Processing method of micro-component in multi-layer structure and solidified SU-8 photoresist sheet

A processing method and multi-layer structure technology, which is applied in the field of micro-machining, can solve the problems of damage to the upper layer pattern, unrealizable, irregular microstructure, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Now take the manufacture of a micro-component with a three-layer structure as an example for illustration.

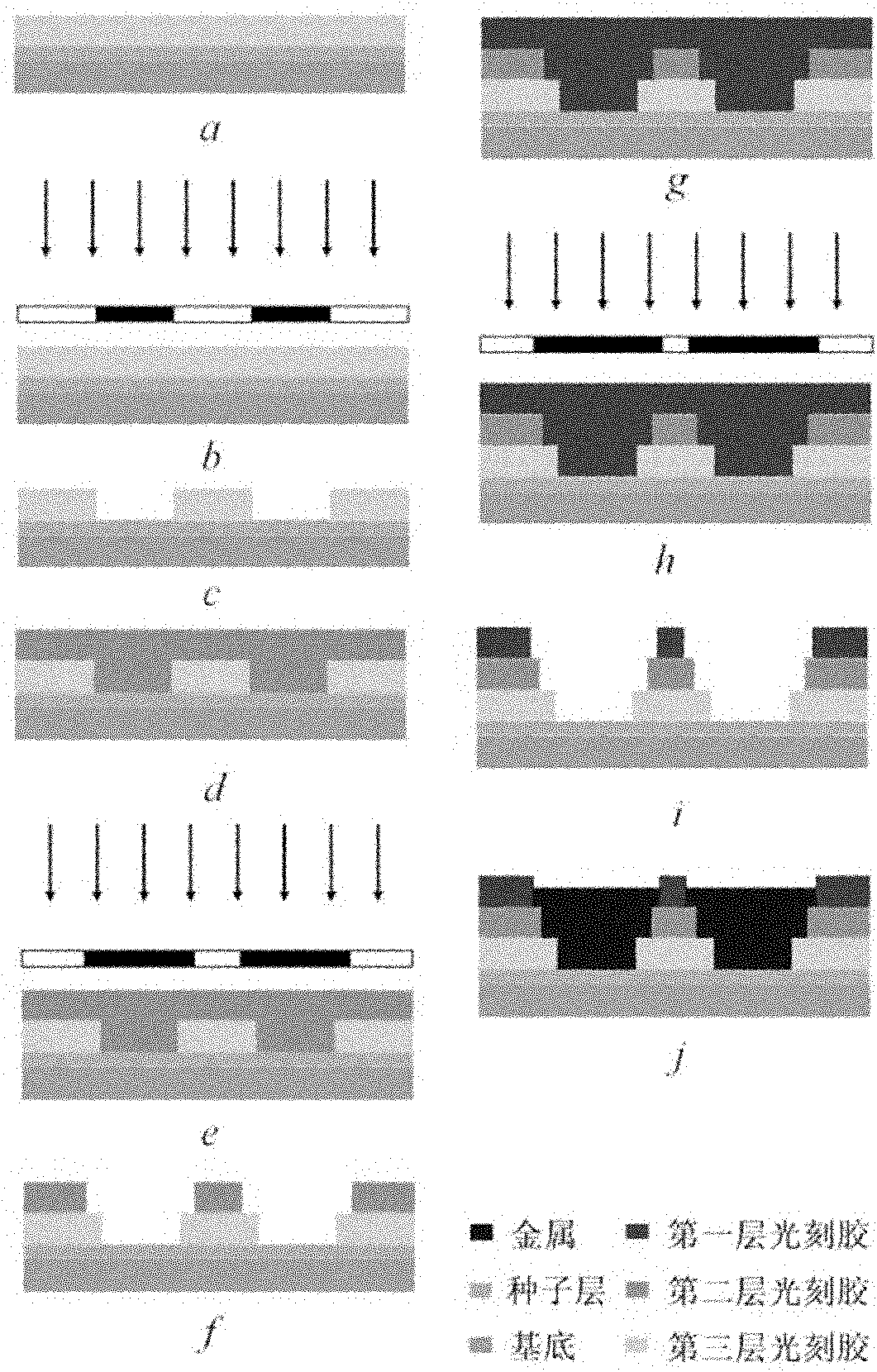

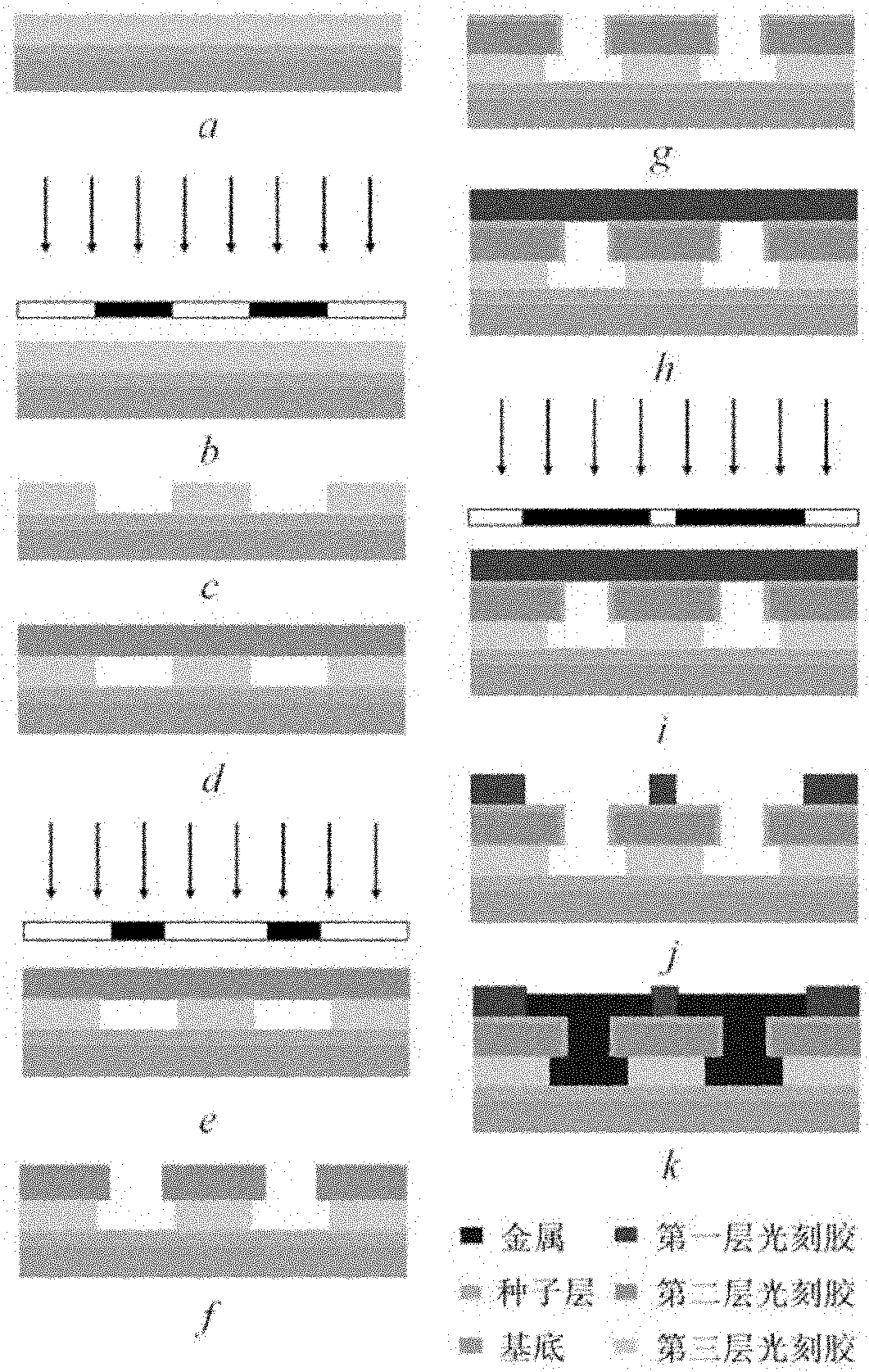

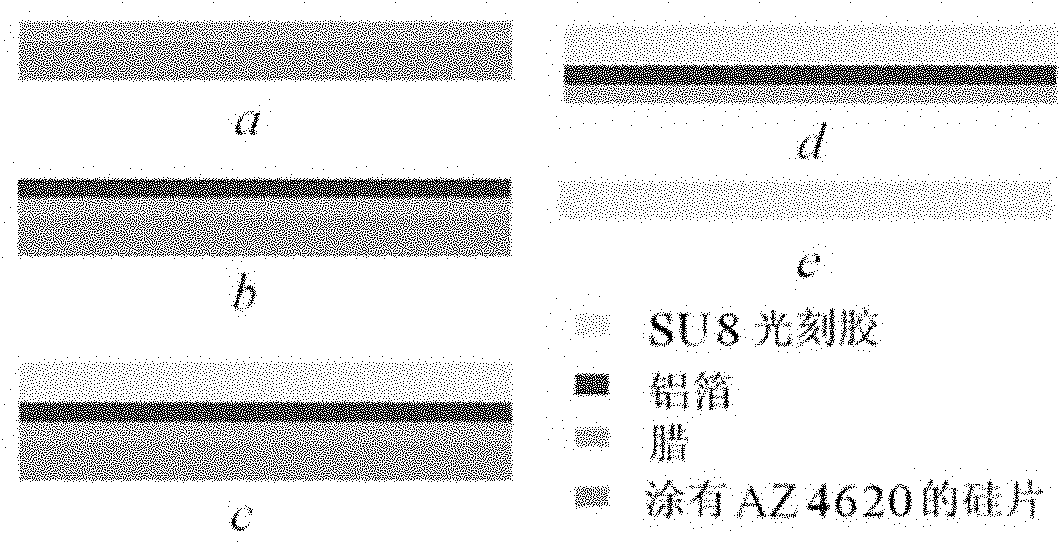

[0040] figure 2 It is the UV-LIGA flow chart of the multilayer structure of the present invention; among the figure (a) is uniform glue, (b, e, i) is exposure; (d, h) is pasted and cured SU8 sheet; (c, f, j) (g) is sputtering; (k) is electroforming.

[0041] Such as figure 2 Shown, the processing method of the microcomponent of multilayer structure of the present invention, comprises the following steps:

[0042] (a) Spread the glue on the substrate with the metal seed layer. The speed of the glue is related to the type of glue selected and the required thickness. Take SU82100 as an example, use 1000rpm to evenly glue the glue for 25 seconds, and the thickness of the glue is about 100 microns. After homogenizing the glue, bake the glue on the hot table: first set the temperature of the hot table at 65°C and keep it for 30 minutes, then raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com