V-shaped slot rotor of self-starting permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and V-groove, which is applied in the direction of synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve the problem of increasing eddy current loss of permanent magnets, squirrel cages and iron cores, Problems such as poor mechanical stress of the rotor silicon steel sheet and irreversible loss of magnetism of the permanent magnet can avoid local loss of magnetism, optimize the magnetic circuit, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

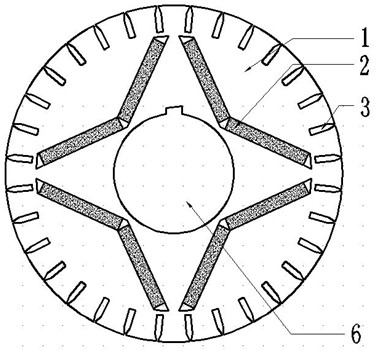

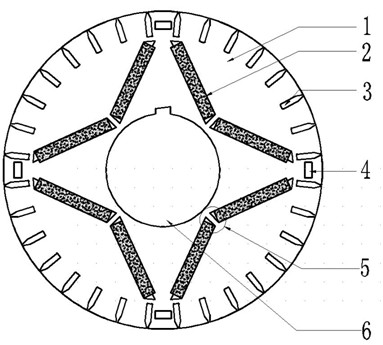

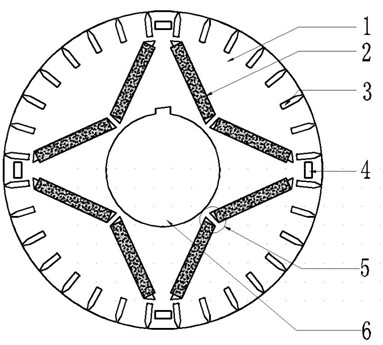

[0028] refer to figure 2 The self-starting permanent magnet synchronous motor V-groove rotor includes iron core 1, permanent magnet 2, squirrel cage guide bar 3 and shaft 6. The iron core has grooves arranged in a V shape, and every two permanent magnets placed in the V-shaped groove constitute One magnetic pole, the illustrated example has 4 magnetic poles, the bottom of each V-shaped groove is separated, forming a magnetic bridge of two permanent magnets in the V-shaped groove, and two squirrel cage guide bars corresponding to the top of the adjacent V-shaped groove 3 Axial air grooves 4 are arranged between them.

[0029] The V-groove rotor of the self-starting permanent magnet synchronous motor of the present invention can also only use the bottom of each V-groove to separate each other to form a magnetic bridge of two permanent magnets in the V-groove. Or only the axial air grooves are arranged between the two squirrel cage guide bars corresponding to the tops of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com