Guide wheel outline detection method and system

A contour detection and guide wheel technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of large size, inability to accurately give contour maps and dimensions, inaccurate detection results, etc., and achieve the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

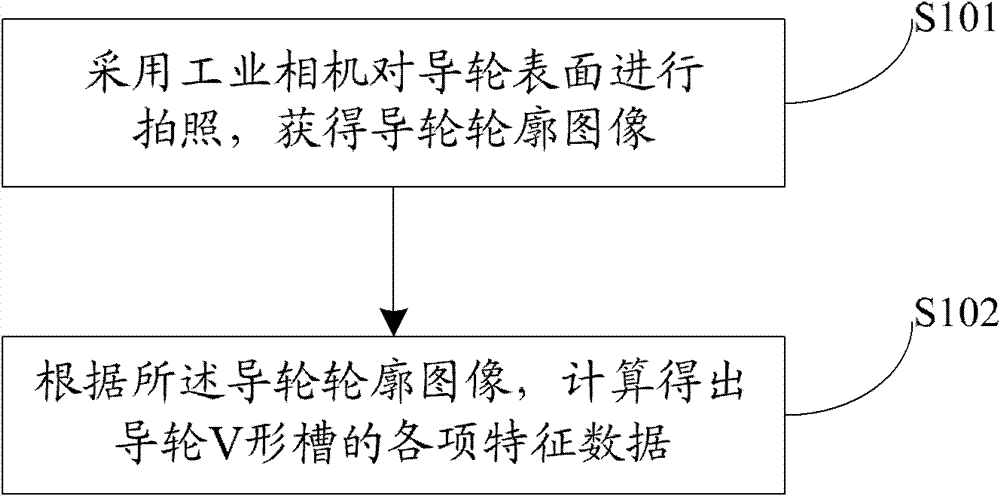

[0061] The flow chart of the guide wheel profile detection method disclosed in this embodiment is as follows: figure 1 shown, including the following steps:

[0062] Step S101: using an industrial camera to take pictures of the surface of the guide wheel to obtain a contour image of the guide wheel;

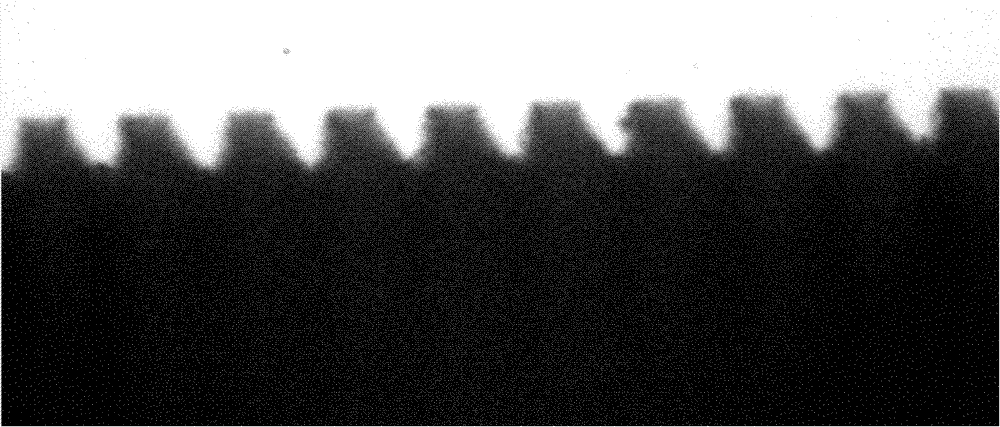

[0063] It should be noted that there are many tools used to obtain the profile image of the guide wheel. In this embodiment, only the industrial camera is used as an example for illustration. Due to the high resolution of the industrial camera, the image of the profile image of the guide wheel is more accurate. Accurate, the profile image of the guide wheel obtained by photographing in this embodiment is as follows figure 2 shown, from figure 2 It can be seen from the figure that the outline image of the guide wheel is clear, and the actual situation of the V-shaped groove on the surface of the guide wheel can be accurately judged.

[0064] Step S102: According to the profile ...

Embodiment 2

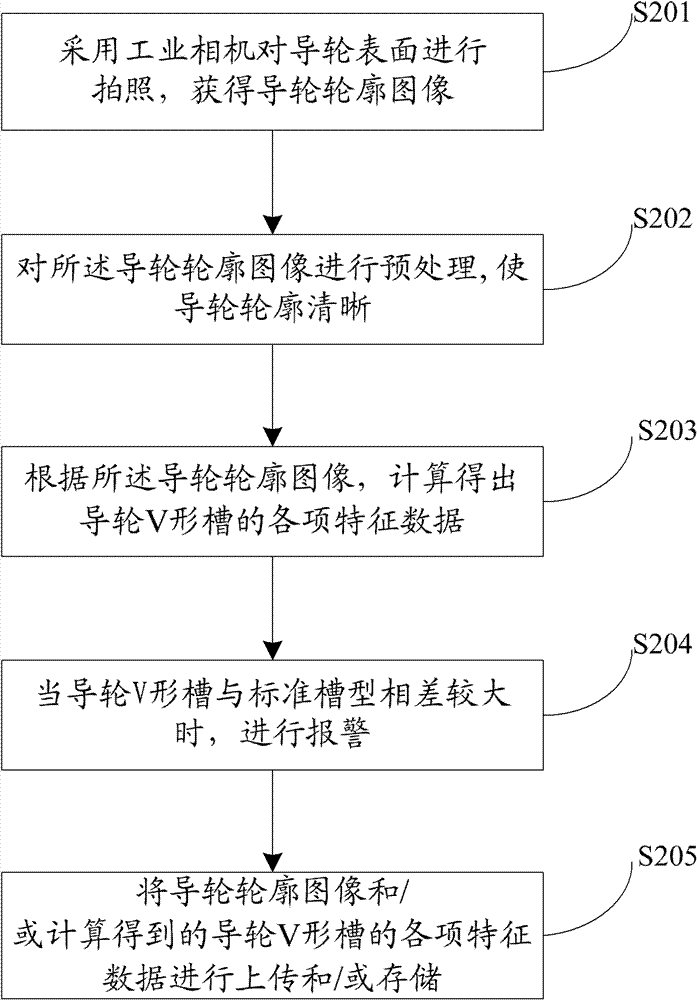

[0067] The flow chart of the guide wheel profile detection method disclosed in this embodiment is as follows: image 3 shown, including the following steps:

[0068] Step S201: using an industrial camera to take pictures of the surface of the guide wheel to obtain a contour image of the guide wheel;

[0069] Step S202: Perform preprocessing on the outline image of the guide wheel, such as sharpening, increasing contrast, etc., to make the outline of the guide wheel clear, so as to facilitate subsequent calculation of various characteristic data of the V-shaped groove;

[0070] It should be noted that the preprocessing of the guide wheel profile image is only an optional step, and if the guide wheel profile image obtained in step S201 is clear enough, no preprocessing is required.

[0071] Step S203: According to the contour image of the guide wheel, calculate and obtain the characteristic data of the V-shaped groove of the guide wheel, and the characteristic data of the V-sha...

Embodiment 3

[0102] The embodiment of the invention discloses a guide wheel profile detection system, its structure diagram is as follows Figure 9 As shown, the system includes:

[0103] A guide wheel profile detection device 101, configured to obtain a guide wheel profile image;

[0104] A processing module connected to the guide wheel profile detection device, the processing module comprising:

[0105] The visual interface 102 enables the operator to observe the outline of the guide wheel in time;

[0106] The data processing unit 103 is used to calculate various feature data of the V-shaped groove of the guide wheel according to the outline image of the guide wheel, and the various feature data of the V-shaped groove include groove angle, groove height and groove distance.

[0107] Additionally, the system includes:

[0108] The alarm unit 108 is used for when the difference between the guide wheel profile and the standard profile exceeds the preset standard, and / or when the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com