High temperature-keeping screw conveyor

A screw conveyor and high-temperature technology, which is applied in the field of high-temperature bulk material conveying and blanking control, can solve the problems of inability to convey, blanking and heat preservation, etc., achieve improved service life, good strength and wear resistance, and solve timing and quantitative The effect of conveying blanking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

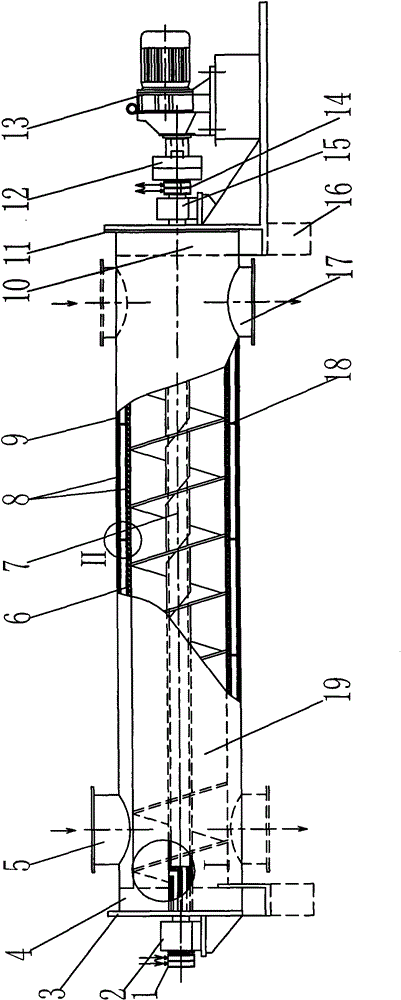

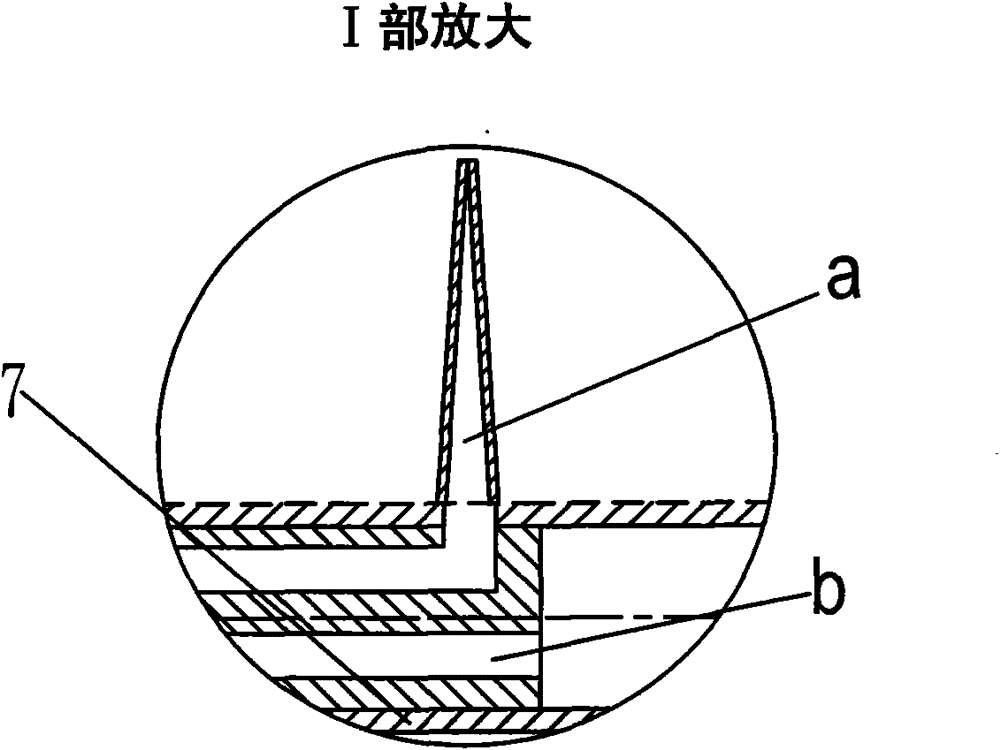

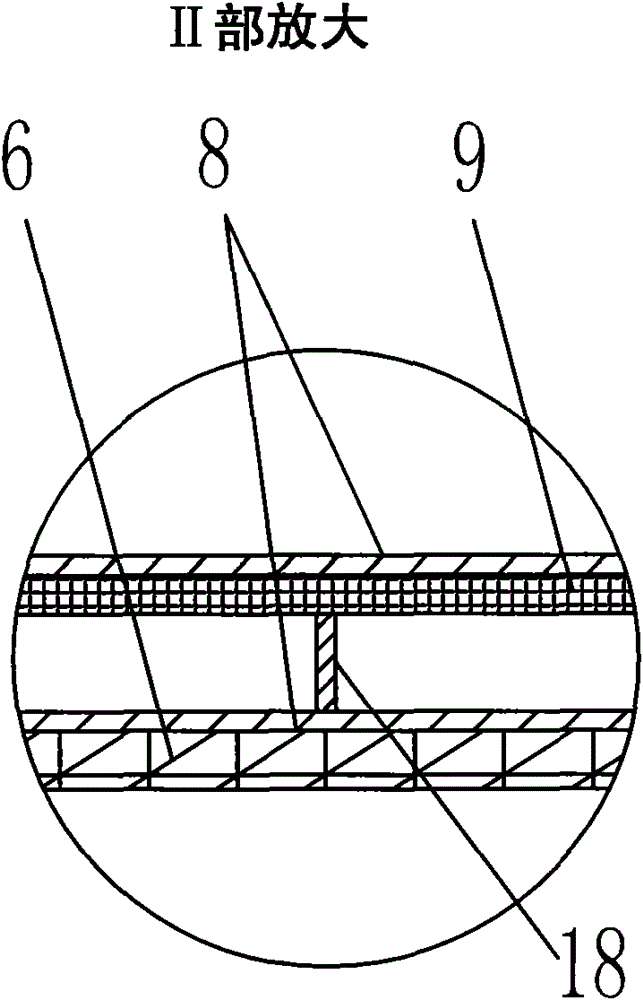

[0014] figure 1 , figure 2 and image 3 It is an embodiment disclosed by the invention. The front part of the cylindrical casing 19 of the high-temperature heat preservation screw conveyor is provided with a feed inlet 5, and the rear part of the cylindrical casing 19 is provided with a discharge port 17. The cylindrical casing 19 The weighing module 16 is arranged at the bottom of the cylinder, and the auger 7 is arranged in the cylindrical casing 19 . The cylindrical casing 19 is composed of a bushing 6 and two layers of stainless steel chambers 8, the bushing 6 is made of high temperature and wear-resistant metal material, and the outside of the bushing 6 is two layers of high temperature resistant stainless steel chambers 8 The two layers of stainless steel cylinder chambers 8 are connected by ring-shaped support partitions 18, the layer near the bushing 6 is an air layer, and the layer near the cylindrical casing 19 is an insulating layer 9 filled with aluminum silicat...

Embodiment 2

[0019] figure 1 , image 3 and Figure 4 It is another embodiment disclosed by the present invention. The structure of the high-temperature heat preservation screw conveyor is basically the same as that of Embodiment 1, the difference is that the feed inlet 5 is arranged at the rear of the cylindrical casing 19, and the outlet 17 is arranged At the front of the cylindrical casing 19 (see figure 1 Feed inlet, dotted line position of discharge outlet), the central axis of auger 7 in the cylindrical casing 19 is provided with cooling channel c, and the blade is a solid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com