All-in-one machine for milling and grinding numerical control spline shaft

An all-in-one machine, spline shaft technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high purchase price of hob, low degree of automation, single function, etc., and achieve the effect of convenient and fast replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

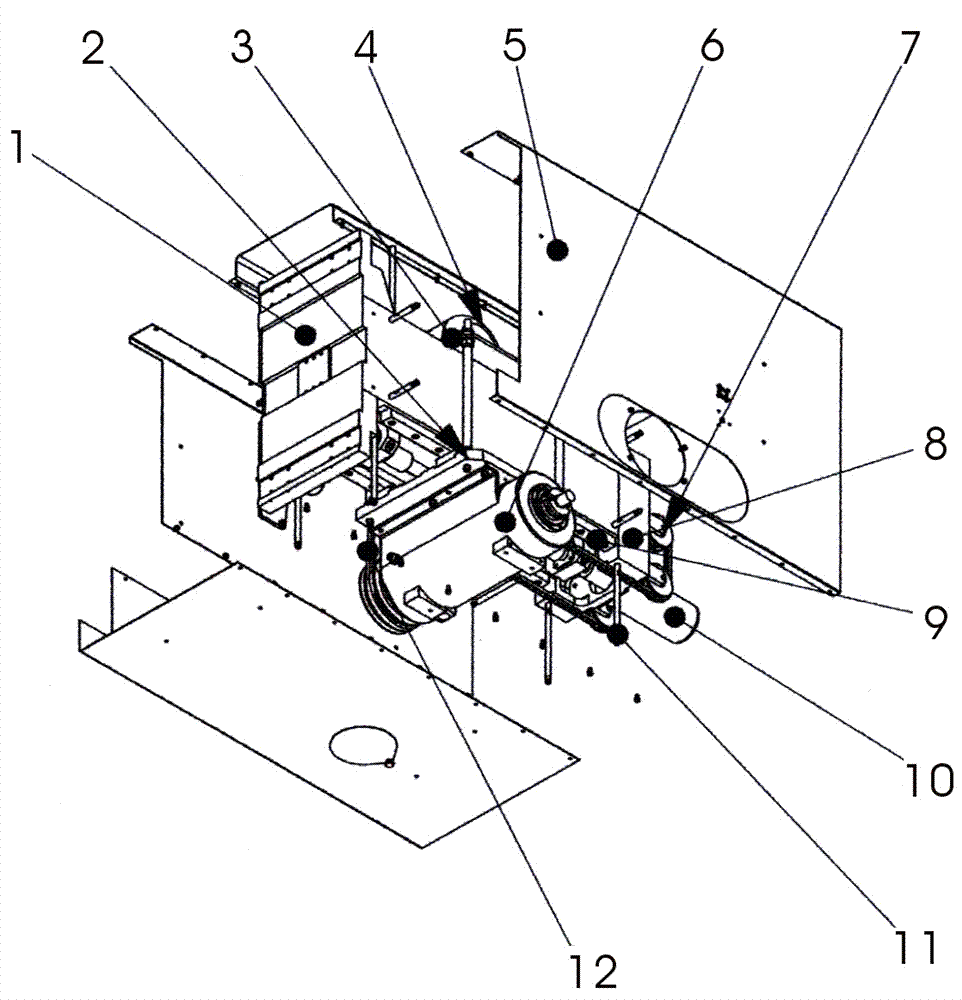

[0007] Now refer to the attached figure 1 , the description is as follows in conjunction with the embodiment: The CNC spline shaft milling and grinding machine according to the present invention includes a column 1, a milling head fixing plate 2, a motor fixing plate 3, a motor 4, a support shield 5, a milling head 6, a Heavy 7, fixed seat 8, linear slide rail 9, feeding device 10, connecting bolt 11 and belt pulley 12 form. One side of the column 1 is equipped with a milling head fixing plate 2 and a linear slide rail 9, the milling head fixing plate 2 is equipped with a milling head 6 or a grinding head, and the feeding device 10 drives the milling head 6 or grinding head through the milling head fixing plate 2 The head moves up and down; the other side of the column 1 is equipped with a motor fixing plate 3, and a motor 4 is arranged on the motor fixing plate 3. The motor 4 is adjusted by a frequency converter, and the milling head 6 or the grinding head is driven to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com