Hybrid LED (light-emitting diode) backlight source drive method

A technology of LED backlight source and driving method, applied in instruments, static indicators, etc., can solve the problems of poor white brightness uniformity, high cost, low cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

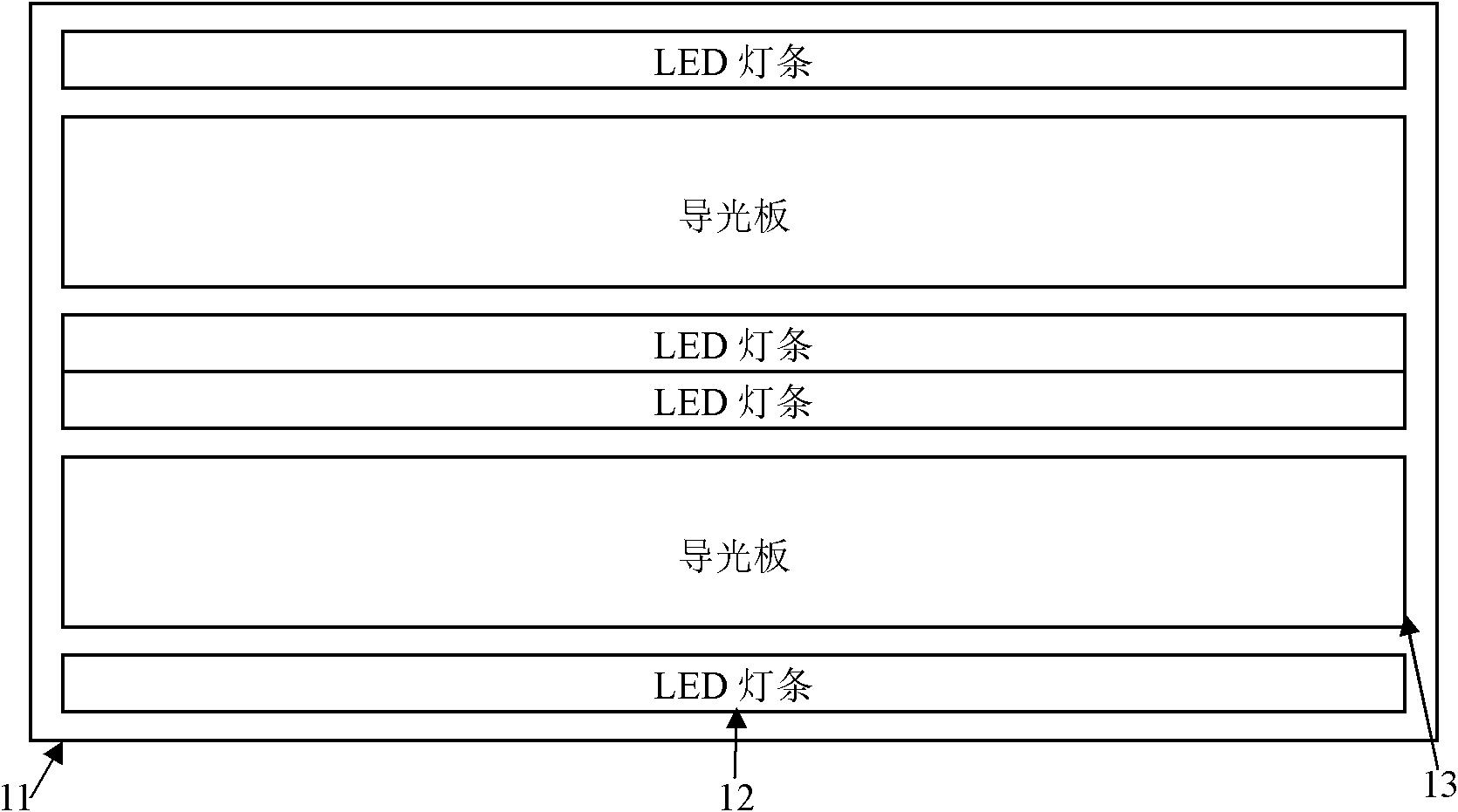

[0013] Such as figure 1 As shown, the device of the present invention includes an LED backlight frame 11 , an LED light bar 12 , and a light guide plate 13 .

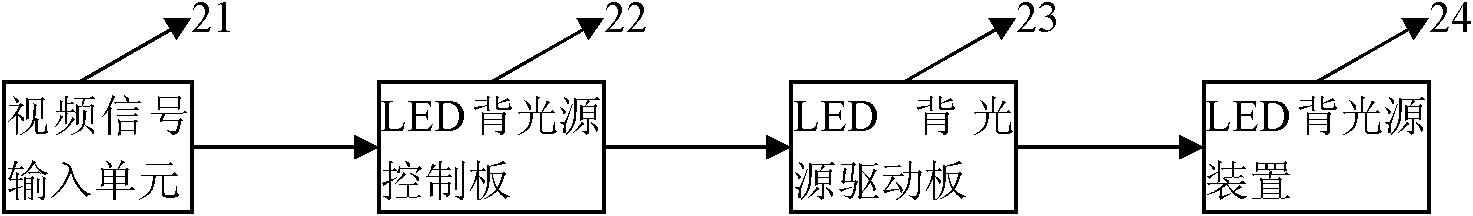

[0014] Such as figure 2 As shown, the hybrid LED backlight driving method includes a video signal input unit 21 , an LED backlight control board 22 , an LED backlight driving board 23 , and an LED backlight device 24 .

[0015] The specific implementation steps of the hybrid LED backlight driving method are as follows:

[0016] 1. According to the physical resolution of the LCD screen and actual needs, divide the entire LCD screen into M times N areas, for example, a screen with a resolution of 1920 x 1080 can be divided into 4 times 3 areas according to the cost and display effect requirements .

[0017] 2. The LED backlight device 24 is divided into corresponding M times N areas according to the division method of the liquid crystal screen, and each area is equivalent to an edge-lit LED backlight unit. figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com