Structure for improving cooling efficiency of gas film of discrete hole

A film cooling, discrete hole technology, applied in the cooling of the engine, the cooling of the turbine/propulsion device, the supporting element of the blade, etc., can solve the problems of low cooling efficiency, decreased cooling efficiency, etc., and achieve a simple and convex structure. Small size, great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

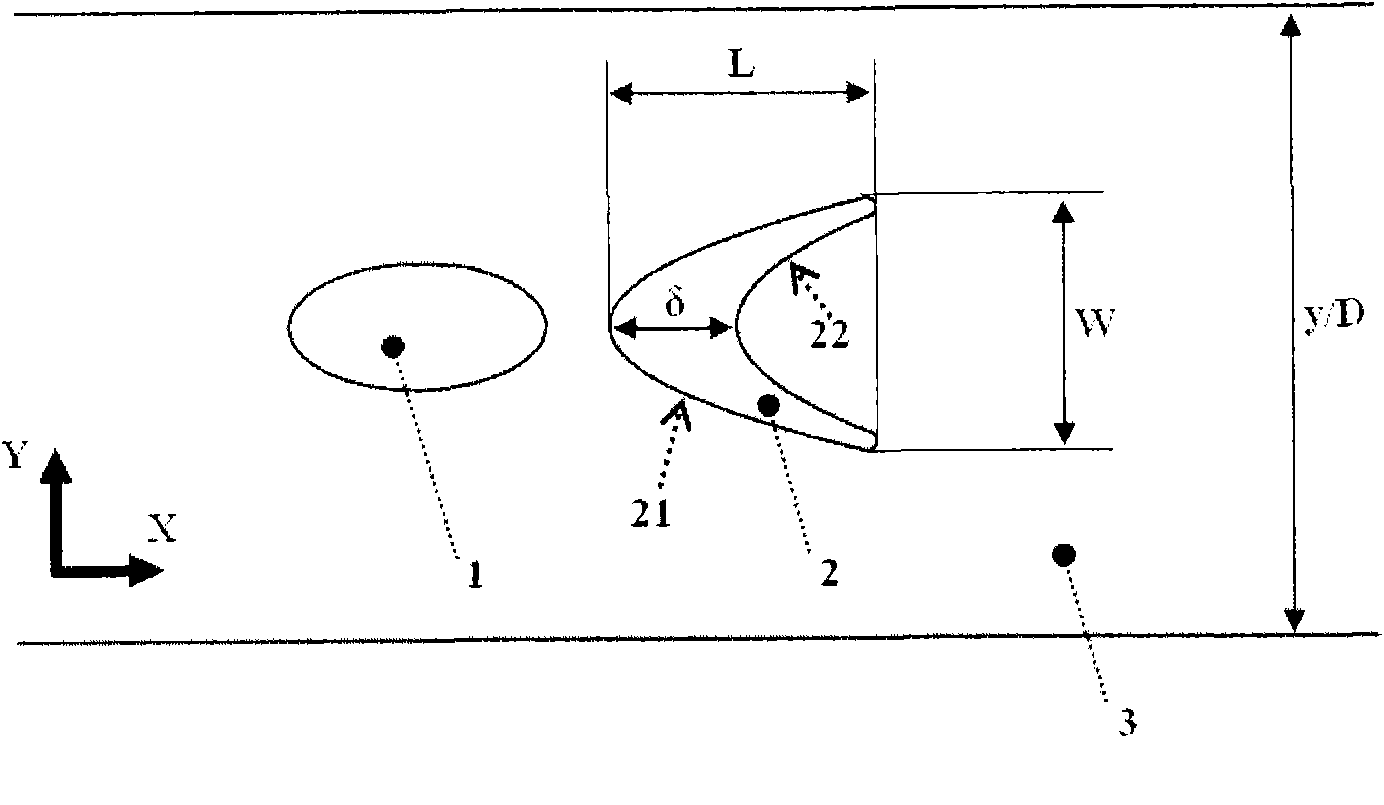

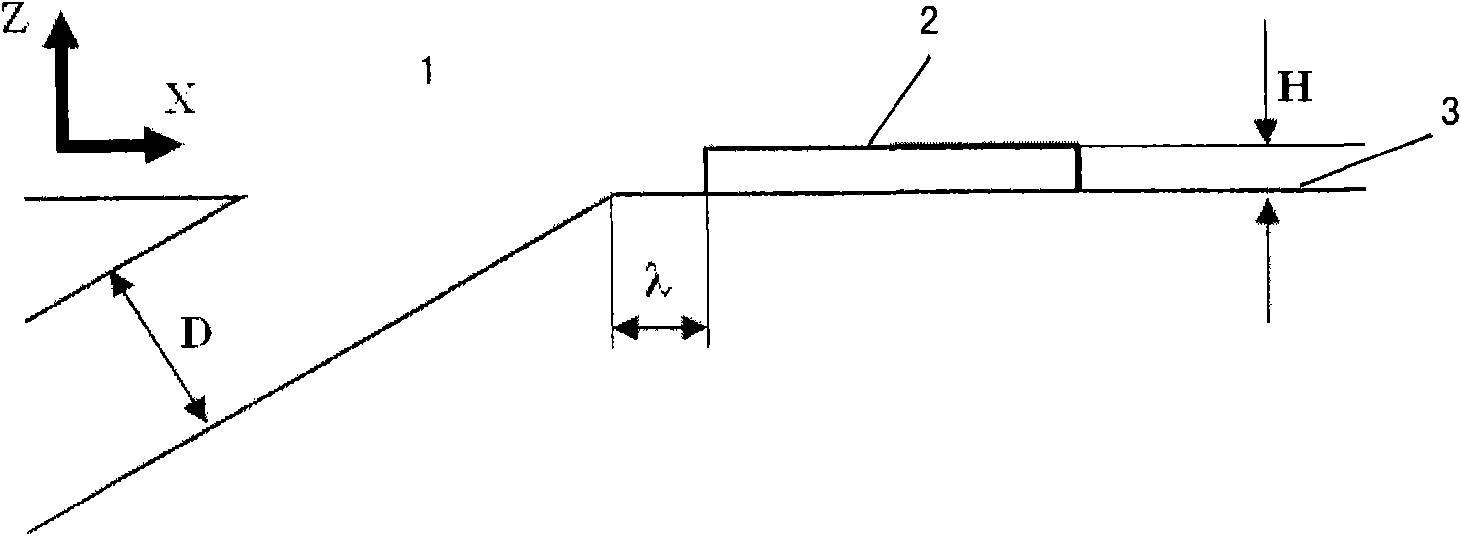

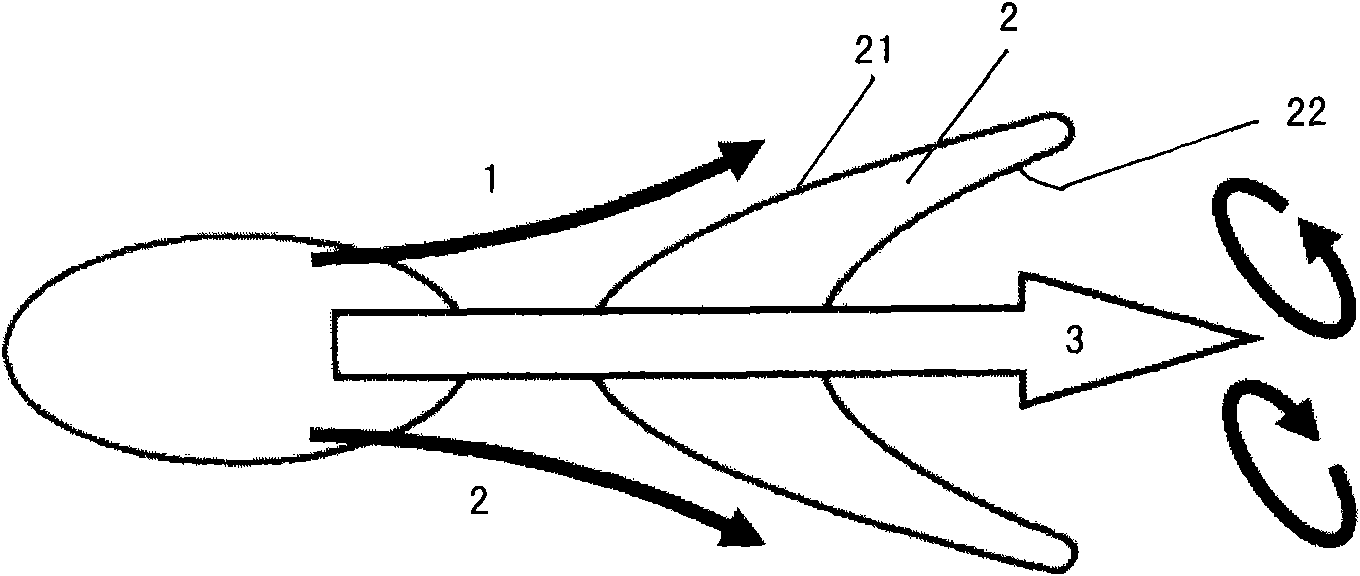

[0034] As shown in FIG. 1 , it is a schematic structural diagram of improving the efficiency of film cooling of discrete holes according to the present invention, wherein, film holes 1 , protrusions 2 , and surfaces 3 . It is defined by the structural parameters of the crescent-shaped protrusion 2 downstream of the air film hole 1 shown in FIG. 1 . The length, width and height of the protrusion 2 are represented by L, W and H respectively. The diameter of air film hole 1 is represented by D. Several main flow directions are shown by coordinates X, Y, and Z respectively, where X is the flow direction, Y is the transverse direction, and Z is the radial direction. The flow distance between the protrusion 2 and the air outlet side of the air film hole 1 is represented by λ. The maximum thickness of the protrusion 2 is indicated by δ. In addition, the profile line of the protrusion 2 along the upstream side is defined as the intake side line 21 of the protrusion 2 , and the prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com