Riser stress measuring device and measuring method

A technology of stress measurement and measurement device, which is applied in the direction of measuring force by measuring the change of optical properties of materials when they are stressed, and can solve the problems of high sensitivity, easy damage to the anti-corrosion coating of the riser, and reduced accuracy of the measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

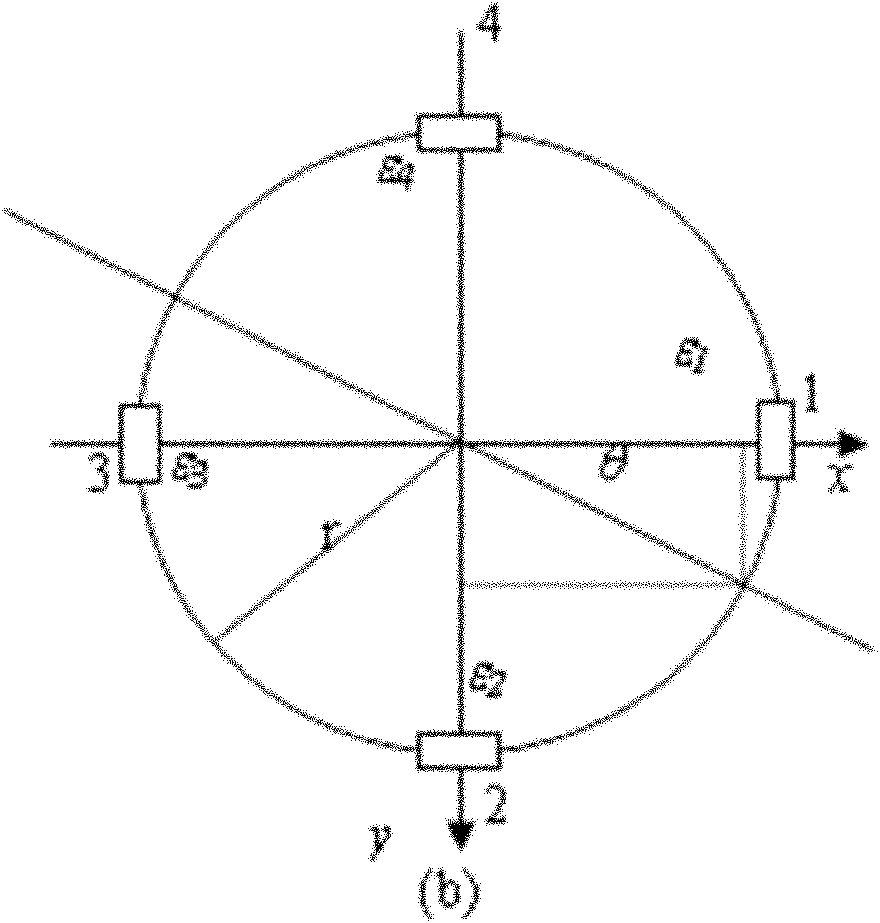

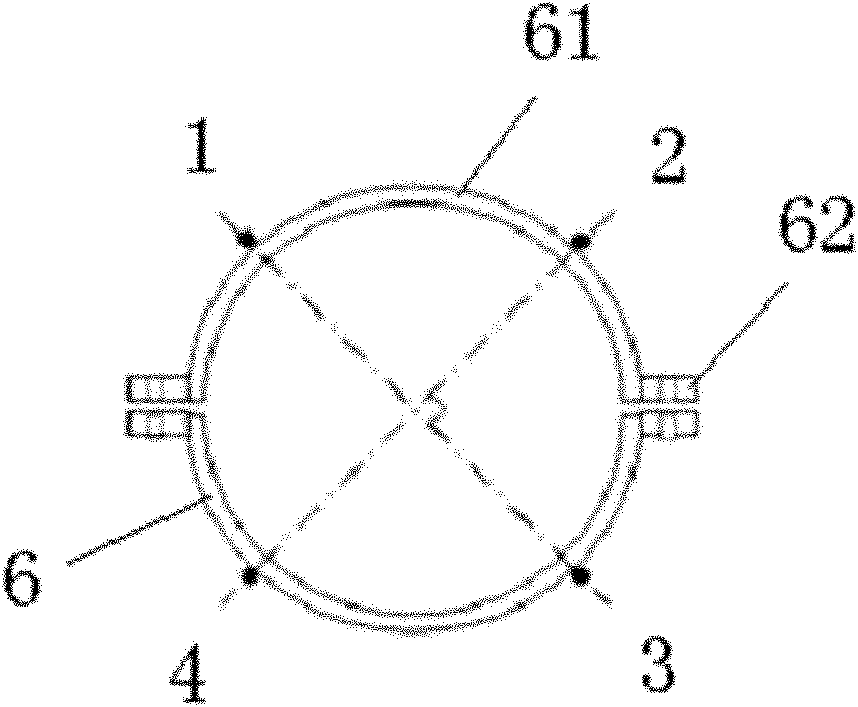

[0035] Such as image 3 , Figure 4 As shown, the present embodiment includes a cable tie 6, and the cable tie 6 includes two semi-circular rings 61 symmetrically arranged, and a connection plate 62 is respectively provided at the joint at both ends of each semi-circular ring 61, and the two semi-circular rings 61 correspond to The two pairs of connection plates 62 are fixedly connected into one body by bolts. The combined inner diameter of the two semicircular rings 61 is slightly smaller than the outer diameter of the riser, so as to ensure that the combined inner diameter and the outer diameter of the riser 5 can fit together closely. The four sensors 1 , 2 , 3 , 4 are respectively fixed on the cable tie 6 at 45° to their adjacent connecting pads 62 , and are located on the same circumference.

Embodiment 2

[0037] Such as Figure 5 , Image 6 As shown, this embodiment includes two cable ties 7 arranged in parallel, and each cable tie 7 includes four quarter rings 71, and the joints at both ends of each quarter ring 71 are respectively provided with a connection The discs 72 and the corresponding four pairs of connecting discs 72 on the four quarter rings 71 are fixedly connected into one body by bolts. The combined inner diameter of the four quarter rings 71 on each cable tie 7 is slightly smaller than the outer diameter of the riser 5 to ensure that the combined inner diameter and the outer diameter of the riser 5 can fit together tightly . A T-shaped beam 73 is oppositely arranged at the midpoint of every two quarter rings 71 arranged in parallel, and a sensor 1, 2, 3, 4 (sensor 4) is respectively arranged between four pairs of opposite T-shaped beams 73 bottom ends. Not visible in the figure), the four sensors 1, 2, 3, 4 are located on the same circumference.

[0038] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com