Waste heat utilization system for internal combustion engine with antifreeze unit

A technology of internal combustion engine and waste heat circuit, which is applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., and can solve the problems of medium freezing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

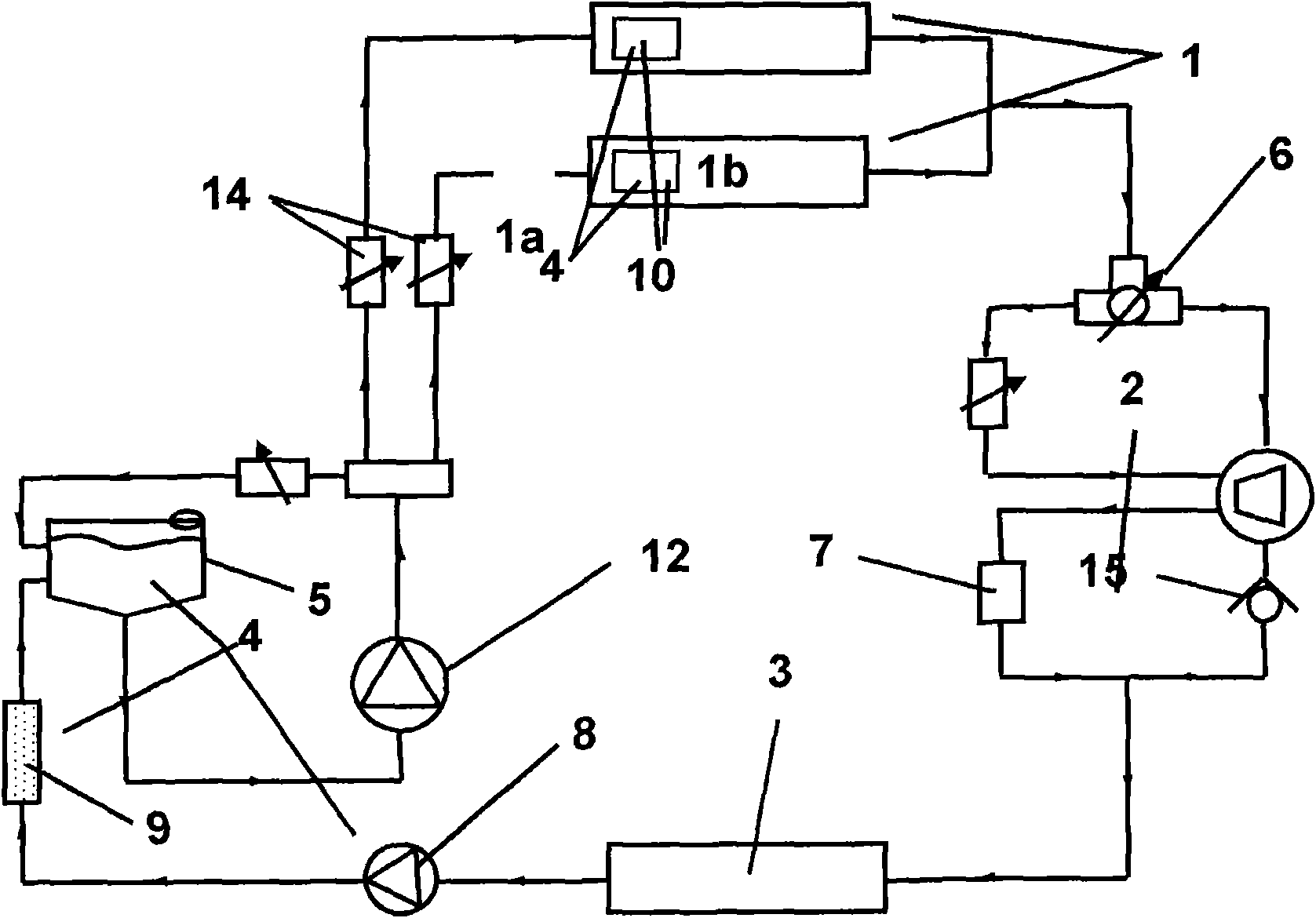

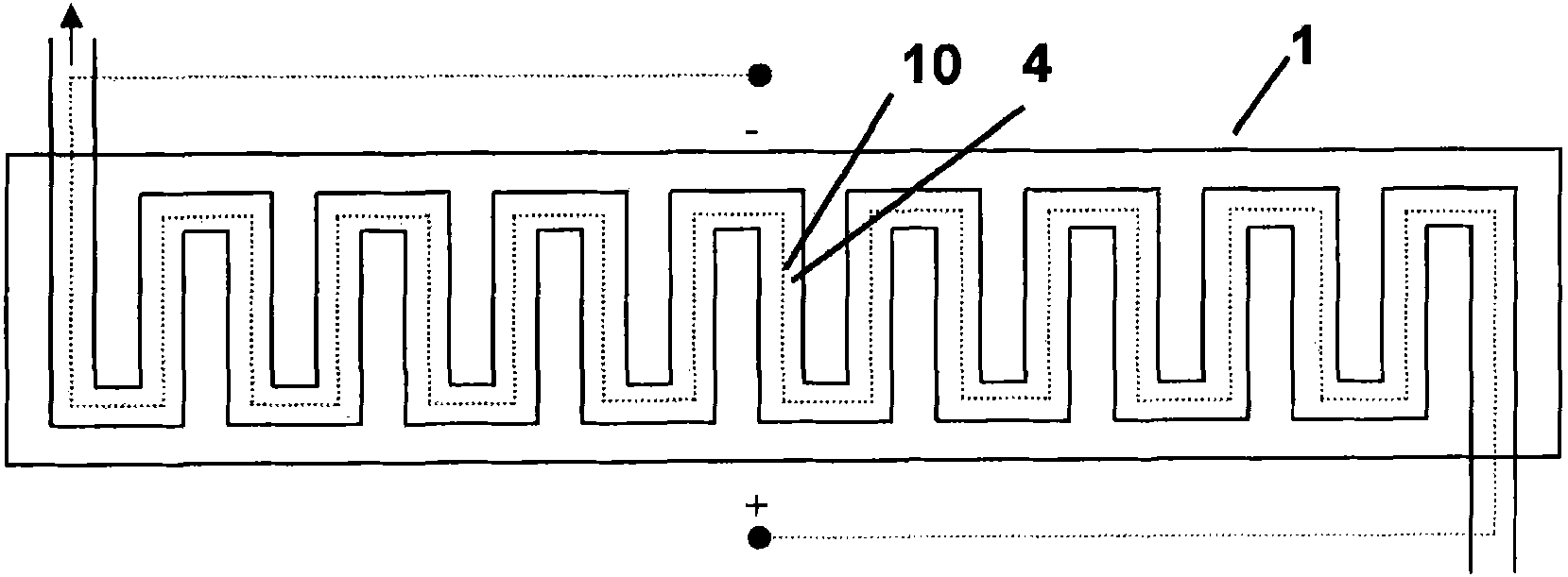

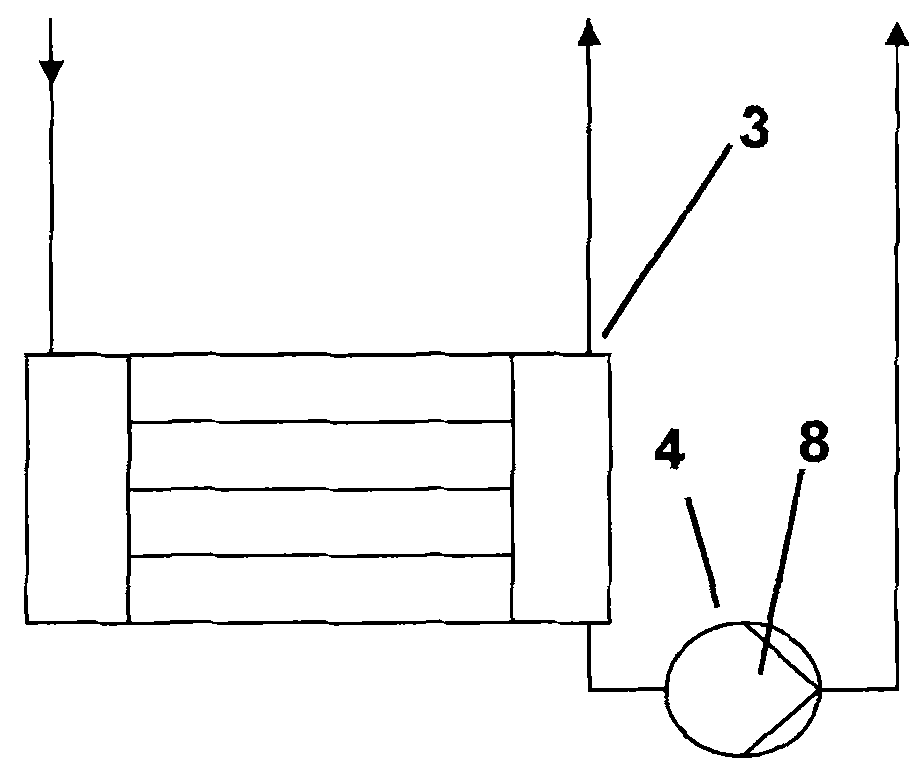

[0037] figure 1 Shown is a waste heat utilization circuit with which the waste heat of an internal combustion engine is converted into mechanical work. For this purpose, the waste heat generated in the internal combustion engine or in the exhaust system is first passed to the primary cooling circuit before it is supplied to the waste heat circuit designed as a secondary heat circuit. The main components required for waste heat utilization are: evaporator 1, in which the working fluid changes from liquid to vapor state; expansion unit 2, in which the working fluid in vapor state is decompressed, thereby outputting mechanical work ; Condenser, in which the working fluid is liquefied to its initial state before being evaporated.

[0038] elaborated below figure 1 The specifics of the device configuration shown in. The working fluid is input from the supply tank 5 into the waste heat utilization circuit by means of the supply pump 12 . The quantity of working fluid which is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com