Vertical folded plating production line

An electroplating production line, folding technology, applied in the field of vertical folding electroplating production line, can solve the problems of increased labor intensity of equipment maintenance personnel, large friction resistance of the pressing plate type conductive wheel, large contact resistance of the conductive area, etc., to improve the electroplating effect, transmission Good stress effect and improved electroplating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Through specific examples, the present invention will be further described.

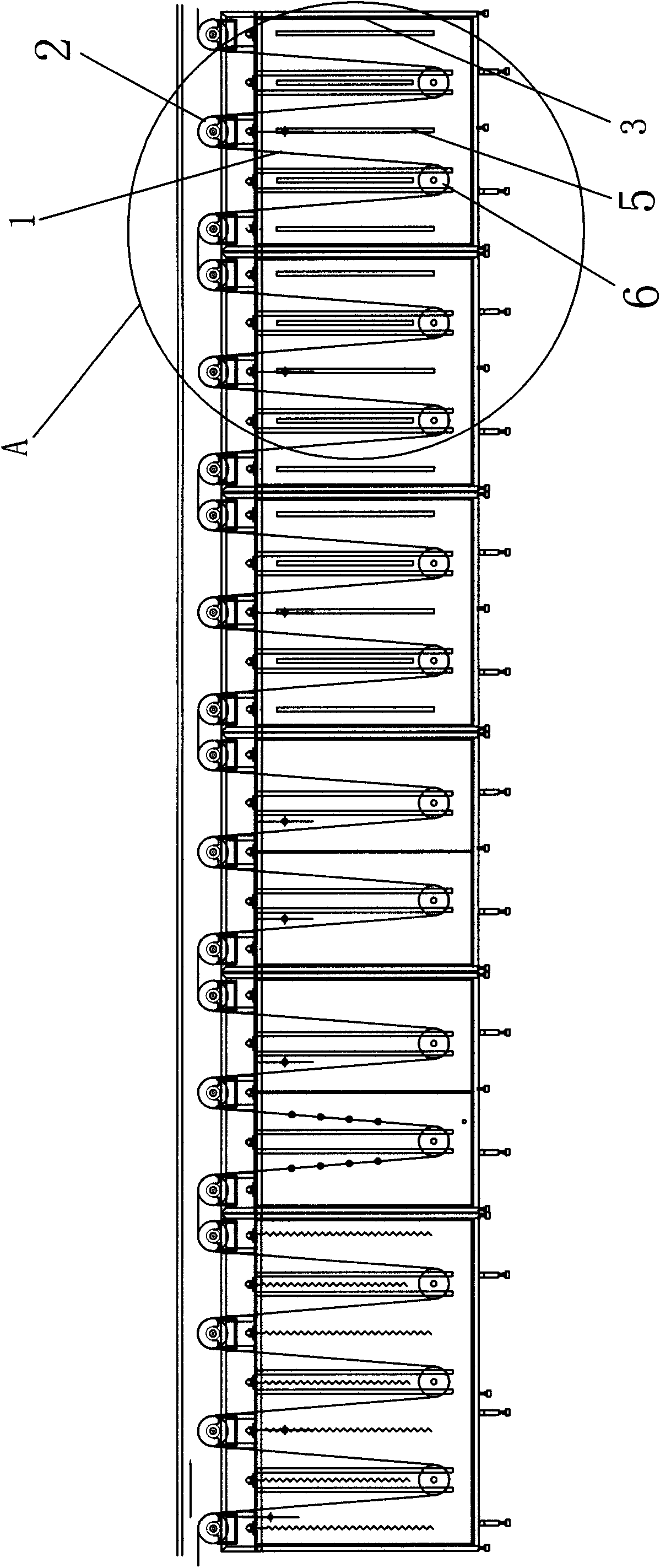

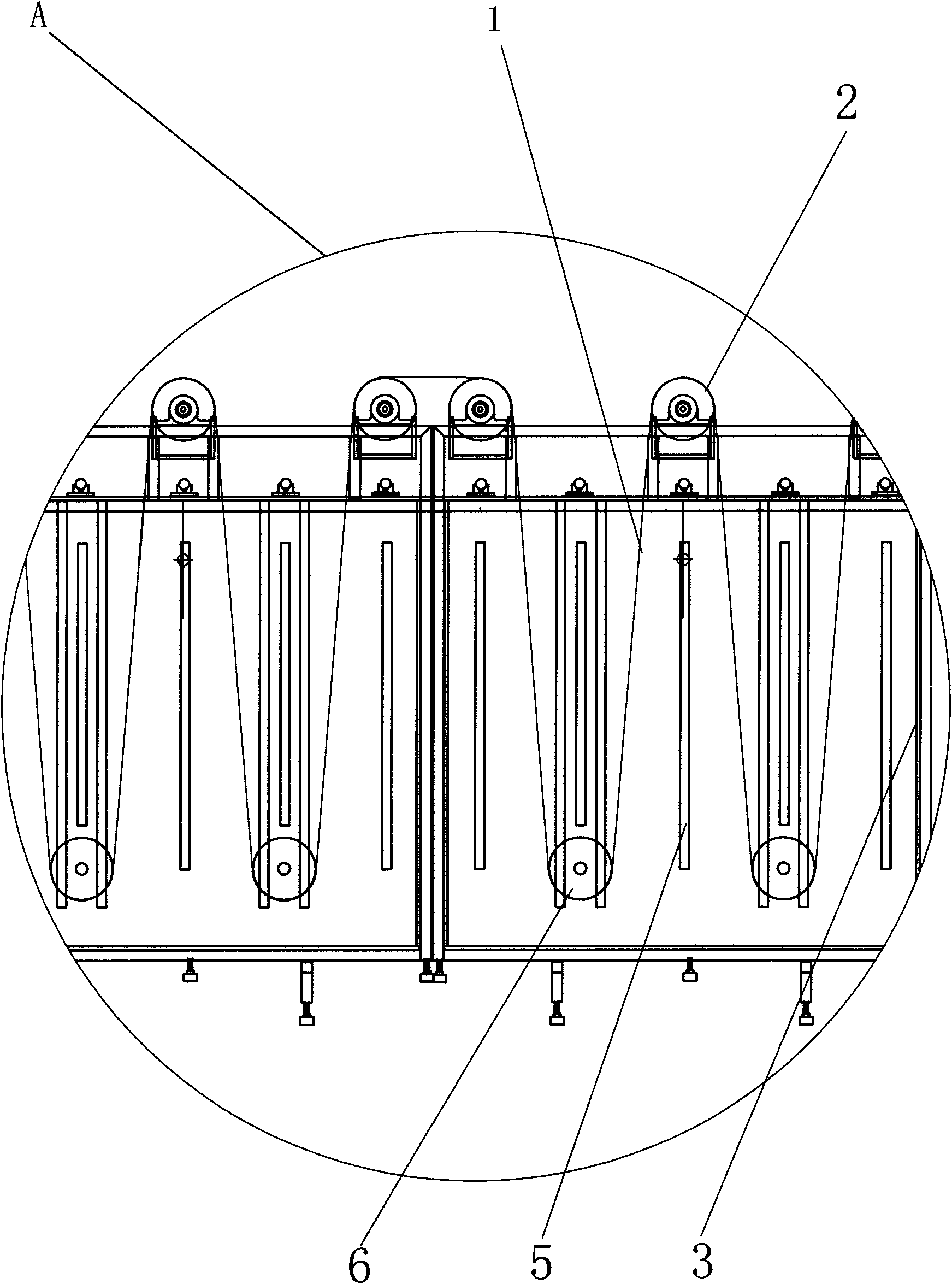

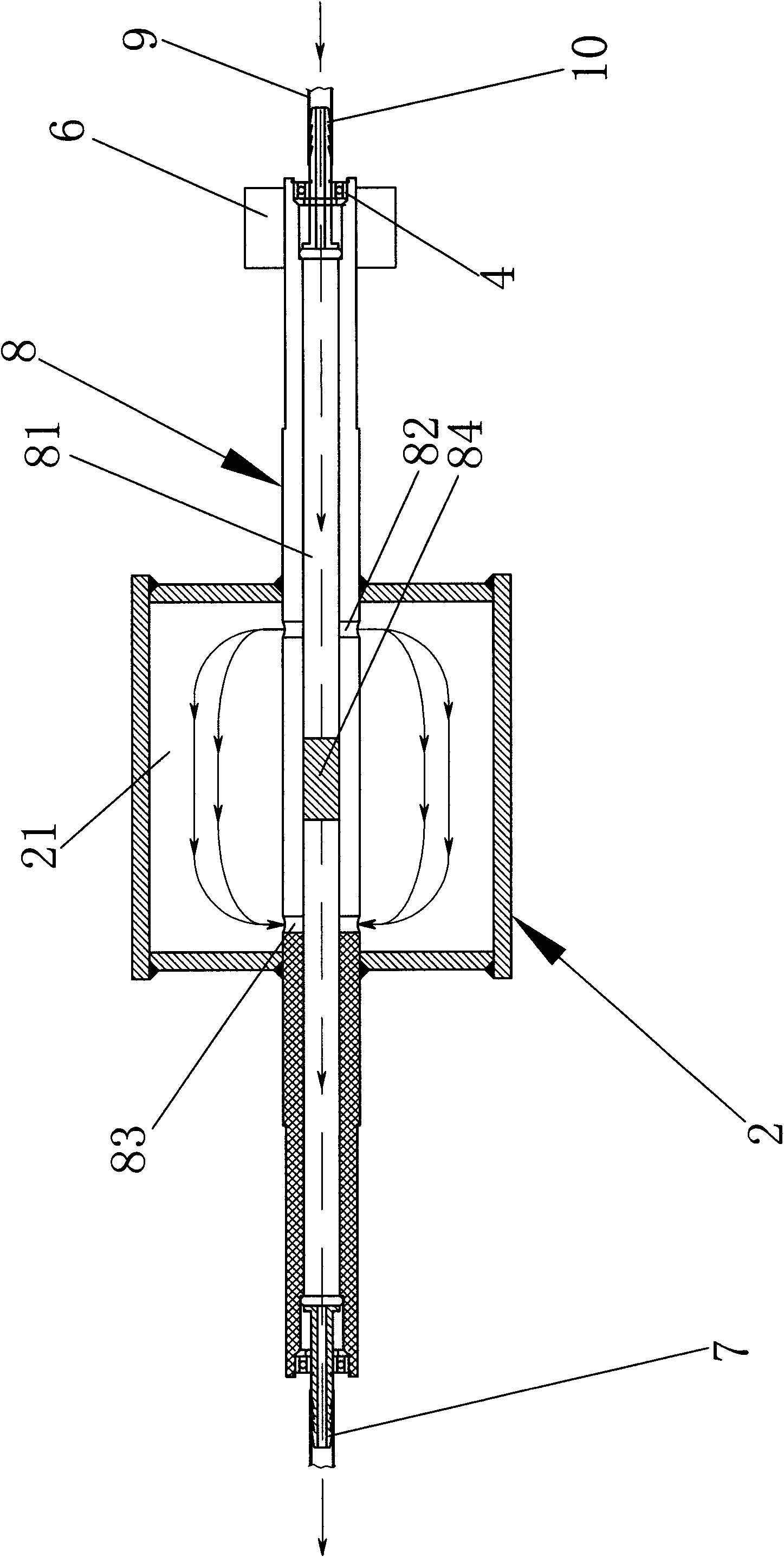

[0018] Such as figure 1 , the electroplating production line is composed of a plurality of electroplating process tanks 3 and multiple groups of electroplating wheel devices arranged in the electroplating process tank 3, and the electroplating process tank 3 is filled with different electroplating solutions or water, and electroplated parts of wire or strip 1. Through the conductive wheel 2 and the transmission wheel 6, the electroplating process tank 3 is turned up and down, and the plated material plate 5 is hung in the electroplating process tank 3. The anode of the electroplating power supply is connected to the plated material plate 5, and the cathode is connected to the plated material plate 5 through the brush 6. Conductive axle 8. During electroplating, the surface of the electroplating piece 1 is first degreased, cleaned, and activated, and then enters the electroplating process tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com