Unfrozen heat exchanger for liquefied natural gas (LNG) automobile air conditioner

A technology for liquefied natural gas and automotive air-conditioning, applied in the field of non-freezing heat exchangers, which can solve the problems of insufficient comfort for air-conditioning systems and carbon dioxide freezing, and achieve the effects of light weight, increased heat exchange area, and convenient and flexible integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below in conjunction with accompanying drawing:

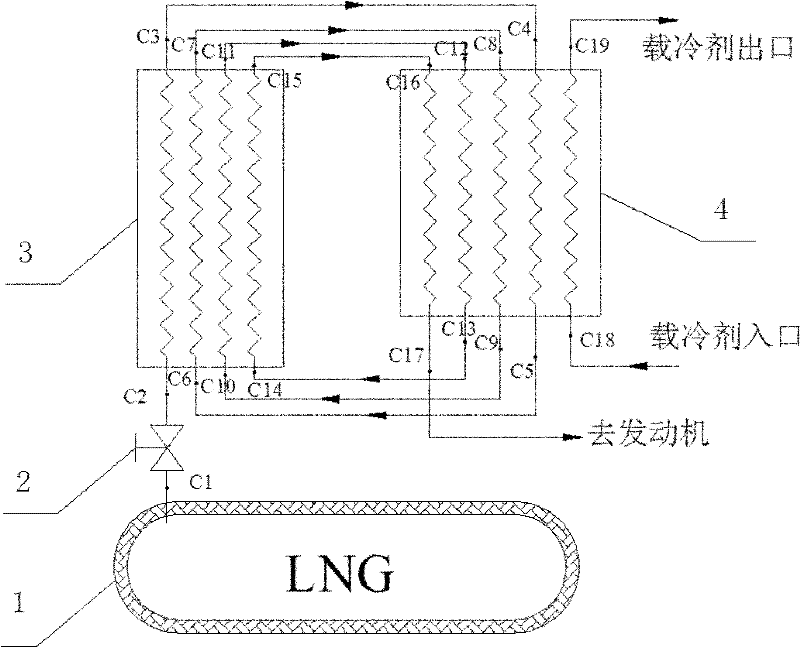

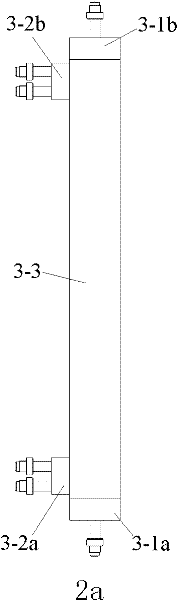

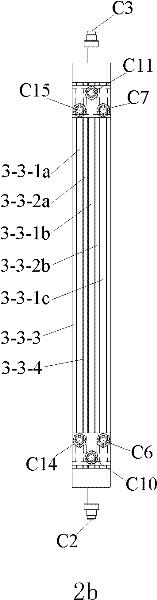

[0013] refer to figure 1 , figure 2 , image 3 , the invention discloses a non-freezing heat exchanger for LNG automobile air conditioners, which includes: a multi-channel plate-fin LNG vaporizer 3 for exchanging heat between LNG and superheated natural gas after rewarming, and an exchanging medium for superheated natural gas and refrigerant Hot plate-fin type refrigerant heat exchanger 4, wherein the multi-channel plate-fin type LNG vaporizer has flow heat exchange channels of two streams of LNG (A) and three streams of superheated natural gas (B) arranged crosswise, and the channel arrangement is BABAB type; The plate-fin brine heat exchanger has 9 streams of brine (C) and 8 streams of superheated natural gas (B) flow heat exchange channels arranged crosswise, and the channel arrangement type is CBCBCBCBCBCBCBCBC.

[0014] refer to figure 1 The working principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com