Method for producing terminal for electronic component, and terminal for electronic component produced by the production method

A technology of electronic parts and manufacturing methods, which is applied in the direction of capacitor terminals, capacitor parts, electrical components, etc., can solve problems such as the inability to use lead-free tinned copper wires, the inability to improve the bonding strength of copper leads and aluminum electrodes, and achieve good bonding intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

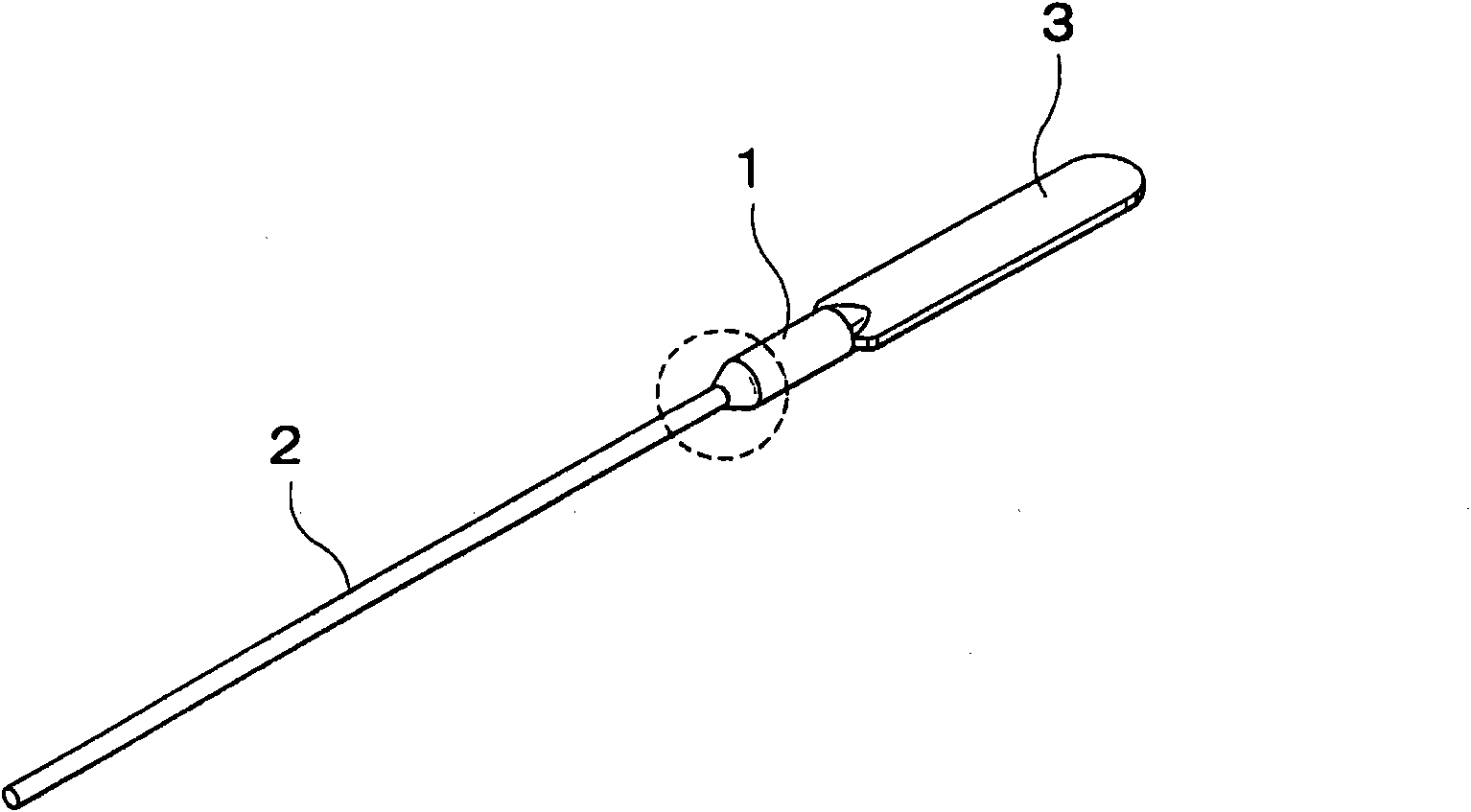

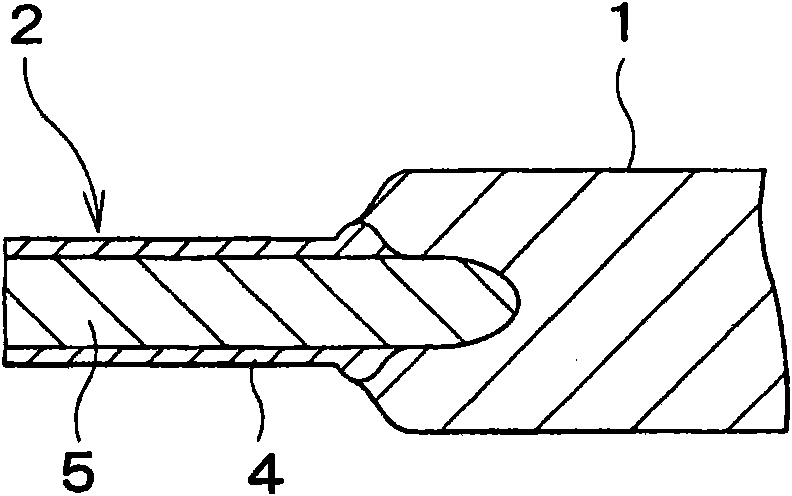

[0050] As the lead terminal member, a 0.6 mmφ copper lead wire to which lead-free tin plating (plating thickness: 12 μm) was applied was used, and the lead copper wire was cut into a length of 20 mm. In addition, as an aluminum electrode terminal member, an aluminum wire of 1.2 mmφ was used, and the aluminum wire was cut into a length of 9 mm.

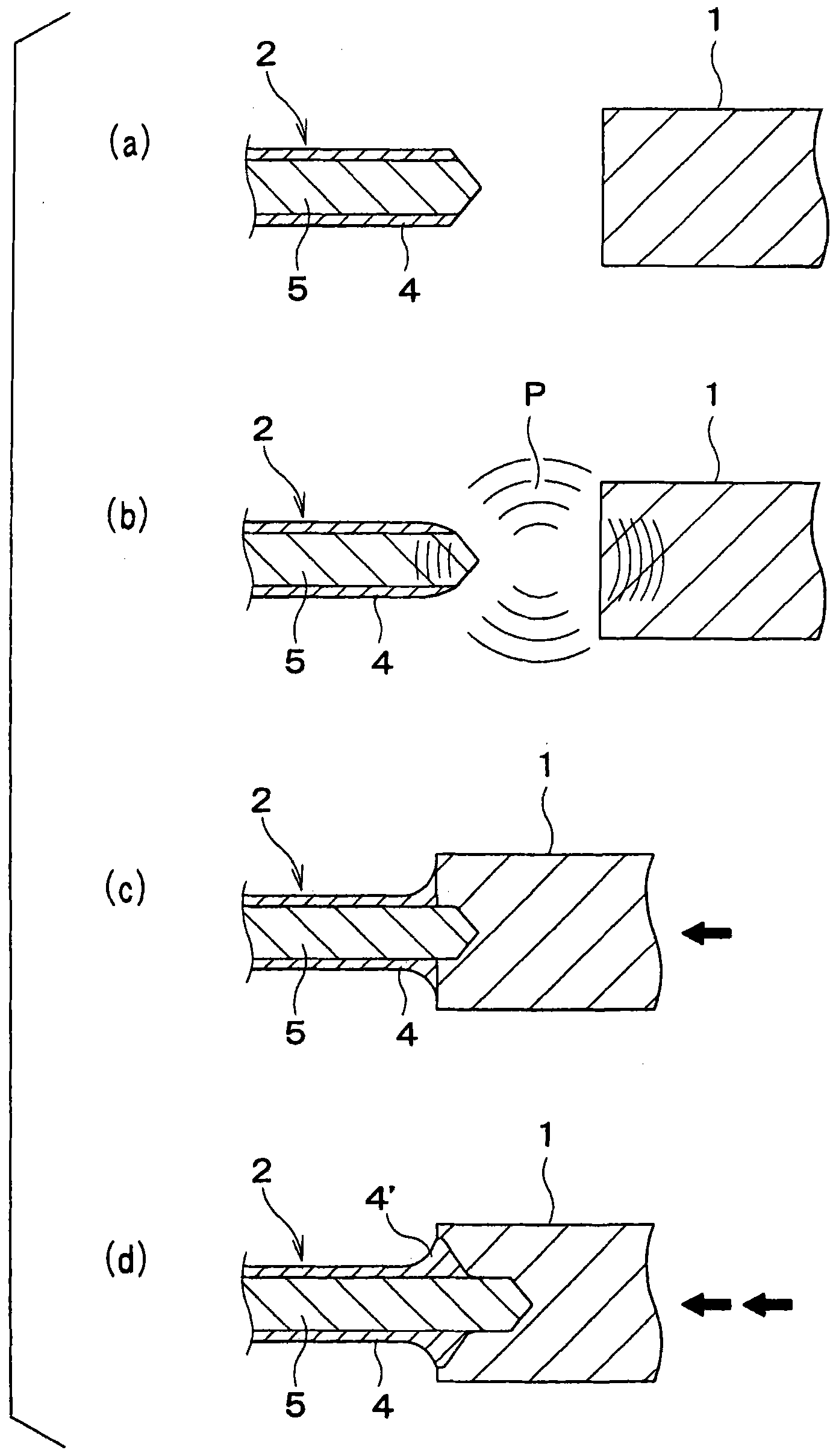

[0051] The copper lead wire and the aluminum wire cut into predetermined lengths are respectively held on respective electrodes of the impact welding device. Then, using a halogen lamp heater (IHU-A: manufactured by USHIO Electric Co., Ltd.), the irradiated light was condensed through a lens, and irradiated onto the aluminum electrode side tip portion of the lead member. When the temperature of the tip portion of the lead member was measured with a non-contact thermometer, the temperature was 260°C.

[0052] Then, in this state, a voltage (approximately 50 V) was applied to both electrodes to cause plasma discharge, and welding was pe...

Embodiment 2

[0054] As the lead terminal member, a 1.0 mmφ copper lead wire to which lead-free tin plating (plating thickness: 12 μm) was applied was used. The copper lead was cut to a length of 10.0 mm, and one end portion was processed into a 60° conical shape (taper processing). In addition, in the sealing plate member in which the aluminum base material is tightly fitted into the resin by integral molding, the welded surface of the aluminum base material is smoothed by pressing. These copper leads and the sealing plate member were respectively used as respective base materials of the impact welding device.

[0055] Next, in this state, a voltage (approximately 50 V) is applied to both electrodes to cause plasma discharge, and the tapered end of the copper lead wire is pressed against the core of the sealing plate member, and welding is performed. The copper lead was joined to the sealing plate member to obtain a sealing plate lead terminal for capacitors.

Embodiment 3

[0057] A lead terminal was obtained in the same manner as in Example 2, except that one tip portion of the copper lead in Example 2 was processed into a wedge shape with a tip angle of 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com