Fiber fabric extraction box for glass fiber reinforced plastic hand lay-up molding

A technology of hand lay-up and fiber fabric, which is applied in the field of fiber fabric extraction box for FRP hand lay-up, which can solve the problems of affecting construction efficiency, reducing the quality of the mixture, and slow production speed, so as to achieve thickness and surface smoothness, and improve production Speed, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

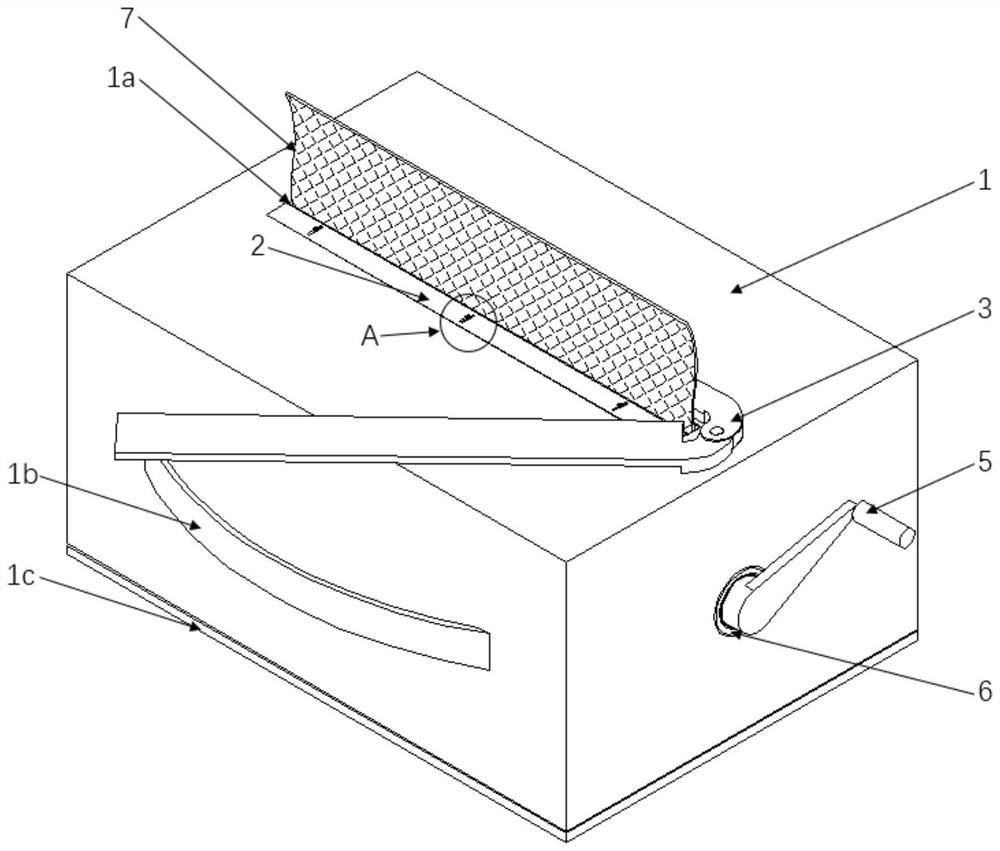

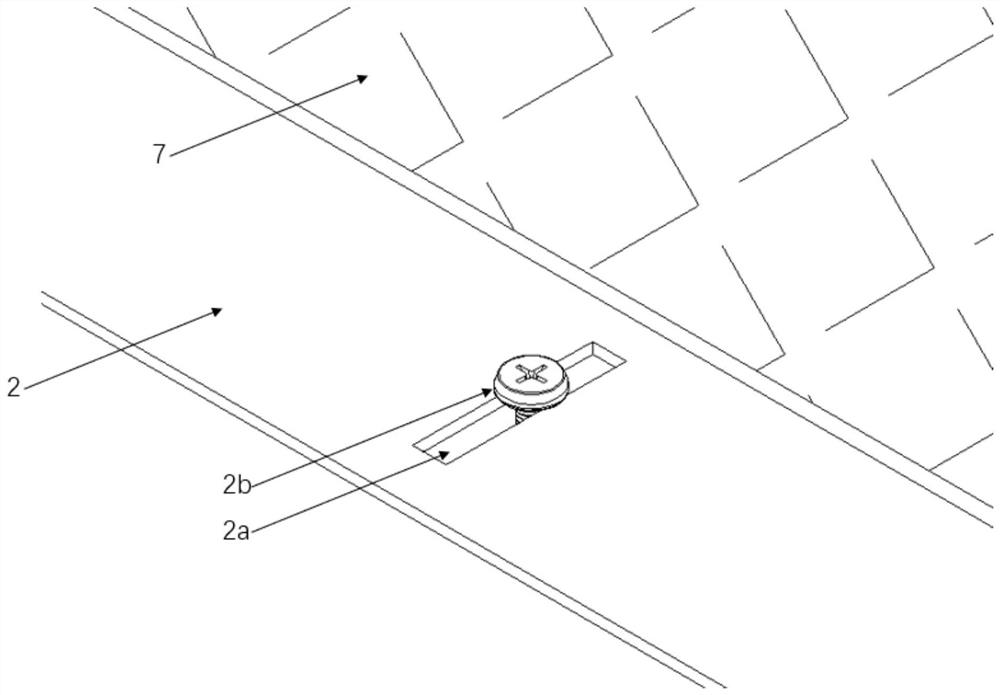

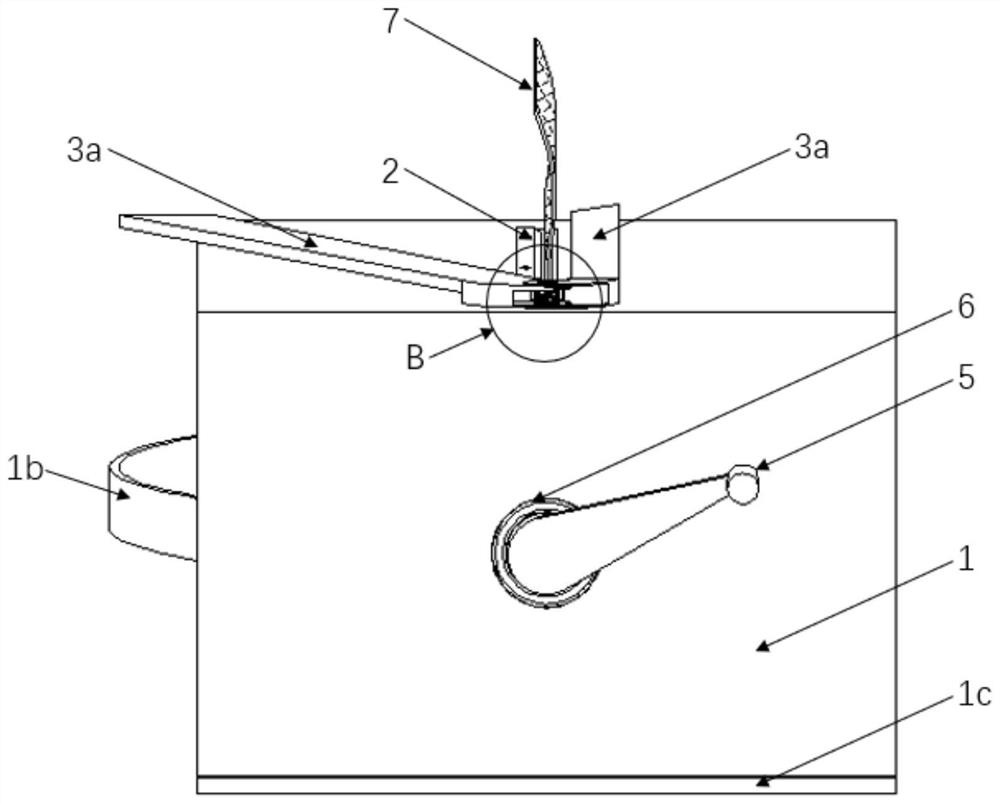

[0029] Such as Figure 1~Figure 10 As shown, the fiber fabric extraction box for FRP hand lay-up molding includes a box body 1 with a hollow structure. The bottom of the box body 1 is provided with an openable bottom cover 1c. The bottom cover 1c is provided for injecting into the box body 1 after opening The resin mixture 8 and the glass fiber fabric 7 are packed inside the box body 1; the upper part of the box body 1 is provided with a discharge notch 1a, and the discharge notch 1a is provided with a scraper 2, and the glass fiber fabric 7 is adhered in the box body 1 After the resin mixture 8 is applied, it comes out from here, passing through the gap between the scraper 2 and the discharge slot 1a, the scraper 2 scrapes off the excess adhesive material to make the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com