Lawn bed structure of athletic sports lawn

A technology for sports and lawn, applied in the field of lawn bed structure, can solve the problems of clogging drainage pipes, difficult to find, labor and money, etc., and achieves the effects of low construction cost, uniform force and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

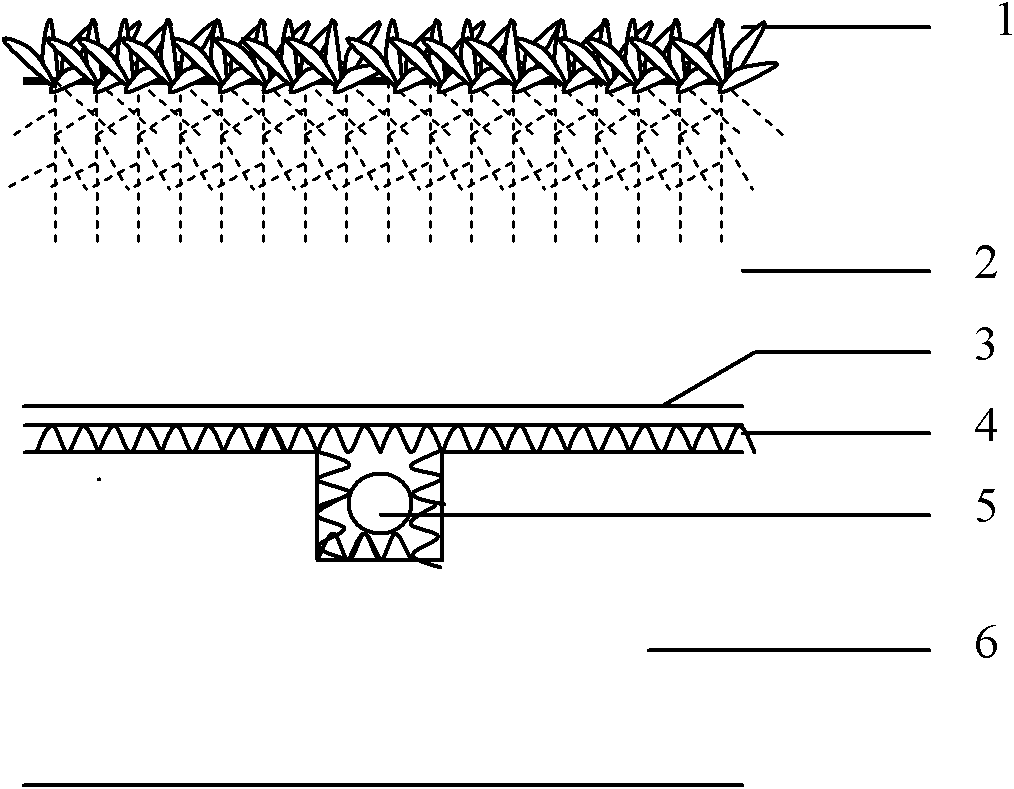

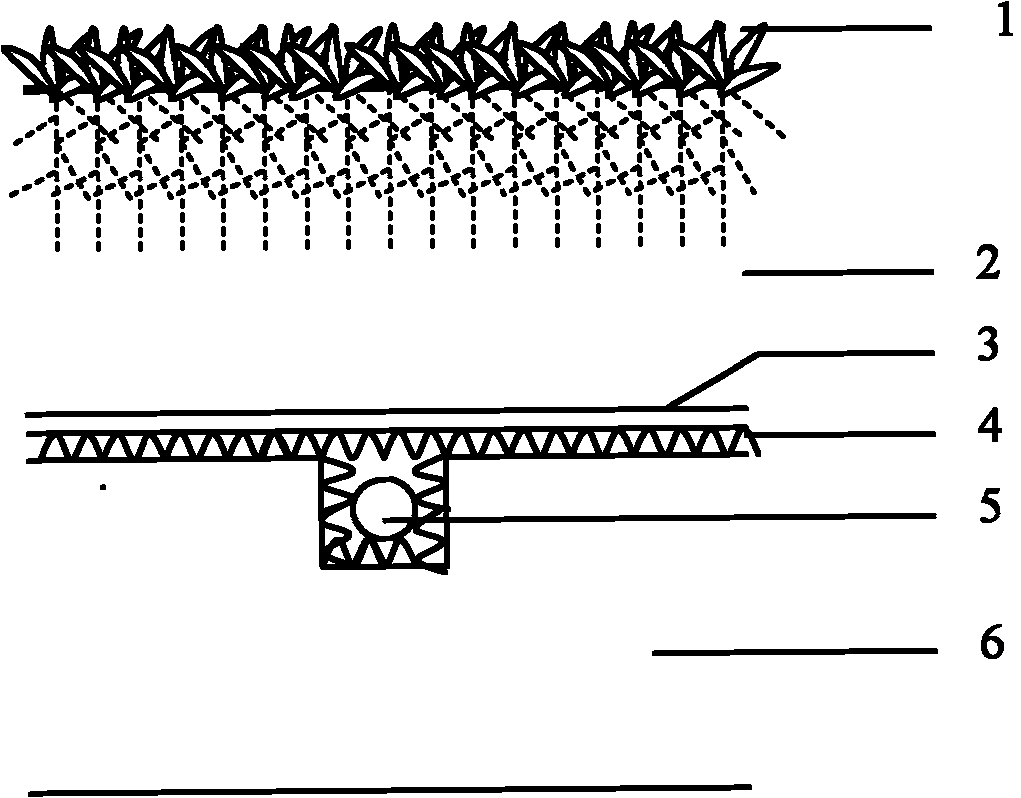

[0036] Football field sports lawn:

[0037] The sports lawn of a standard football field is 109 meters long and 72 meters wide. Drainage ditches are laid around the football field and covered with boards. The foundation is the original soil layer, which is repeatedly compacted with a road roller after watering. The foundation is slightly higher in the middle and slightly lower in the surrounding areas. The slope is generally controlled between 0.15% and 0.5% to facilitate surface drainage of the football field. Drainage ditches are opened on the foundation, and the drainage ditches are distributed in the shape of fish ridges. There is a main drainage ditch in the middle of the field, and side drainage ditches on both sides. ditch connected.

[0038] The double-sided concave-convex storage and drainage board with a compressive strength of more than 200kPa directly bonded to the non-woven fabric is directly laid on the compacted original soil layer, and two rows of concave-con...

Embodiment 2

[0041] golf course green

[0042] According to the designer's requirements, the green should be shaped, and the original soil foundation after modeling should be watered and compacted repeatedly. Drainage ditches are opened on the foundation after modeling, and the drainage ditches are distributed in the shape of fish ridges, and the distance between the drainage ditches is 3.5m. The double-sided concave-convex storage and drainage board with a compressive strength of more than 200kPa directly bonded to the non-woven fabric is directly laid on the compacted original soil layer, and the joint is kept with two rows of concave-convex holes overlapped and joined. The storage and drainage board is laid directly into the drainage ditch at the position of the drainage ditch, and the drainage pipe is placed on the storage and drainage board in the drainage ditch. Connect with the side drain pipe with a tee. After the installation of the drainage pipe is completed, cover the drainage...

Embodiment 3

[0045] school playground lawn

[0046] The school sports field often does not reach the area of a standard stadium, but drainage ditches are also laid around the sports field and covered with perforated cover plates. The foundation of the original soil layer needs to be watered and compacted repeatedly. The foundation is made slightly higher in the middle and slightly lower around. Drainage ditches are opened on the foundation, and the drainage ditches are distributed in the shape of fish ridges. There is a main drainage ditch in the middle of the sports field, with side drainage ditches on both sides, and the distance between the side drainage ditches is 5m.

[0047] The storage and drainage board bonded with non-woven fabric is directly laid on the compacted original soil layer. The storage and drainage board is a double-sided concave-convex storage and drainage board with a compressive strength of more than 200kPa, and two rows of concave-convex holes are overlapped at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com