Fully automatic stone face milling machine

A milling machine, fully automatic technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of large dust, single direction of thickness determination, large thickness error of products, etc., to achieve easy equipment operation and complete surface Smooth, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

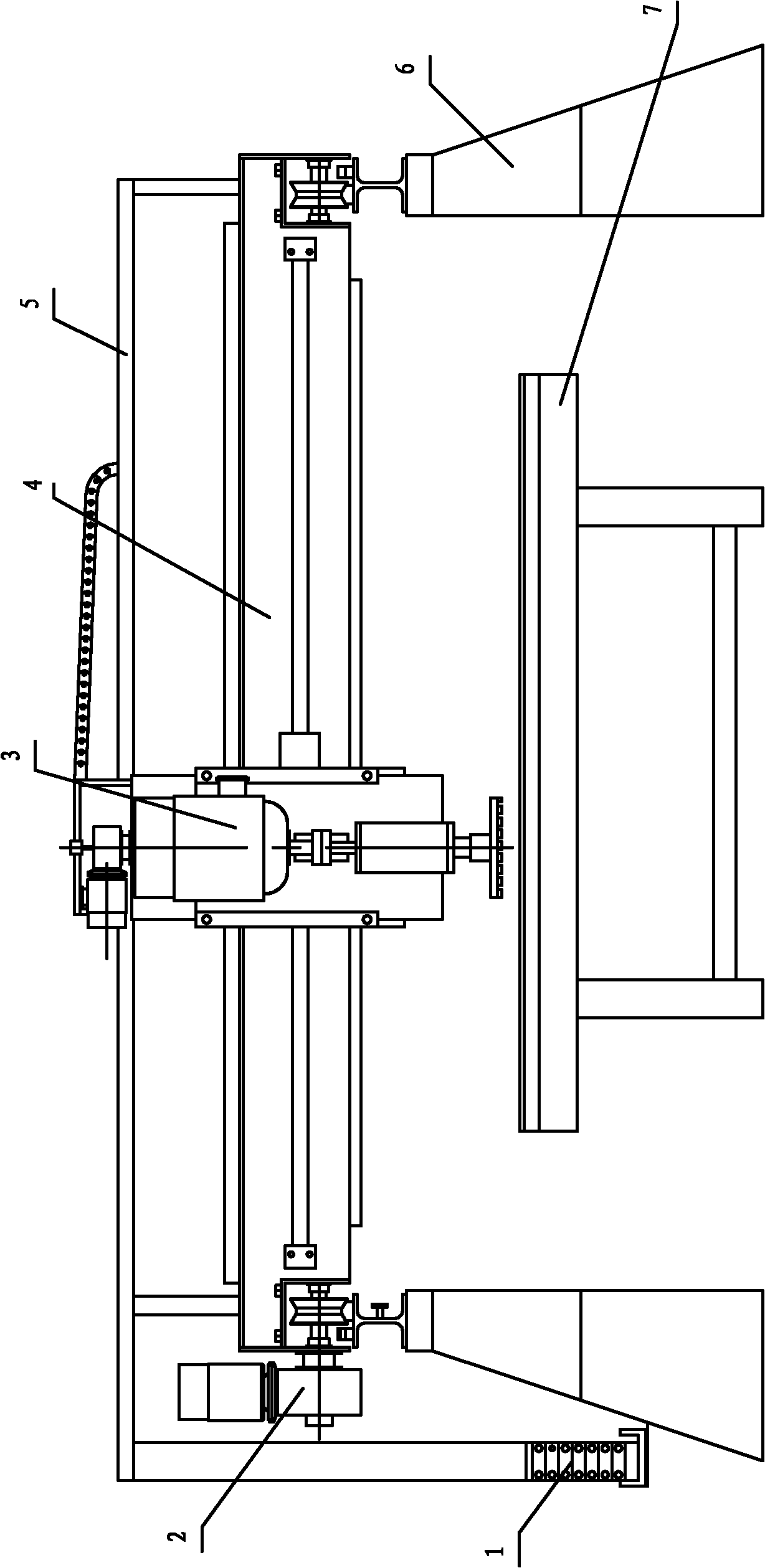

[0011] refer to figure 1 , figure 2 , image 3 As shown, the full-automatic stone milling machine is symmetrically provided with two bases 47, the base 47 is provided with an I-shaped guide rail, and a movable beam 45 and a beam drive mechanism 43 are arranged on the I-shaped guide rail. There is a tool rest 44 that can walk along the beam, and a workbench 48 is provided between the two bases 47;

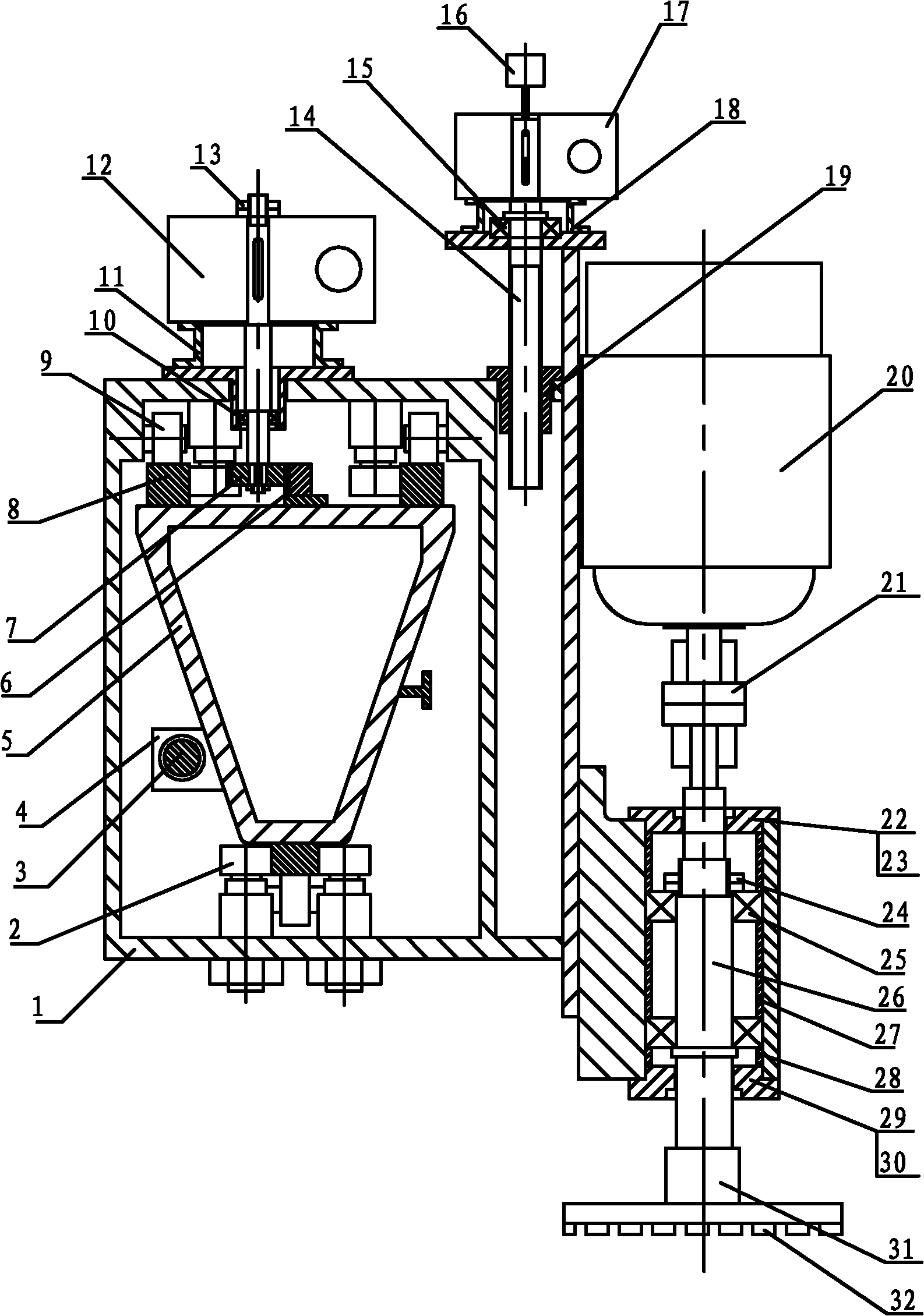

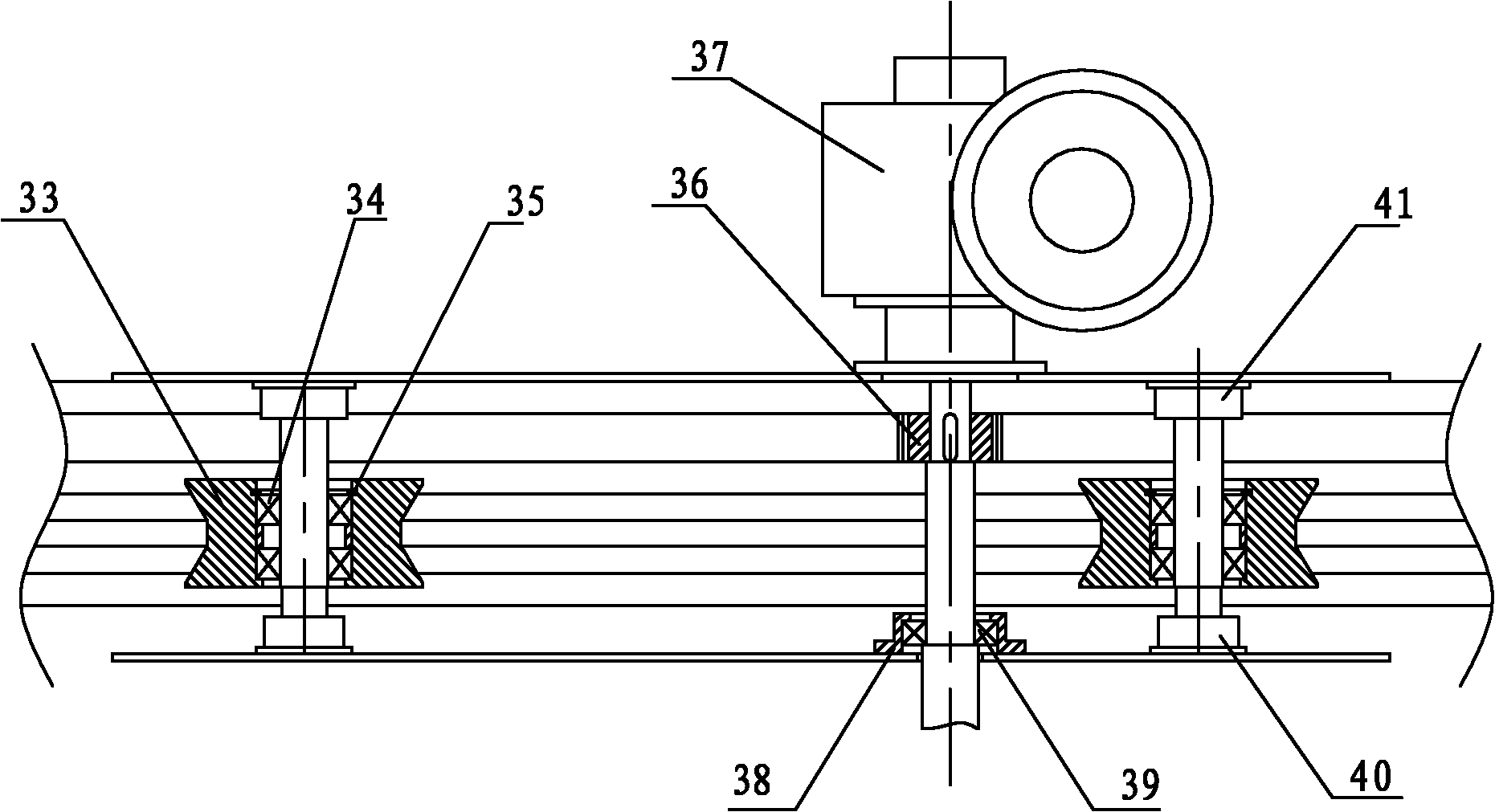

[0012] Described knife rest 44 comprises a support 1 that is installed on the described crossbeam 45, and the upper plane of crossbeam 45 is provided with two guide rails 8 symmetrically, is provided with two rollers 9 rolling on guide rail 8 correspondingly on support 1, in A rack 6 is provided on the crossbeam between the two guide rails 8, and a gear 7 meshing with the rack 6 is correspondingly provided on the bracket. The gear 7 passes through the bearing 10, and the flange 11 and a bracket 1 The reducer 12 is connected, and the other shaft end of the reducer 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com