Special multifunctional multi-shaft numerically controlled clamp for processing centrifugal vane wheel, and manufacturing and installation method of special multifunctional multi-shaft numerically controlled clamp

A technology of centrifugal impeller and special fixture, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing efficiency, increasing production cost, general performance limitations of fixtures, etc., and achieves the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

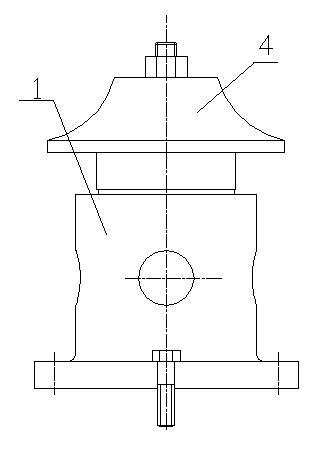

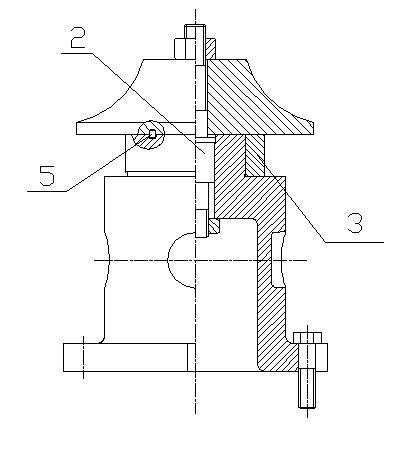

[0024] A multi-functional centrifugal impeller multi-axis CNC machining special fixture, which consists of: a fixture main body 1, the upper end of the fixture main body 1 is connected to a fixed mandrel 2, and a size-variable adaptable ring sleeve 3 is housed in the described fixture main body 1. The upper end of the fixed mandrel 2 is connected to the impeller blank 4 , and the impeller blank 4 is connected to the workpiece repositioning pin 5 .

Embodiment 2

[0026] A manufacturing and installation method of a special fixture for a multifunctional modular centrifugal impeller. The special fixture is composed of four parts: a fixture main body, a fixed mandrel, a size-changing adaptation ring sleeve, and a workpiece repositioning; Install and start the mandrel on the machine; fix the mandrel, install and fix it on the main body of the fixture by means of threaded connection, and form a positioning surface with the main body of the fixture or the variable size adaptation module for workpiece processing and positioning; the diameter of the mandrel can be changed according to the requirements of the center hole of the impeller ;The mandrel passes through the center hole of the impeller, and the workpiece is fixed by the nut thread, and the size is changed to adapt to the annular structure of the ring sleeve, which is detachably connected to the fixture main body by using a cylindrical combination; the change is adjusted by changing the o...

Embodiment 3

[0028] The manufacturing and installation method of the special fixture for multifunctional modular centrifugal impeller described in Example 2, if the workpiece needs to be clamped twice, the positioning hole is processed on the impeller before clamping, and then repositioning is carried out by connecting with the repositioning pin .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com