Hobbing cutter slitting machine

A cutting machine and hob-type technology, which is applied in the field of hob-type cutting machines, can solve the problem of large loss of lining cloth and rubber pads on the surface of conveyor belts and transmission belts, affecting the appearance quality and production output of punched pieces, and easy parts. Loss and other issues, to achieve the effect of low maintenance cost, easy replacement and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

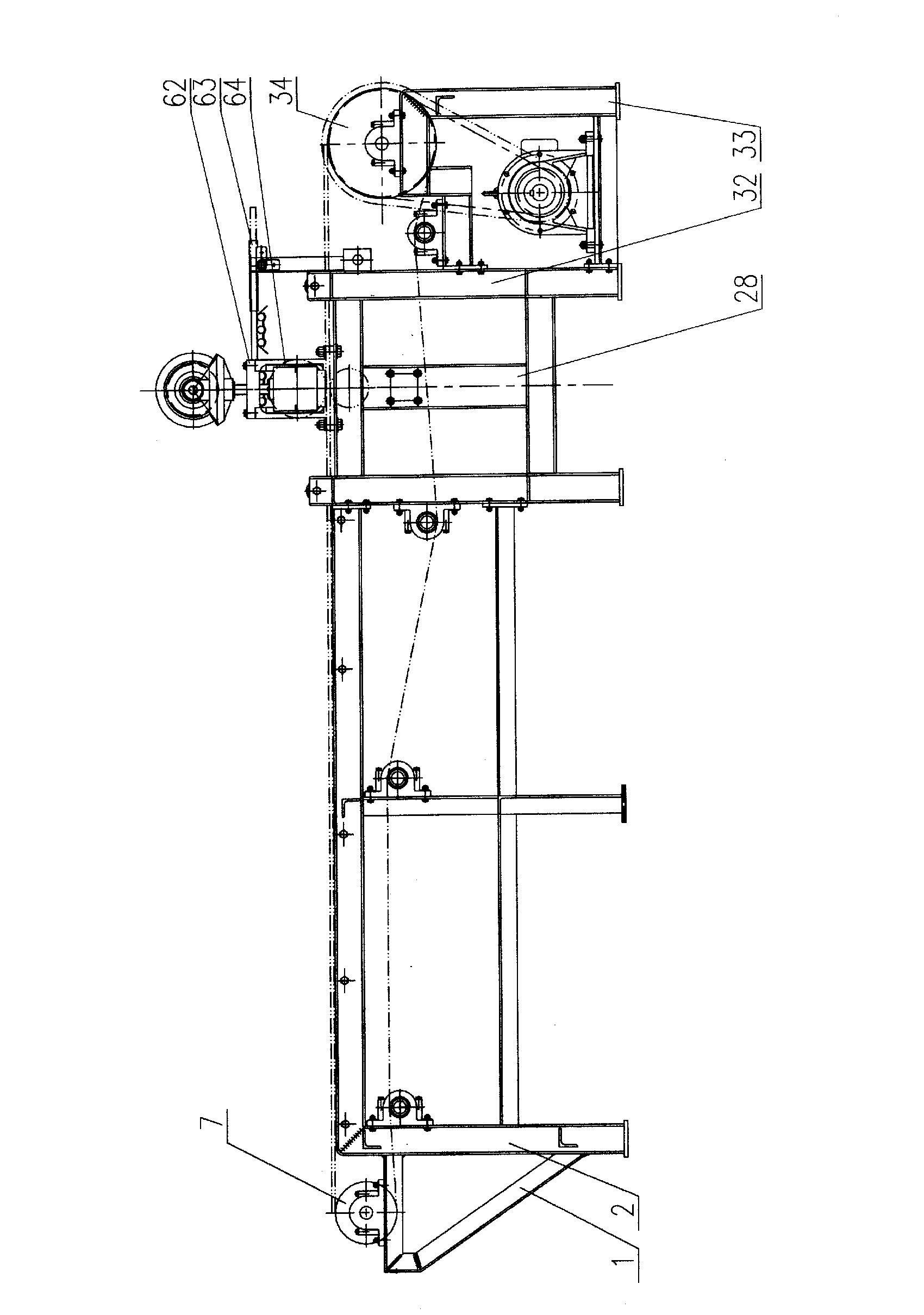

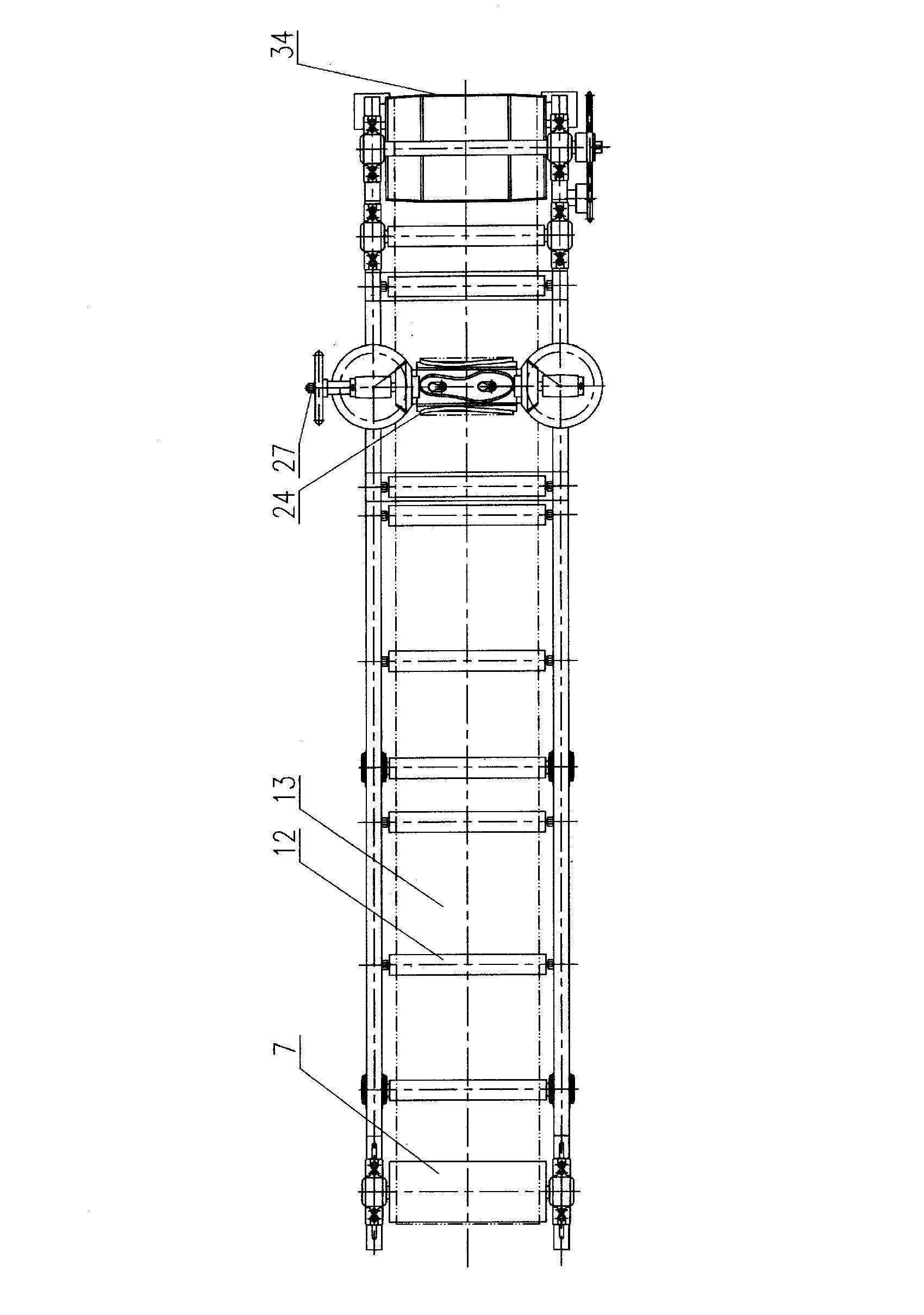

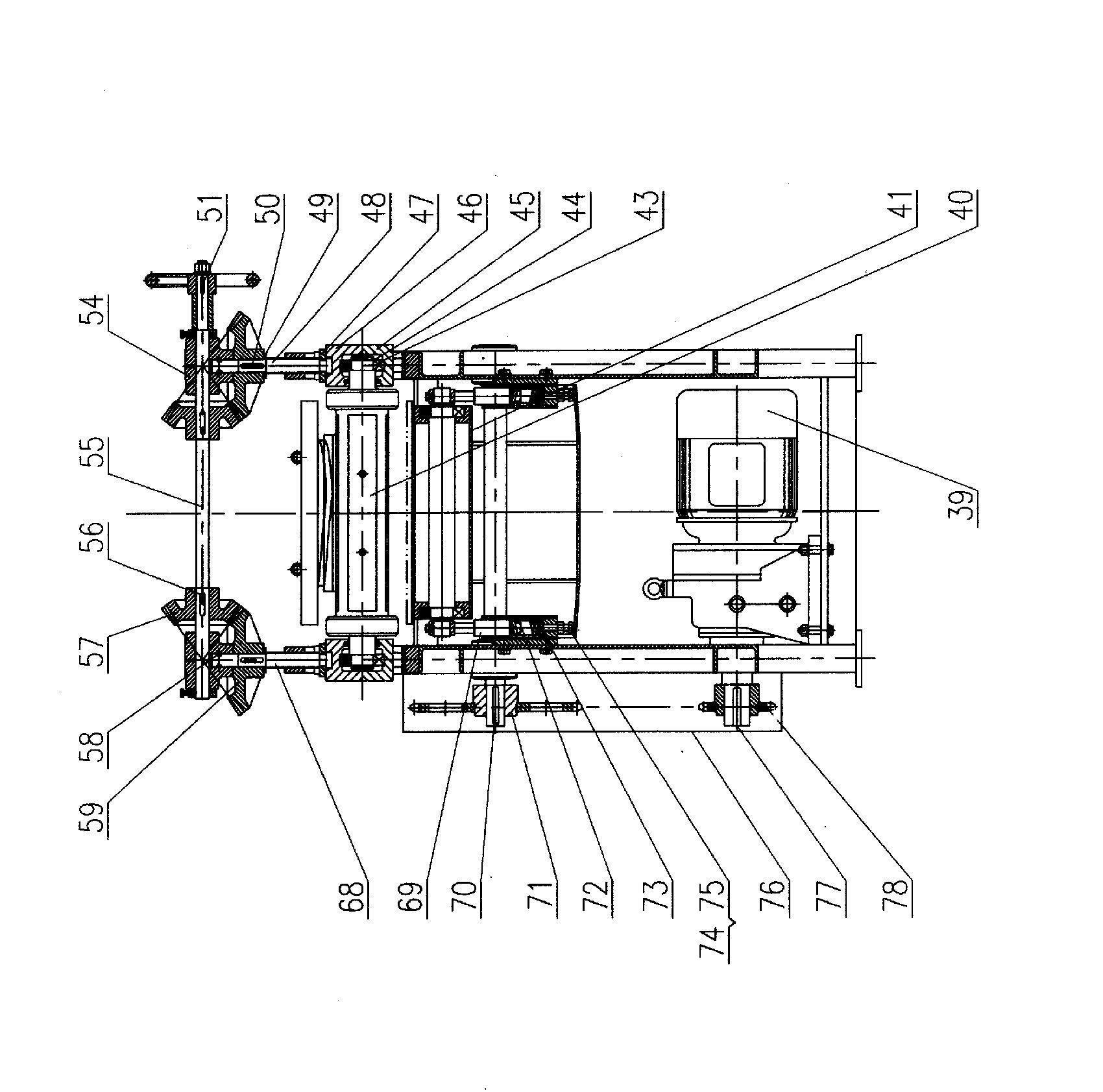

[0019] Depend on Figures 1 to 8 It can be seen that the present invention includes a bracket, a transmission device, a hob device, a hob support roller device and a heating device, wherein:

[0020] The bracket includes a driving roller bracket 33, a hob frame 32, a conveyor belt frame 2 and a driven roller bracket 1, and all frames are fixedly connected into one;

[0021] The transmission device includes a cycloidal pinwheel reducer 39, a driving roller 34, a driven roller 7 and a conveyor belt 13 connected between the driving roller 34 and the driven roller 7;

[0022] The hob device includes a hob 24, a hob seat shaft 40, a hob support roller 41 and a handwheel 27 for controlling and adjusting the hob 24;

[0023] The cycloidal pinwheel reducer 39 and the driving roller 34 are arranged on the driving roller frame 33, the hob device is arranged on the hob cutter frame 32, the driven roller 7 is arranged on the driven roller support 1, and the conveyor belt 13 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com