Device for cutting off diaper finished product with elastomer and method for preventing displacement of cut-off diaper finished product

A cutting device and trousers finished product technology, applied in the field of diaper production equipment, can solve the problems of inconsistent product length, large space occupation, complex structure, etc., and achieve the effect of improving cutting quality, small occupation space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

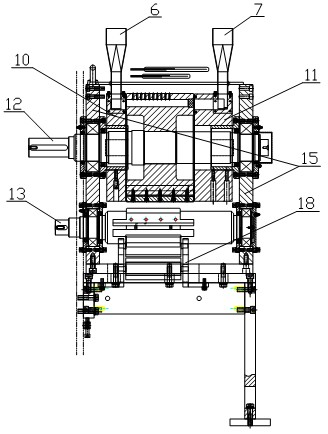

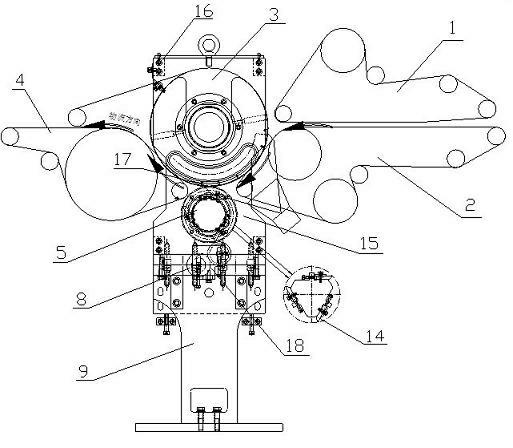

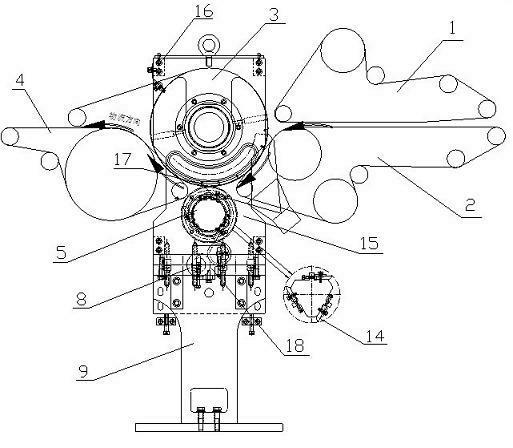

[0010] Embodiment 1: with reference to attached figure 1 and 2 . The cutting device for finished diapers with elastic body, the cutting roller connecting shafts 5, 13 and the knife felt roller connecting shafts 3, 12 are installed in the overall frame composed of the knife rest plate 15 and the spacer plate 16, and then installed on the mounting frame 9 Lubricating roller 8 is installed below the cutting roller shafts 5 and 13; after the air distribution discs 10 and 11 and the air suction ports 6 and 7 are assembled externally, they are assembled to the knife felt roller and transfer roller 3 according to the suction area required by the device On both sides, seal with felt.

[0011] The cutting roller shafts 5 and 13 are completed by the cutting roller 5 being installed on the cutting roller power shaft 13;

[0012] Three cutting blades 14 are installed on the cutting roller 5, and the clamping angle between each cutting blade 14 is 60 degrees.

[0013] The lubricating r...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, the finished product of diapers with elastic body is attached figure 1 The direction shown enters the cutting device. When the finished product enters the conveying section between the knife felt roller and transfer roller 3 and the lower pressure belt 2, the lower pressure belt 2 has a pressure on the product, and the suction port 7 of the suction area of the feeding port is in the knife. An internal negative pressure is generated on the felt roller and transfer roller 3, and the finished product is firmly adsorbed on the surface of the knife felt roller and transfer roller 3 under the action of the above-mentioned double force. At the position of point 17, the cutting blade 14 on the cutting roller 5 cuts off the finished product at the designated position, and the finished product after cutting is subjected to the strong suction force generated by the suction port 6 in the strong suction area, and its two ends are tightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com