Welding method for welding columns of encapsulated integrated circuit (IC)

A welding method and integrated circuit technology, applied in the direction of circuits, welding equipment, electrical components, etc., can solve problems such as crack expansion in the welding layer, open circuits, and affecting the welding strength of soldering pillars of packaged products, so as to improve the yield and quality of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

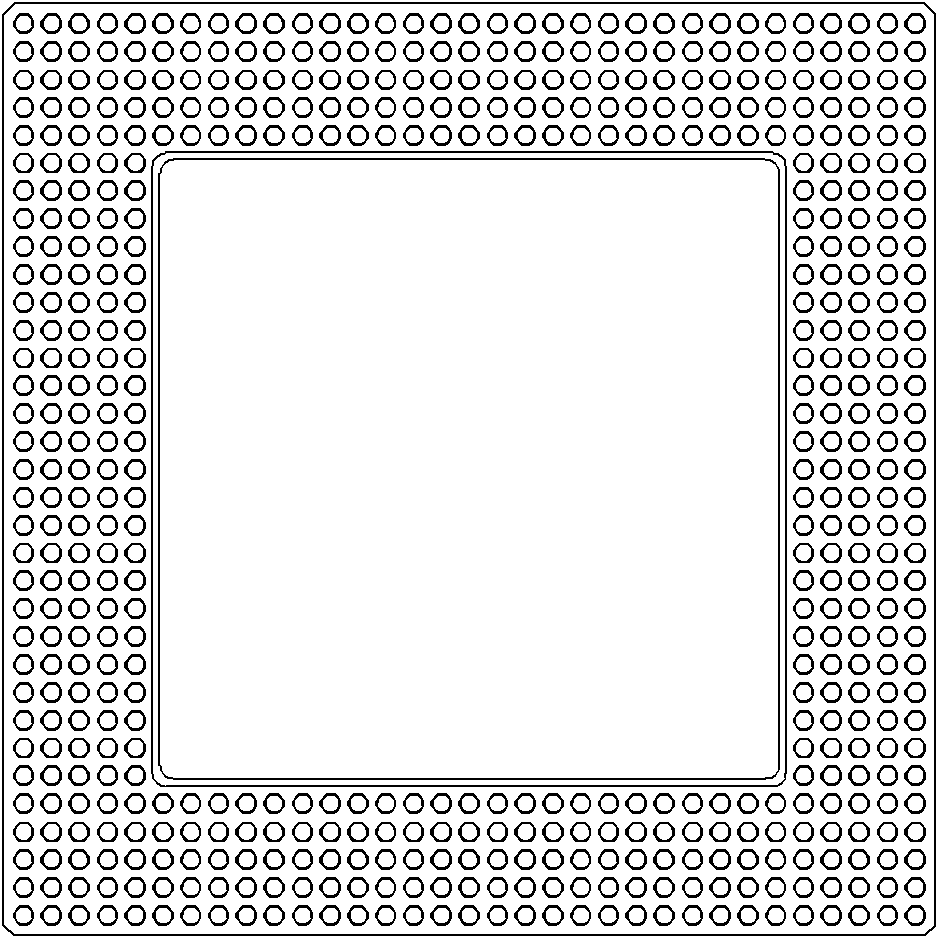

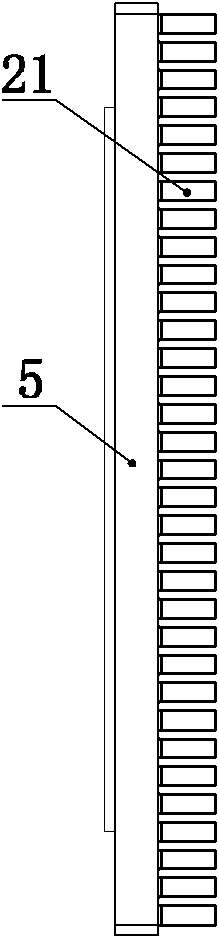

[0030] Such as figure 1 , figure 2 As shown, a CCGA560 packaged product with a pitch of 1.27 mm is assembled with a Sn10Pb90 solder column 21 with a diameter of φ0.89 mm. The post welding method of this product includes the following steps:

[0031] (1) Neatly arrange the Sn10Pb90 solder columns 21 with a diameter of φ0.89mm in the special mold 1;

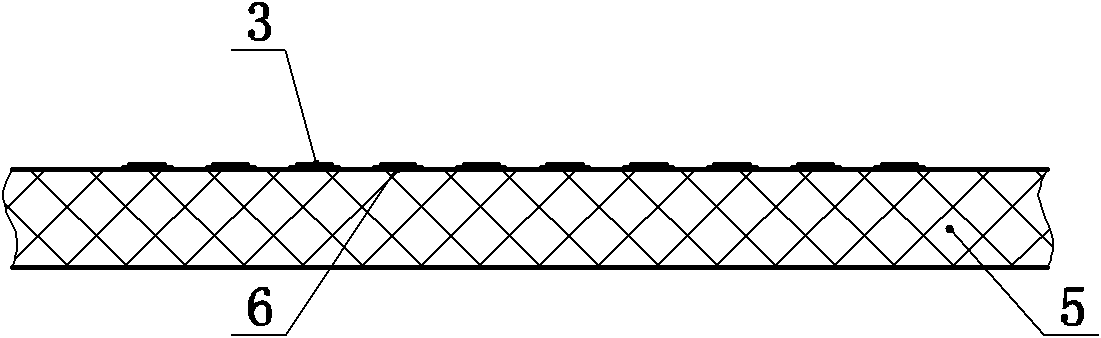

[0032] (2) Print solder paste 3 (Sn63Pb37, etc.) on the pad 6 of the substrate 5 to be planted, see image 3 ; The diameter of the solder paste 3 is: 0.89mm, and the thickness of the solder paste is: 0.20mm.

[0033] (3) Put the to-be-planted substrate 5 printed with solder paste 3 on the pad 6 into a bench-top nitrogen lead-free reflow furnace. The reflow furnace is produced by Beijing Qixing Tianyu Technology Co., Ltd., and the equipment model is TYR108N. The solder paste 3 is melted by a reflow oven, and the solder paste 3 forms a half-moon spherical crown on each pad 6, which is the convex solder 4, see Figure 4 ;The ref...

Embodiment 2

[0038] Such as Figure 7 , Figure 8 As shown, a CCGA575 packaged product with a pitch of 1.27 mm is assembled with an oxygen-free copper metal post 22 with a diameter of φ0.60 mm. The post welding method of this product includes the following steps:

[0039] (1) Neatly arrange the oxygen-free copper metal pillars 22 with a diameter of φ0.60mm in the special mold 1;

[0040] (2) Print solder paste 3 with a diameter larger than that of the metal pillar 22 on the pad 6 of the substrate 5 to be planted. The solder paste grade is such as INDIUM's IPN: 82342, the diameter of the solder paste is 0.82mm, and the thickness of the solder paste is 0.15mm. See Figure 9 ;

[0041] (3) Put the substrate 5 to be planted with the solder paste 3 printed on the pad 6 into the heating table, and melt the solder paste 3 through the heating table, and the solder paste 3 forms a half-moon spherical crown on each pad 6, That is, convex solder 4, see Figure 10 ;The melting of the heating tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com