Lubrication structure of connecting rod large-head roller pin for dune buggy engine

A technology of engine connecting rod and lubricating structure, applied in the direction of engine lubrication, engine components, machine/engine, etc., can solve the ablation of small side cover bushing hole, oil hole blockage, engine connecting rod big end needle roller ablation, etc. The problem is to prevent the lack of oil on the connecting rod big end needle roller, increase the lubrication reliability, and prevent the engine connecting rod big end needle roller from running out of oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

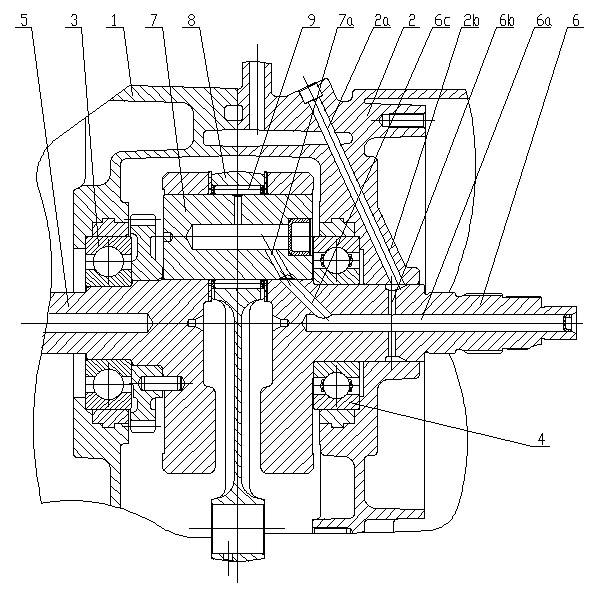

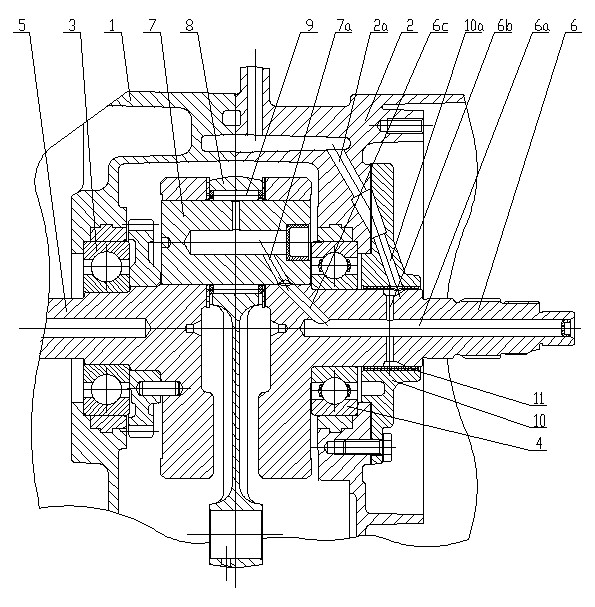

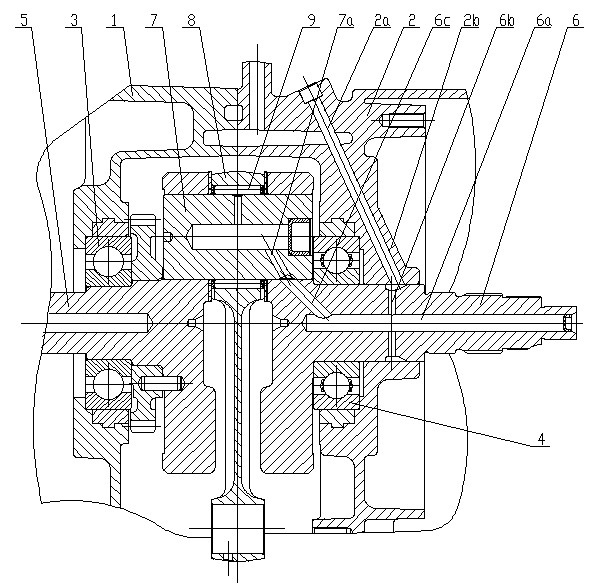

[0011] like figure 1 As shown, the present invention is made of left crankcase 1, right crankcase 2, first bearing 3, second bearing 4, left crankshaft 5, right crankshaft 6, crankpin 7, connecting rod 8 and needle roller 9, wherein the left crankshaft Case 1 and right crankcase 2 are connected and fixed by positioning pins and bolts to form a crankcase body. The crankcase 1 is provided with a bearing hole, and the first bearing 3 is press-fitted in the bearing hole, and the first bearing 3 is supported with the left crankshaft 5 . Also be provided with bearing hole on right crankcase 2, press-fit second bearing 4 in this bearing hole, second bearing 4 and right crankshaft 6 phase supports. Described left crankshaft 5 and right crankshaft 6 are connected with the big end of connecting rod 8 by crank pin 7, and needle roller 9 is housed between the big end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com