Ultralow-volume liquid containing ethofenprox

A technology of ultra-low volume liquid agent and etofenprox, which is applied in the direction of insecticide, biocide, animal repellent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

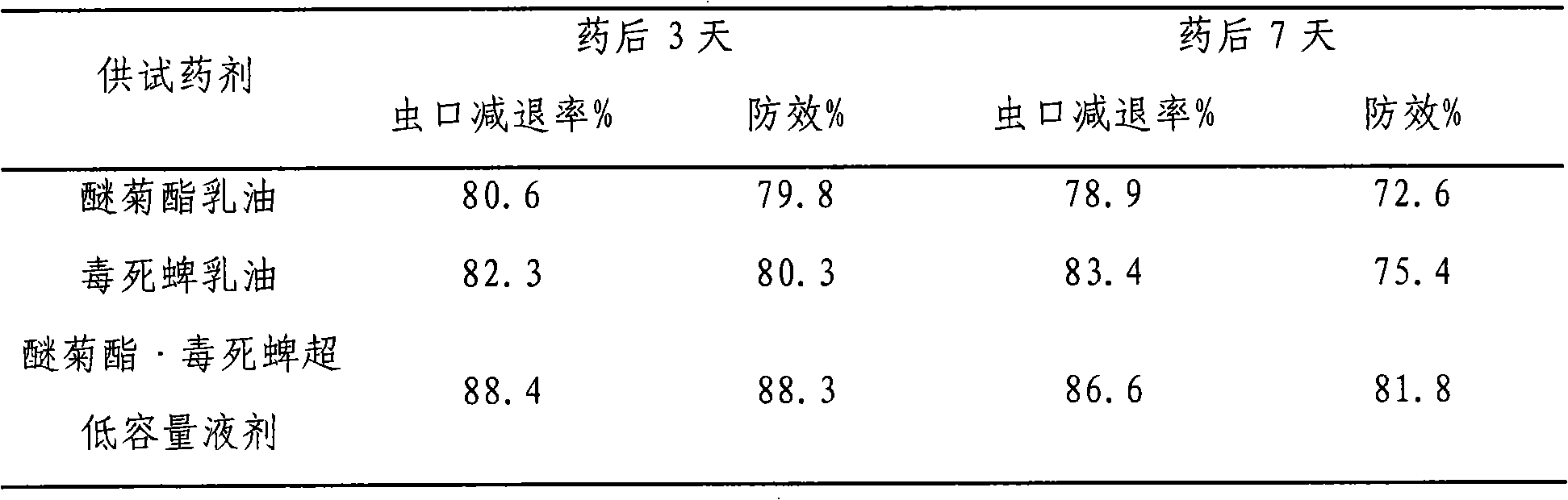

[0023] Embodiment 1, etofenproxil, chlorpyrifos ultra-low volume liquid

[0024] A, 2.0% etofenprox·chlorpyrifos ultra-low volume liquid 100kg

[0025] Based on the weight of the finished ultra-low-capacity oil agent as 100%, 1.0kg of etofenprox, 1.0kg of chlorpyrifos, 3.0kg of N-methylpyrrolidone, 2.5kg of sodium dodecylbenzenesulfonate, supplemented with second-line oil solvent to 100kg, poured Put it into the enamel stirring tank, stir for about 30 minutes, until it is completely transparent, and after the quality is qualified, the finished product is measured and packaged.

[0026] B. 12.0% Etoproxil·chlorpyrifos ultra-low volume liquid 100kg

[0027] Based on the weight of the finished ultra-low-capacity oil agent as 100%, 2.0kg of etofenprox, 10.0kg of chlorpyrifos, 5.0kg of N-methylpyrrolidone, 4.5kg of sodium dodecylbenzenesulfonate, the second-line oil solvent is added to 100kg, poured Put it into the enamel stirring tank, stir for about 30 minutes, until it is comp...

Embodiment 2

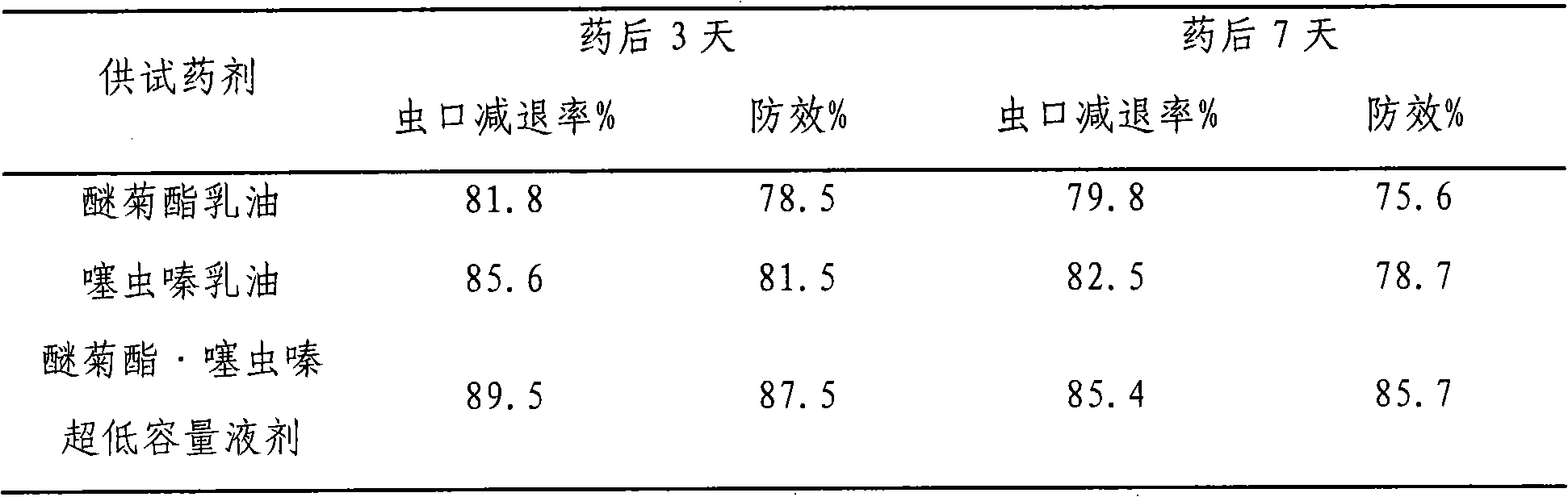

[0032] Embodiment 2, etofenproxil, thiamethoxam ultra-low volume liquid

[0033] A, 2.0% etofenproxil·thiamethoxam ultra-low volume liquid 100kg

[0034] Calculated based on the weight of the finished ultra-low-capacity oil agent as 100%, 1.0kg of etofenprox, 1.0kg of thiamethoxam, 3.0kg of N-methylpyrrolidone, 2.5kg of sodium dodecylbenzenesulfonate, and 100kg of second-line oil solvent , pour it into an enamel stirring kettle, stir for about 30 minutes until it is completely transparent, and after the quality is qualified, the finished product is measured and packaged.

[0035] B, 12.0% etofenprox·thiamethoxam ultra-low volume liquid 100kg

[0036]Calculated based on the weight of the finished ultra-low-capacity oil agent as 100%, 2.0kg of etofenproxil, 10.0kg of thiamethoxam, 5.0kg of N-methylpyrrolidone, 4.5kg of sodium dodecylbenzenesulfonate, and 100kg of second-line oil solvent , pour it into an enamel stirring kettle, stir for about 30 minutes until it is completely ...

Embodiment 3

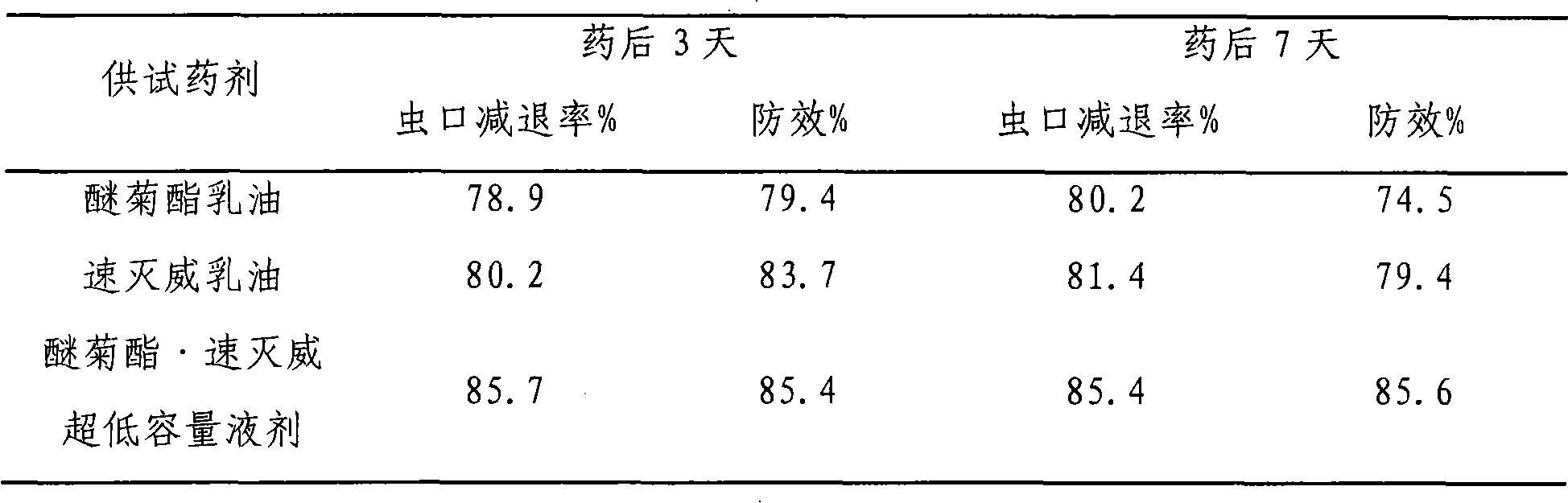

[0041] Embodiment 3, etofenproxil, amecarb ultra-low volume liquid

[0042] A, 2.0% etofenproxil·methicarb ultra-low volume liquid 100kg

[0043] Calculated based on the weight of the finished ultra-low-capacity oil agent as 100%, 1.0kg of etofenproxil, 1.0kg of memocarb, 3.0kg of N-methylpyrrolidone, 2.5kg of sodium dodecylbenzenesulfonate, and supplemented with second-line oil solvent to 100kg , pour it into an enamel stirring kettle, stir for about 30 minutes until it is completely transparent, and after the quality is qualified, the finished product is measured and packaged.

[0044] B. 12.0% Etoproxil·Medolcarb ultra-low volume liquid 100kg

[0045] Calculated based on the weight of the finished ultra-low-capacity oil agent as 100%, 2.0kg of etofenproxil, 10.0kg of memocarb, 5.0kg of N-methylpyrrolidone, 4.5kg of sodium dodecylbenzenesulfonate, and 100kg of second-line oil solvent , pour it into an enamel stirring kettle, stir for about 30 minutes until it is completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com