Sanding belt reciprocating and track correcting device of wide belt sander

A broadband sander, reciprocating motion technology, applied in abrasive belt grinders, grinding/polishing equipment, grinders, etc., can solve the problems of time-wasting correction, poor belt processing conditions, and difficult economic growth, etc., to reduce The effect of unilateral wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The structure, features and other objects of the present invention will be described in detail below in conjunction with preferred embodiments and accompanying drawings.

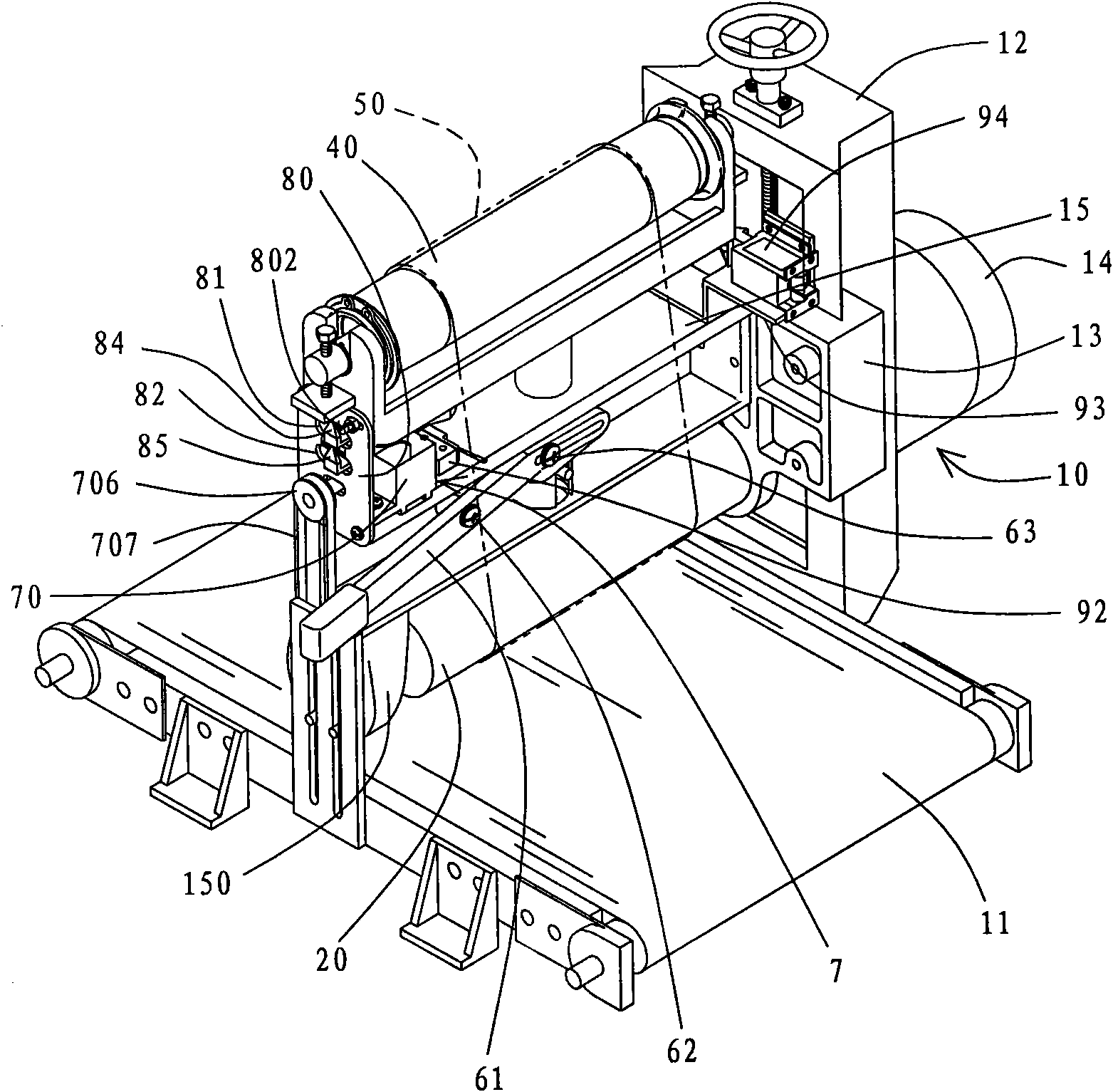

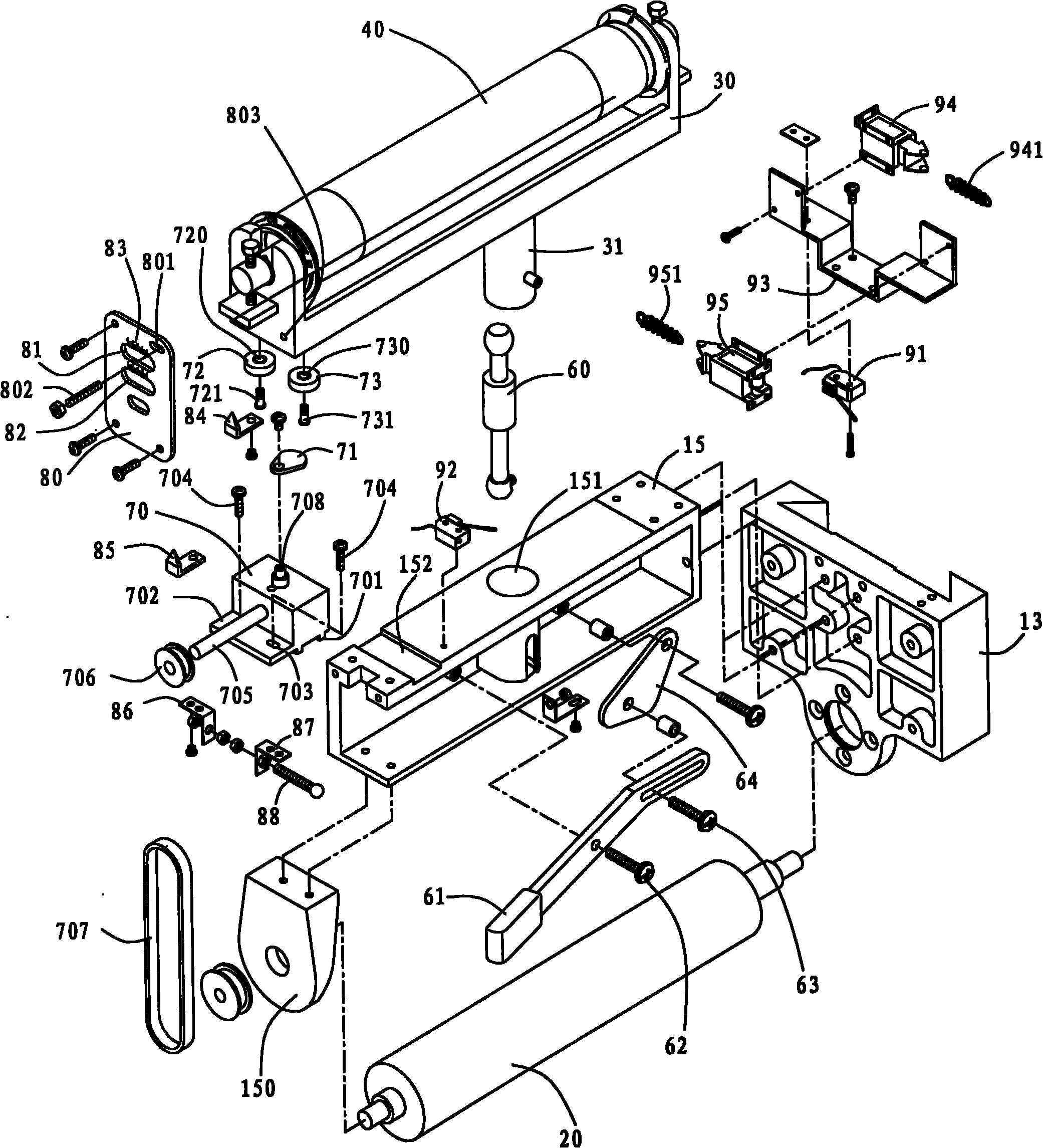

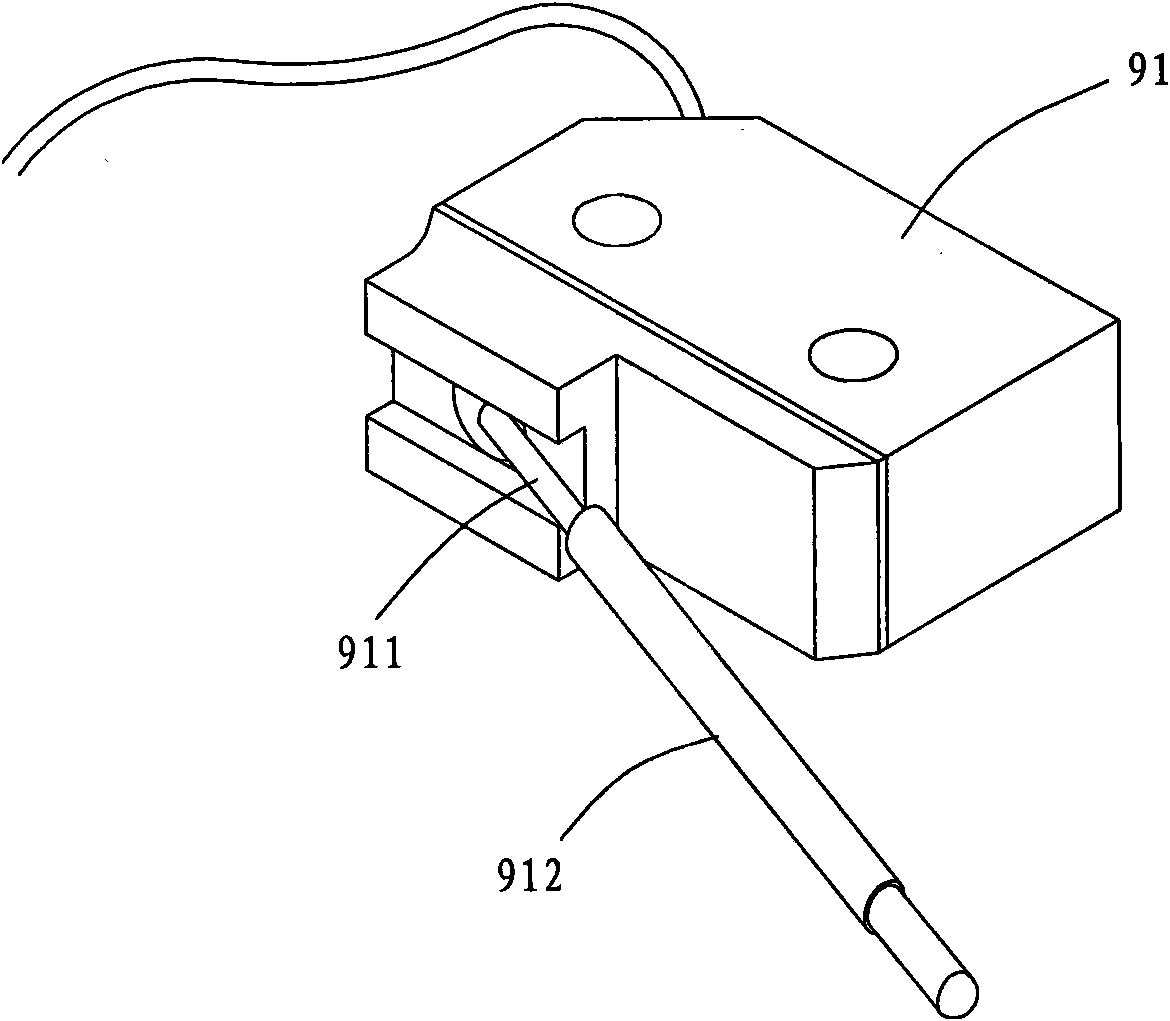

[0052] Please see figure 1 , figure 2 and Figure 4 , the present invention includes a machine base 10, a driving wheel 20 arranged horizontally, a bracket 30, a driven wheel 40, a straight-axis air pressure buffer rod 60, a correction configuration, an adjustment assembly and an electric control correction device .

[0053] There are at least two rollers on the horizontally spaced pivot at the bottom of the machine base 10, and the outer periphery of the aforementioned rollers is provided with an abrasive belt 11. Under the rotation of any roller, the abrasive belt 11 is rotated together, so that the horizontal working platform formed by the abrasive belt 11 can be Provide sanding on the bottom surface of the workpiece; the machine base 11 is vertically provided with a column 12 on the back side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com