Planar cutting tool and associated tool holder

A tool holder, cutting tool technology, applied in the direction of manufacturing tools, workpieces, drilling tool accessories, etc., can solve the problems of inaccuracy, difficult production, inferior tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

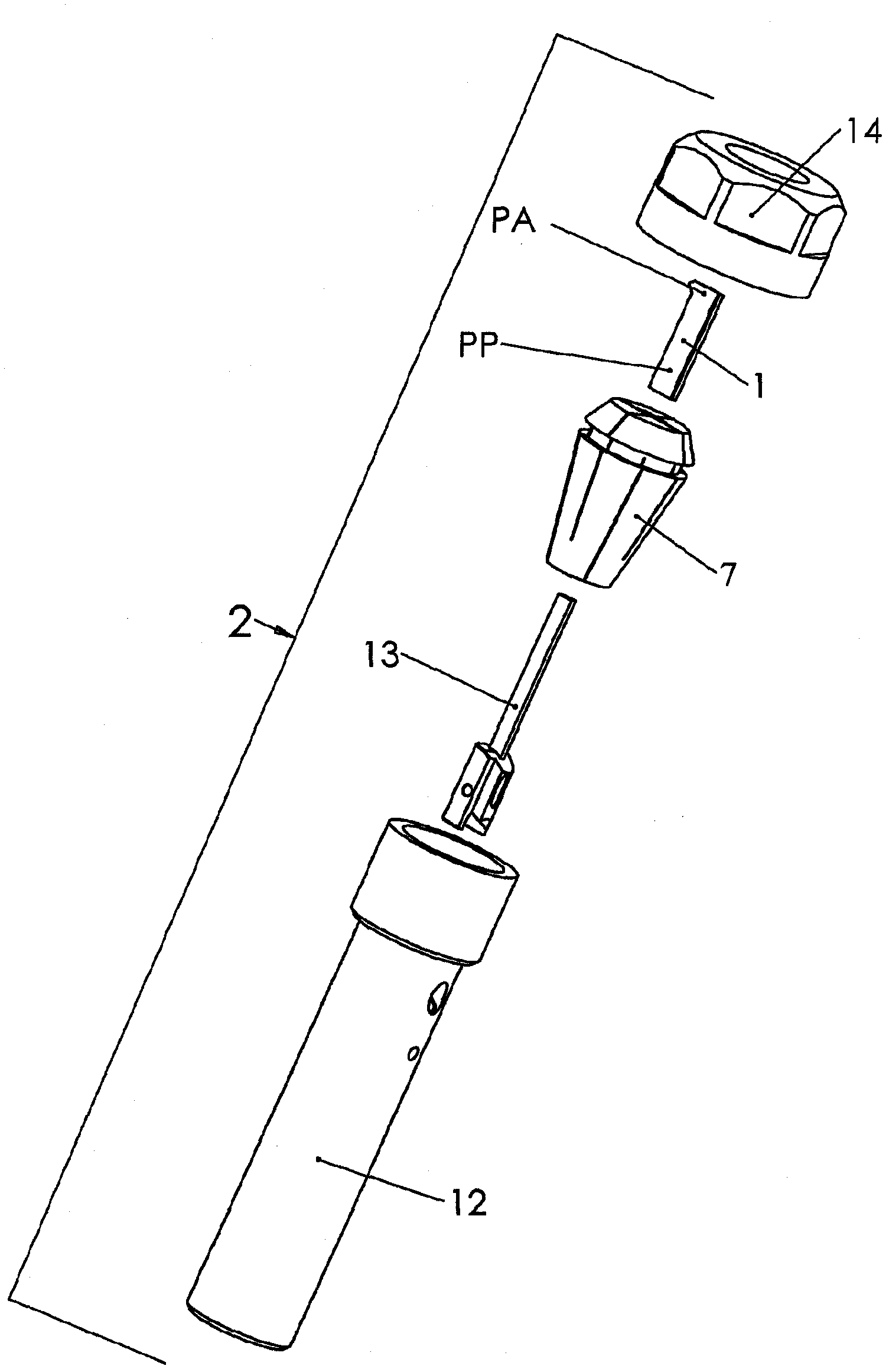

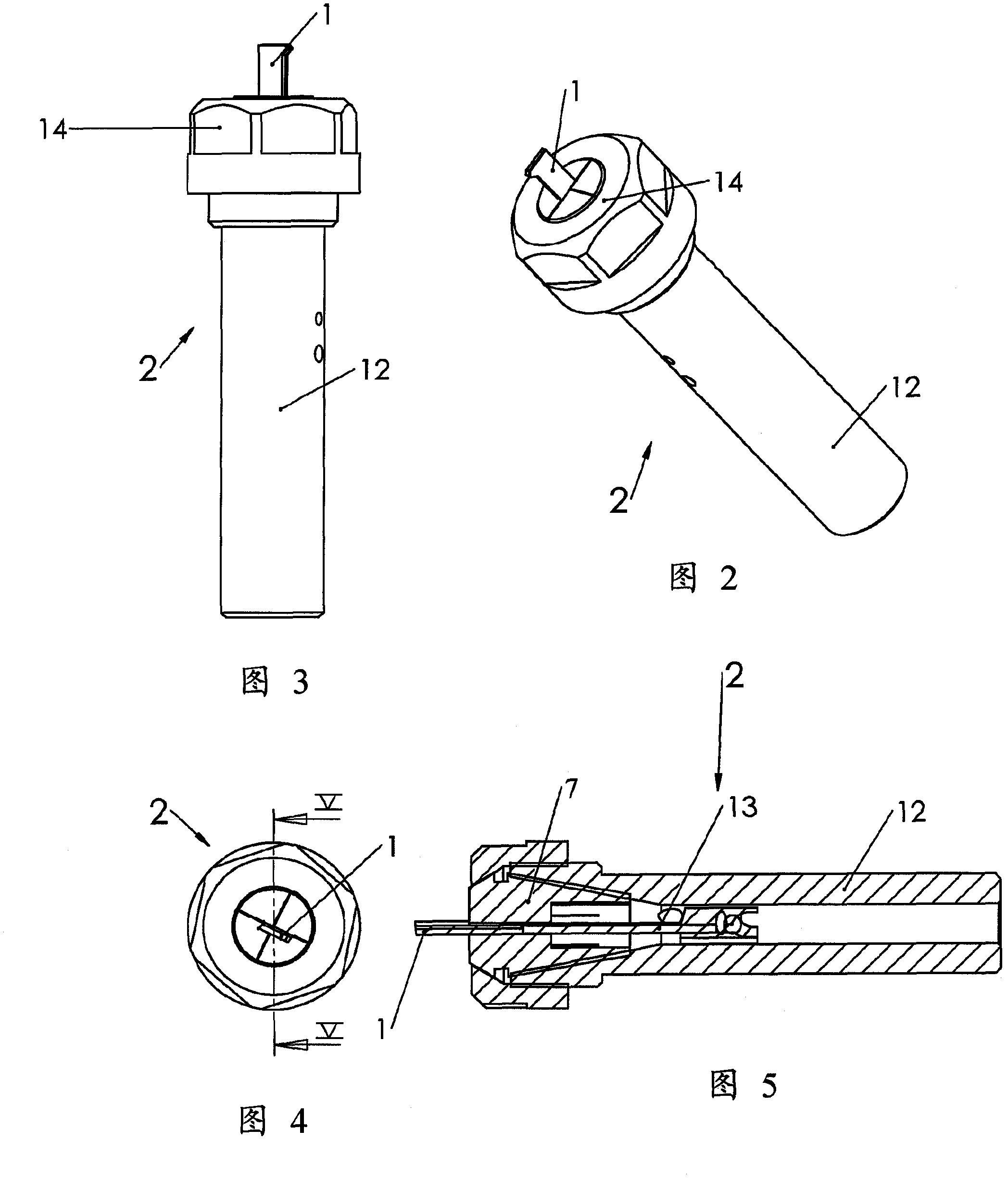

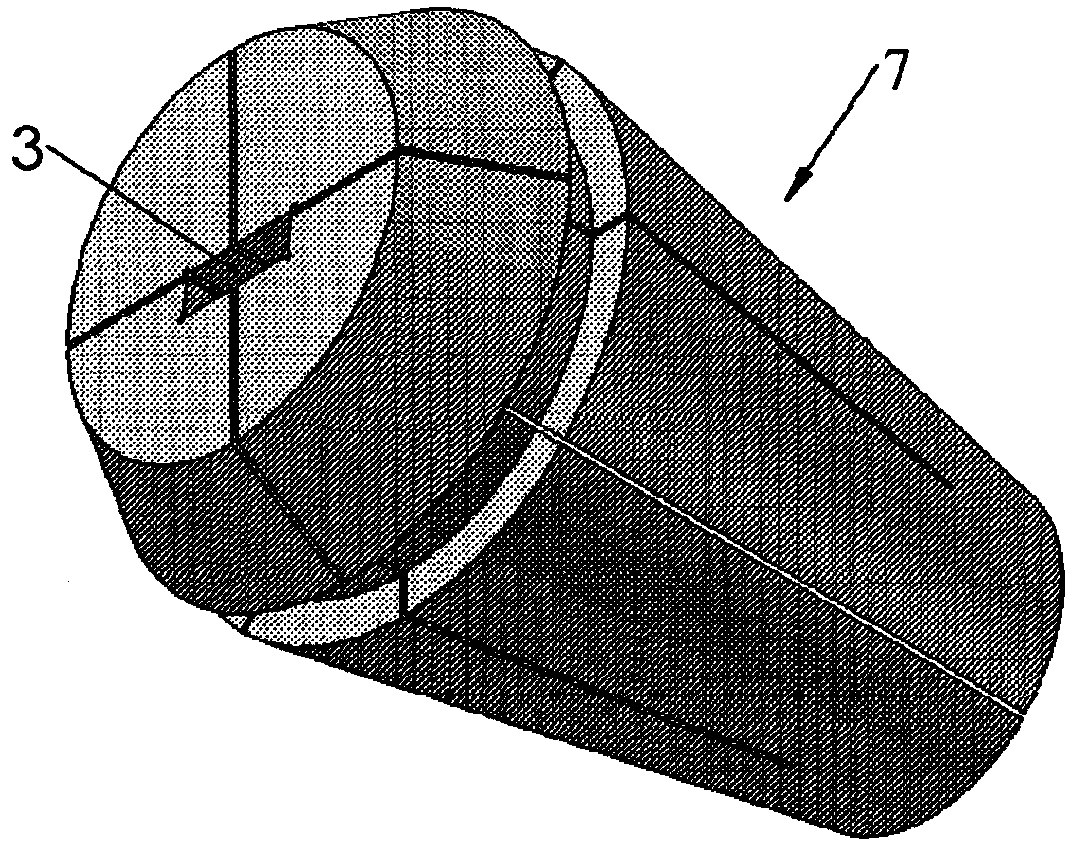

[0037] Depending on the use, the cutting tool 1 , 1A, 1B, 1C, 1D may be rotating or stationary, it is used for machining parts made of hard and / or abrasive materials, and the cutting tool 1 , 1A, 1B , 1C, 1D comprising: at least one active part whose hardness and / or abrasive properties are superior to those of the material to be machined; and a passive part for cooperating with the tool holder 2 including the gripper 7 .

[0038] According to a first characteristic of the invention, the active part "PA" and the passive part "PP" of said tool are formed by a one-piece plate delimiting these two parts to obtain a flat tool, which one-piece plate is obtained directly from the blank , the blank has a predetermined constant thickness and a hardness corresponding to the hardness of the active part "PA".

[0039] According to a second characteristic of the invention, the passive part "PP" of the same tooling plate is elongate and has a substantially quadrangular constant cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com