Differential screw hole-making device and method

A hole-making device and differential screw technology, applied in automatic control devices, driving devices, feeding devices, etc., can solve the problems of heavy weight, low hole capacity without an axial feeding mechanism, and complex structure, and achieve a reduction in the size of the device. The effect of weight, improving work efficiency, and simplifying the composition of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The differential screw drilling device and method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

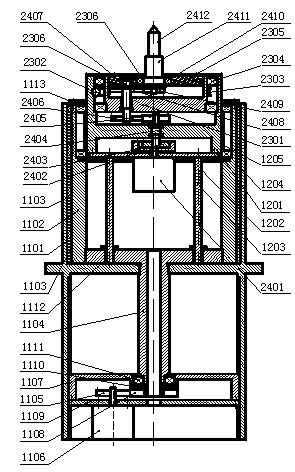

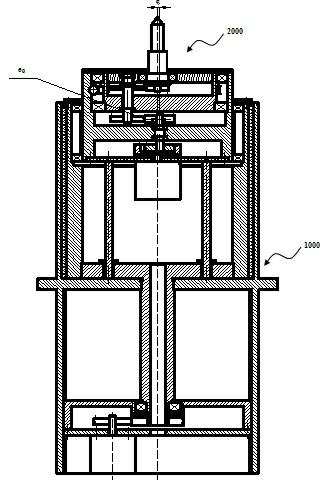

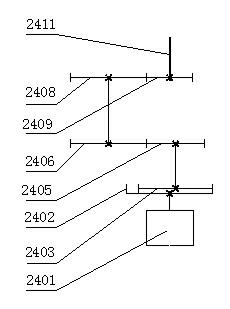

[0018] figure 1 It is a spiral hole-making device for difficult-to-machine materials disclosed by the present invention. The device mainly includes a support cylinder 1101 with a partition in the middle. The support cylinder is divided into an upper support cylinder and a lower support cylinder by the partition, and also includes a The screw feed mechanism 1000 used to realize the spiral movement of the cutter bar 2411 in the support cylinder, the self-rotation mechanism 2400 used to drive the cutter bar to rotate, and the radial deviation adjustment mechanism 2300 to adjust the offset of the cutter bar relative to the central axis of the support cylinder;

[0019] The screw feed mechanism 1000 is mainly composed of a first sliding cylinder 1102 with an internal thread, a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com