Underwater object lifting device

A hoisting and hoisting technology, which is used in underwater operation equipment, transportation and packaging, and vessel salvage, etc., can solve problems such as operation failure, hoisting failure, and being easily affected by sea conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

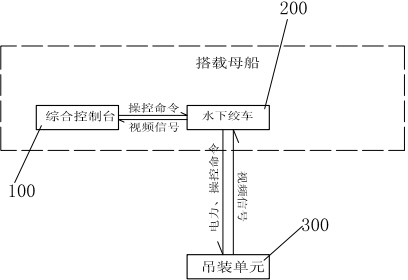

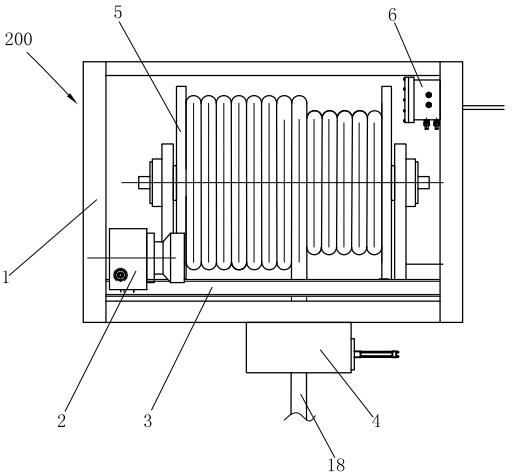

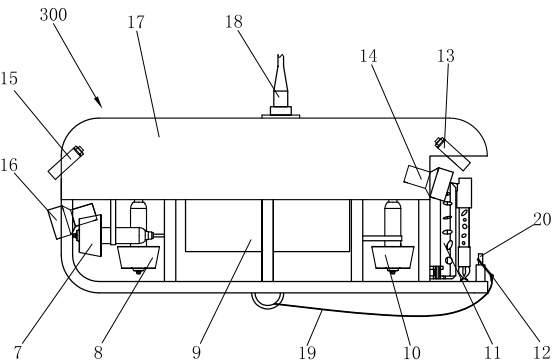

[0019] Such as figure 1 , 2 , 3, the present invention comprises integrated console 100, underwater winch 200 and hoisting unit 300, integrated console 100 and underwater winch 200 are connected by watertight cables, between underwater winch 200 and hoisting unit 300 through armored cables 18, the armored cable 18 can bear the weight of the hoisting unit 300 and the lifting object, and at the same time provide power support for the hoisting unit 300 and transmit the control signal sent by the integrated console 100. In the present invention, a submarine or an underwater mobile workstation is used as a mother ship, and the integrated control console 100 is arranged in the dry working cabin of the mother ship. The integrated console 100 includes a winch status monitoring module, a hoisting unit image display module, a win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com