Refining method for producing stainless steel by VOD (vacuum oxygen decarburization) blowing CO2

A CO2 and stainless steel technology, applied in the field of out-of-furnace refining, can solve the problems of increased use of reduced alloys, large use of deoxidized alloys, and high dissolved oxygen content, reducing the use of alloys, good promotion and application prospects, and alleviating the greenhouse effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

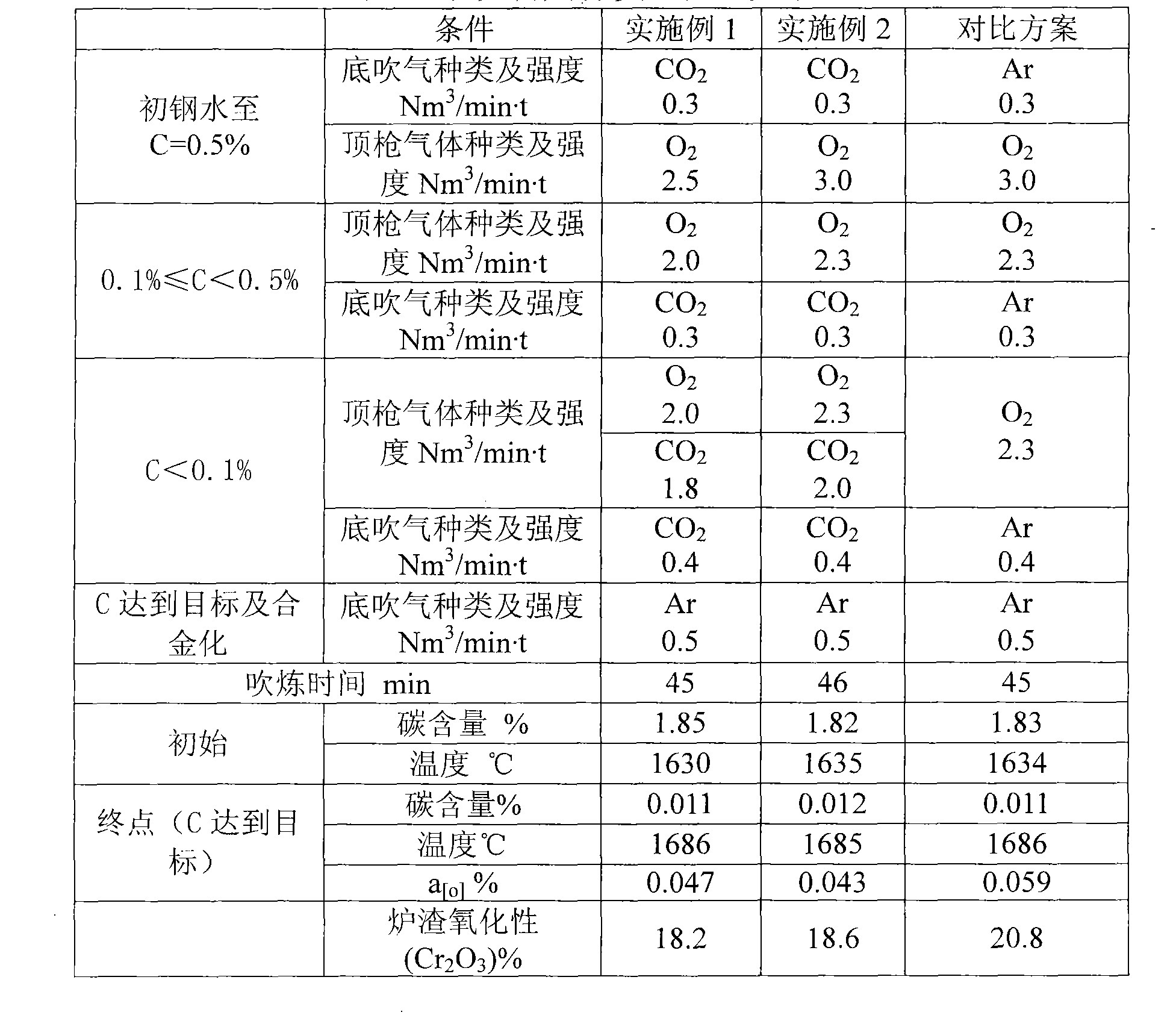

[0012] In order to achieve the best implementation effect, the following implementation methods are adopted as shown in Table 1. In the embodiment, the pressure of the bottom blowing gas is 0.6 MPa, and the pressure of the top blowing gas is 1.0 MPa. Injection gas concentration: O 2 99.6%, CO 2 99.4% and Ar 99.9%.

[0013] Table 1 Embodiment and effect of the present invention

[0014]

[0015] Using the above embodiment, it can be seen from the comparative examples that, under the condition that the initial condition of molten steel and the intensity of gas supply are basically the same, the final carbon content is basically the same, and the temperature is also basically the same, but the a[o] of molten steel is reduced by 24%, and the slag is oxidized Sex decreased by 11.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com