Automatic bottle blowing production line

An automatic production line and automatic technology, applied in glass blowing, glass forming, application, etc., can solve the problems of low work efficiency, low degree of automation, and a large number of manual operations, and achieve the effect of saving manpower and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific example

[0013] The present invention will be specifically and further described below in conjunction with the accompanying drawings.

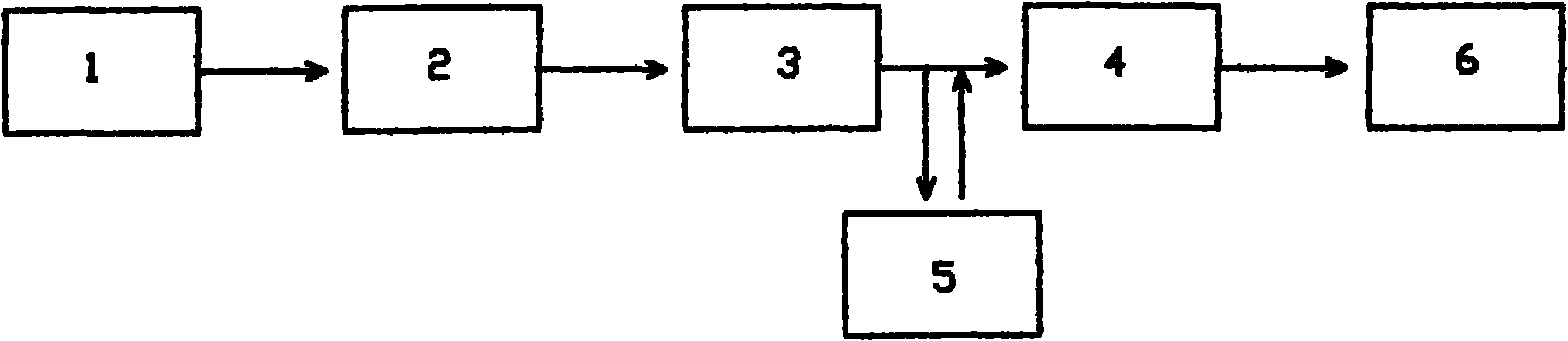

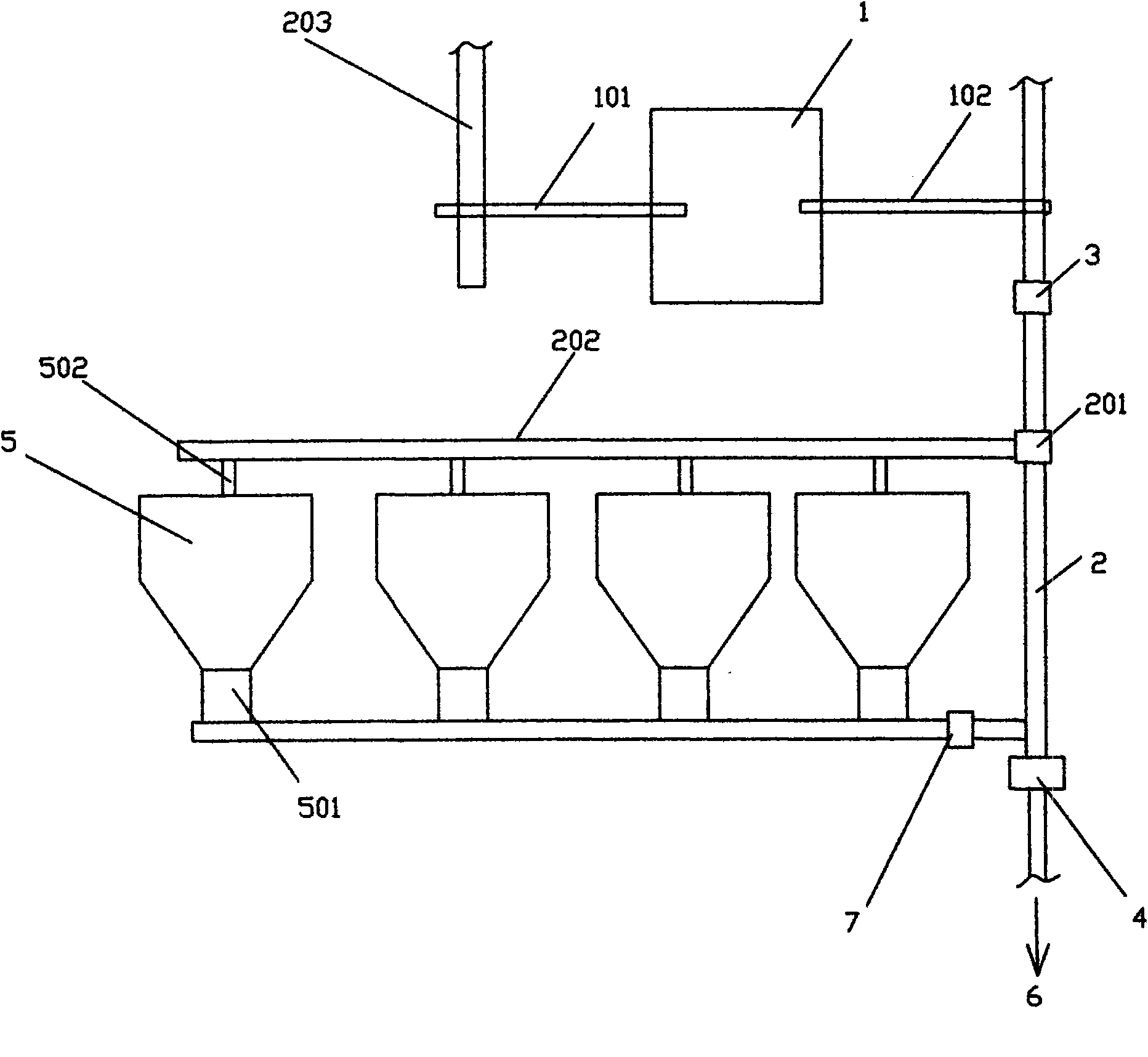

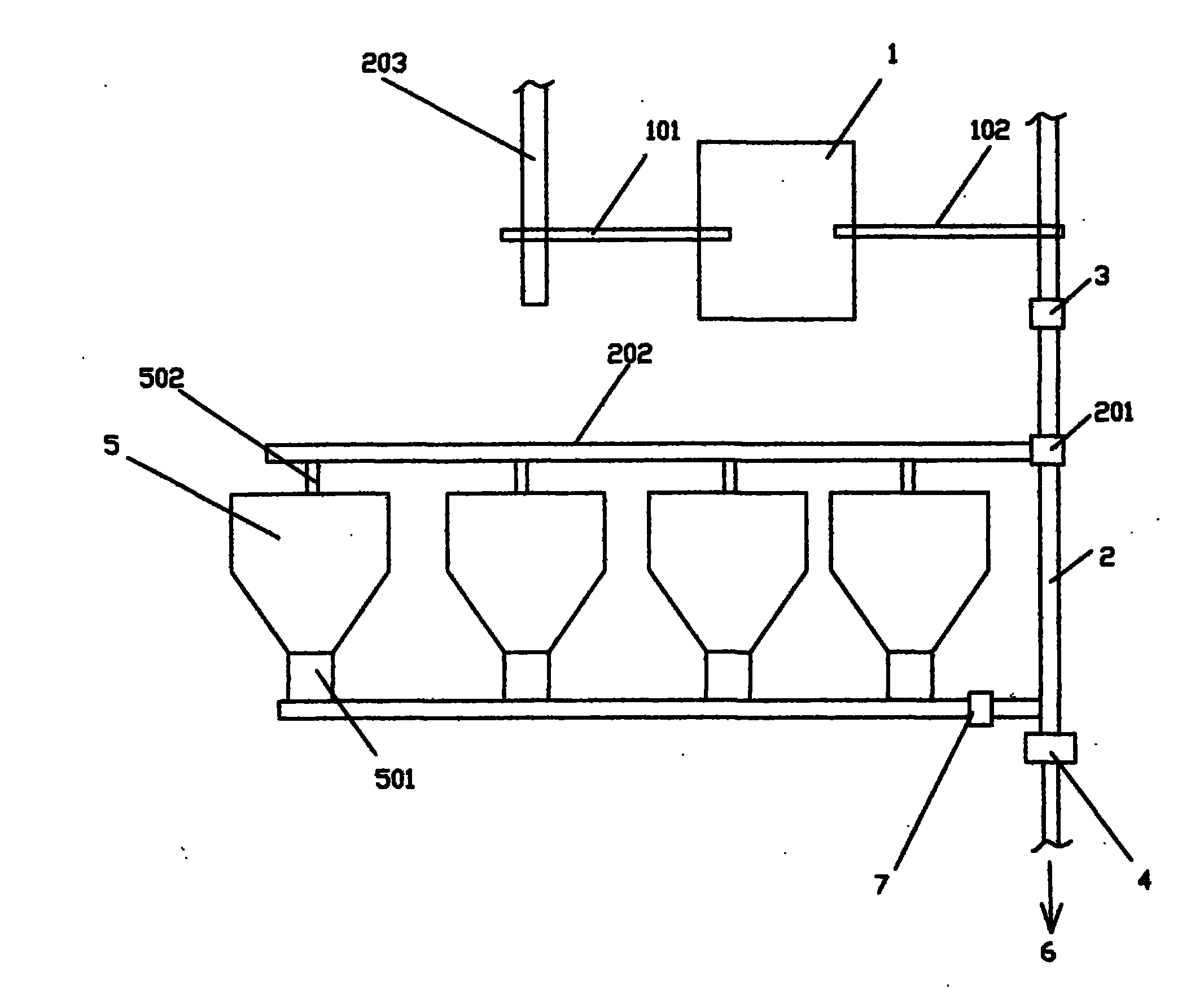

[0014] As shown in the figure, it includes a bottle blowing machine 1, a conveyor belt 2 and a labeling machine 4. It is characterized in that: the bottle blowing machine 1 blows out the bottle, and the bottle is transported by the conveyor belt 2 to the labeling machine 4 through the quality inspection 3 for labeling. After the label is sent out, the front and rear of the labeling machine 4 are equipped with detection devices. When it is detected that there are too many output bottles and cannot be processed in time, an electrical signal is automatically output to the automatic converter 201. The automatic converter 201 starts the second conveyor belt 202 to transport the bottles. to the bottle bin 5; when the detection device in front of the labeling machine 4 detects that the number of bottles sent is insufficient, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com