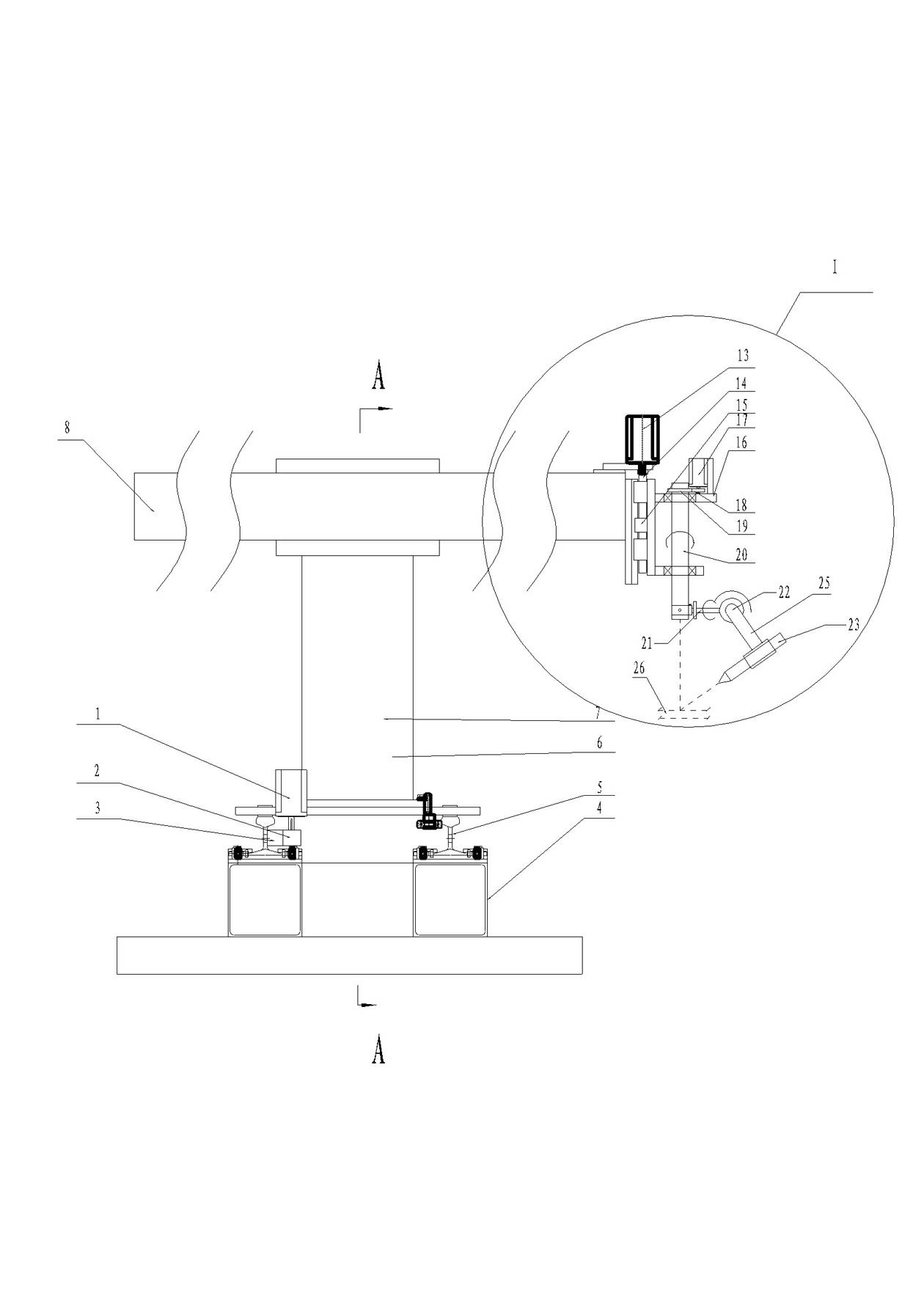

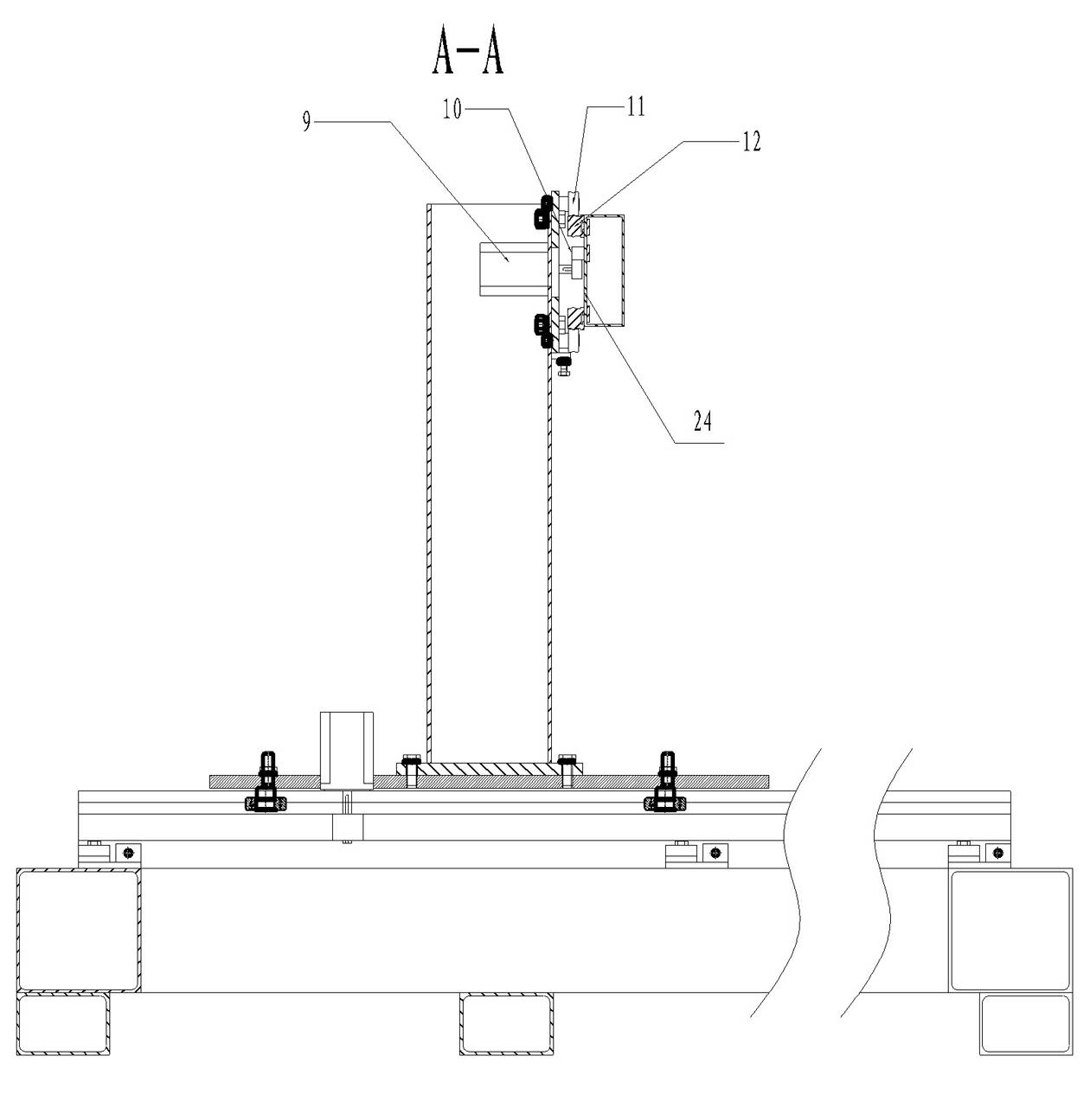

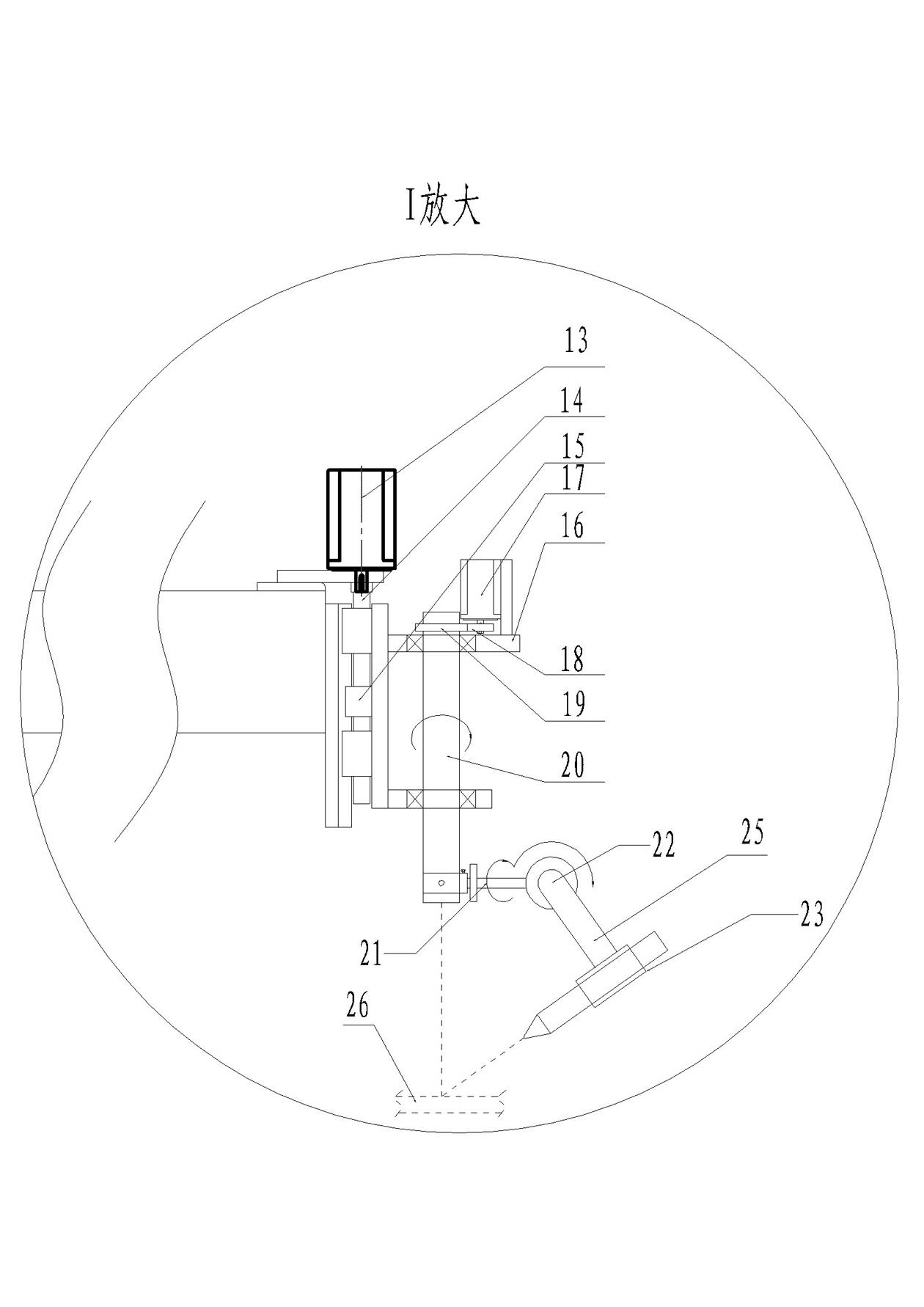

[0016] Example Figure 1~3 As shown: the cutting or welding robot includes a base 4, and the two directions perpendicular to each other on the horizontal plane are respectively defined as the X direction and the Y direction, and the vertical direction is defined as the Z direction. The upper surface of the base is along the The Y direction is provided with a cutting torch longitudinal linear motion mechanism 7, and the machine base 4 is provided with a longitudinal guide rail 5 for the assembly of the cutting torch longitudinal linear motion mechanism 7. The longitudinal guide rail 5 is provided with a longitudinal rack 3, and the first drive motor 1 passes through the second A gear 2 cooperates with the longitudinal rack 3 to realize the longitudinal linear movement mechanism 7 of the cutting torch to move in the Y direction. The longitudinal linear movement mechanism 7 of the cutting torch also includes a longitudinal slide plate 6, and the longitudinal slide plate 6 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com