Method for processing battery pole pieces and labo waste collecting device

A processing method and battery pole piece technology, which is applied in the field of battery pole piece processing and Labo waste collection device, can solve the problems of increased machine cost and operating cost, increased power, increased number of control points, etc., and achieves low equipment cost and easy operation. Convenience and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

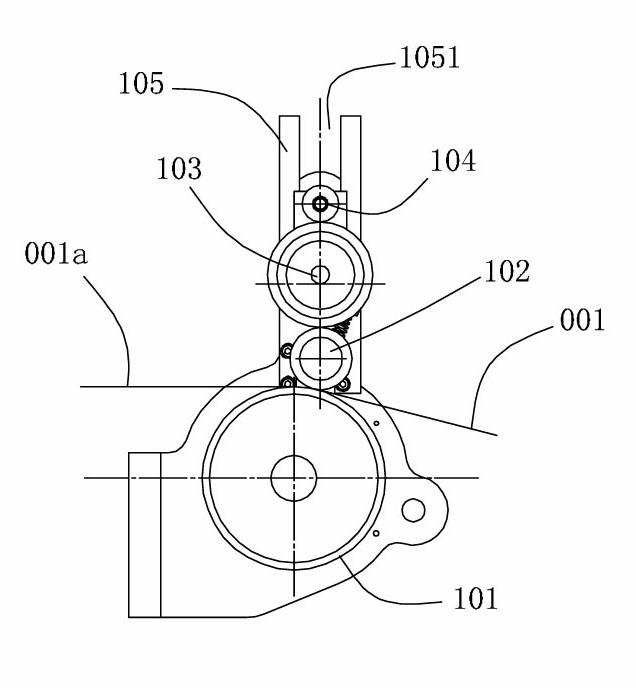

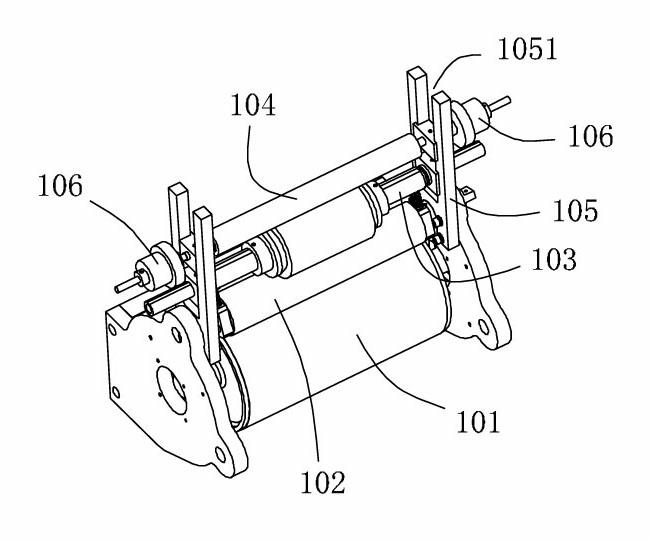

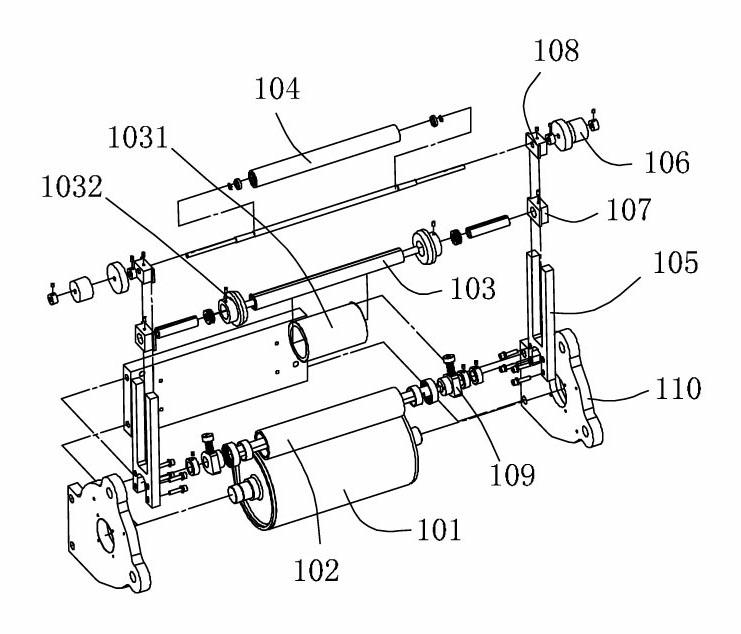

[0025] refer to figure 1 , figure 2 , image 3 , the first embodiment of the present invention is a pull wave waste collection device, including a pull wave 101 and a pressing rubber roller 102, a waste collection roller 103 is arranged above the pressing rubber roller 102, and a pair of supporting walls oppositely arranged 105, the support wall 105 has an upward opening 1051, the two ends of the waste collection roller 103 are set on the opening 1051 through the slider 107, and the surface of the waste collection roller 103 abuts against the surface of the pressing rubber roller 102 by gravity . The smoothing roller 104 is disposed on the opening 1051 through the slider 108 , and the smoothing roller 104 abuts against the surface of the waste collection roller 103 through gravity. Both ends of the smoothing roller 104 are provided with counterweights 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com