Temperature-sensitive hydrogel based on chemical cross-linking gel granules and preparation method of temperature-sensitive hydrogel

A temperature-sensitive hydrogel and chemical cross-linking technology, applied in the field of biomaterials and polymers, can solve problems such as limiting material applications and drug inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

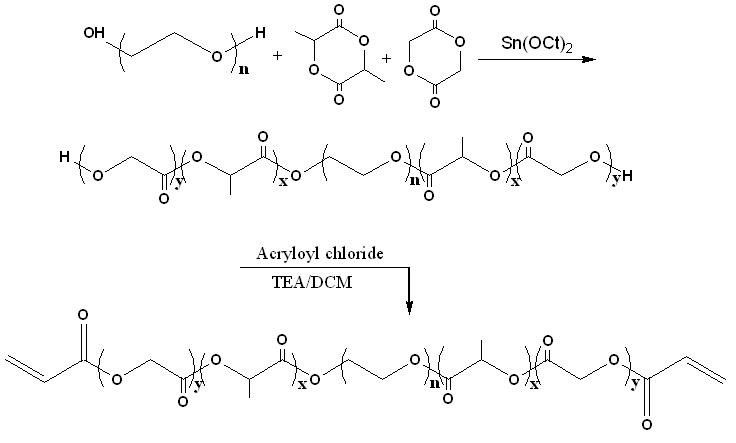

[0031] Example 1 Add 30g of dihydroxypolyethylene glycol (1500) into a 500ml three-necked flask, remove water under vacuum at 130°C for 4 hours, cool to 70°C with argon, add 50g of lactide, 10g of glycolide, and 26mg of octanoic acid For stannous (containing a small amount of toluene), vacuumize at 100°C for 30 minutes, flow argon, and raise the temperature to 130°C for 12 hours. After the reaction was completed, the product was poured out while it was hot. After cooling, the product was dissolved in dichloromethane and ether precipitated. Dissolve 15 g of the above block polymer in dichloromethane, slowly add acryloyl chloride (4 mL) in dichloromethane solution (50 mL) dropwise, and use triethylamine (4 mL) as an acid-binding agent, in an ice bath Add dropwise for 8 hours, then stir and react at room temperature for 48 hours. Precipitate with glacial ether and dry in vacuo to obtain the desired macromonomer. Synthesis schematic as figure 1 shown.

Embodiment 2

[0032] Example 2 Dissolve 1 g of the macromonomer obtained in Example 1 in 100 mL of deionized water, add benzoin dimethyl ether (0.03 g) in ethanol solution (0.2 mL), stir for 12 hours, and irradiate 0.5 Hours, get nanometer particles. The solution was freeze-dried to obtain the desired nanoparticles.

Embodiment 3

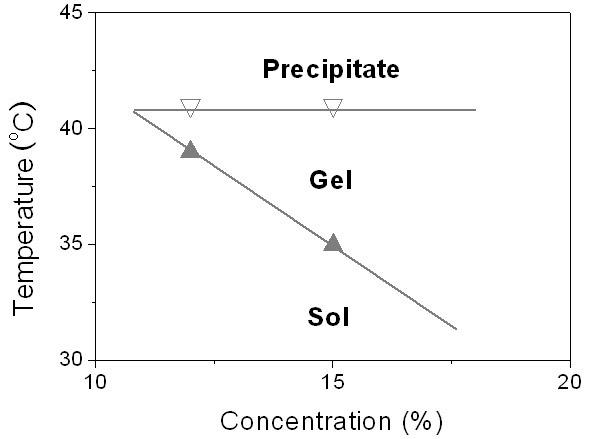

[0033] Example 3 The nanoparticles obtained in Example 2 were formulated into a 15 wt% solution, which showed a solution-gel transition when the temperature rose to 34 °C, realizing the overall physical gelation transition. like figure 2 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap