Steel ladle

A ladle and cover technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems affecting the health of operators, air pollution, heat preservation effect limitations, etc., to achieve good health and improve Insulation effect, effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

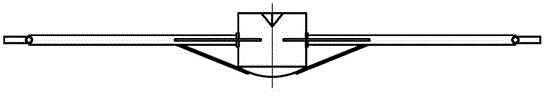

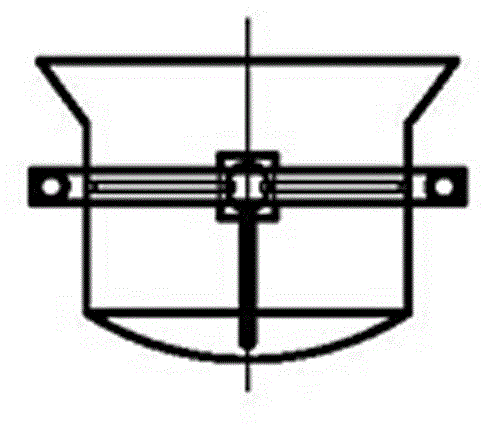

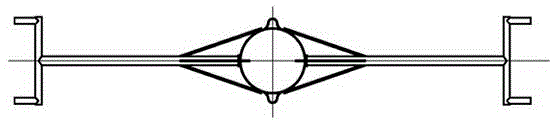

[0016] Such as Figure 1-3 As shown, a steel ladle includes a shell, a ladle, and a ladle, and a ladle is provided on the ladle.

[0017] Preferably, an insulation layer is provided between the mouth edge and the cover.

[0018] Preferably, the insulation layer is fixedly connected with the cover.

[0019] Preferably, an opening is opened on the ladle cover to communicate with the inner chamber of the ladle.

[0020] Preferably, the spout communicates with the inner chamber of the ladle through a through hole.

[0021] Preferably, the insulation layer is insulation cotton.

[0022] In this specification, the invention has been described with reference to specific embodiments thereof. However, it is obvious that various modifications and changes can be made without departing from the spirit and scope of the invention. Accordingly, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com