Thermal head control device

A control device and thermal head technology, applied in printing, printing plate preparation, etc., can solve the problems of lack of expressiveness of thin lines, dark color of printed matter, etc., and achieve the effects of shortening heating time, simple structure, and prolonging contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

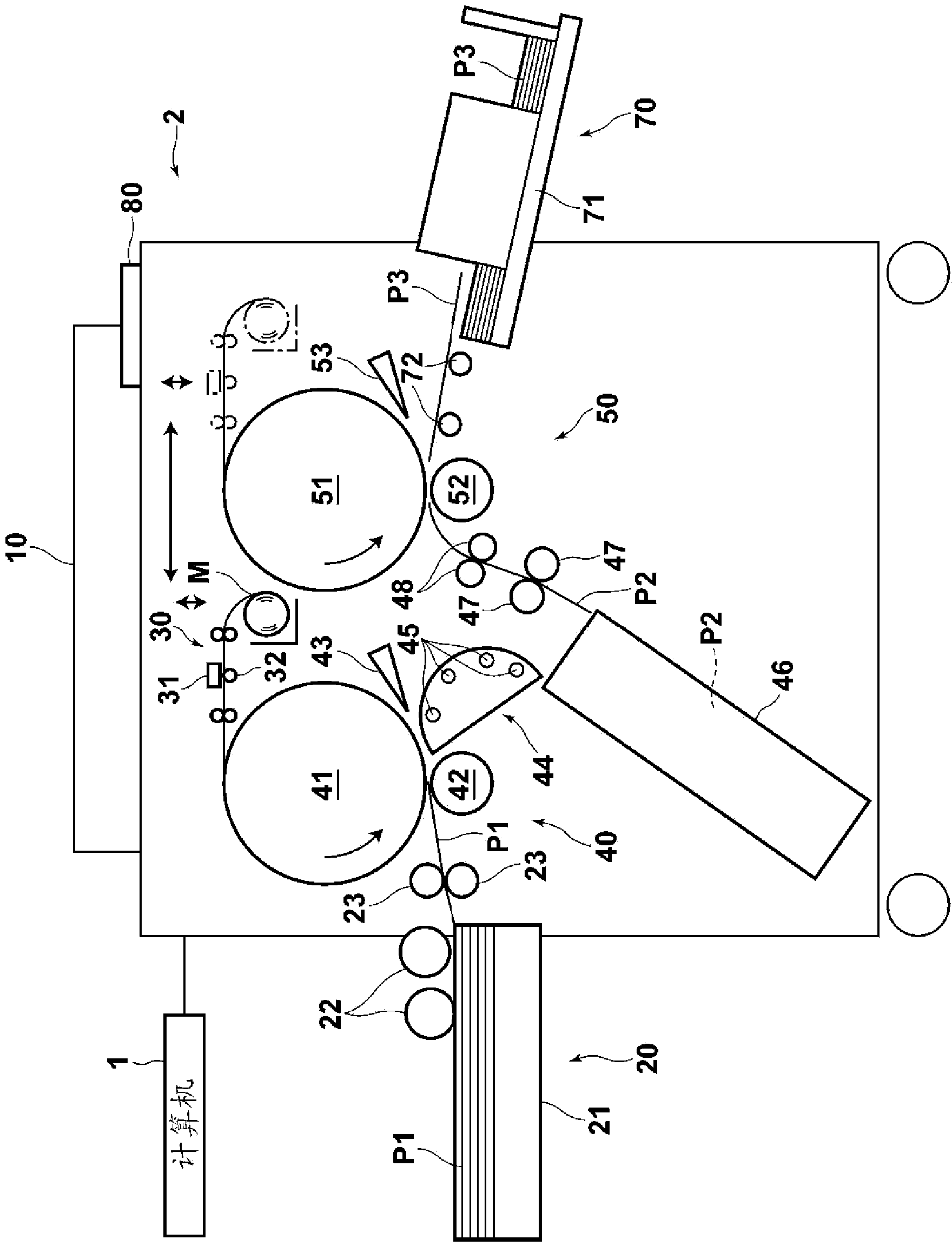

[0042] Next, a stencil printing system using an embodiment of the thermal head control device of the present invention will be described in detail with reference to the drawings. figure 1 This is a schematic diagram of the stencil printing system.

[0043] Such as figure 1 As shown, this stencil printing system includes a computer 1 and a stencil printing device 2. The computer 1 outputs image data for single-sided printing or double-sided printing. The stencil printing device 2 performs plate making based on the image data output from the computer 1. and stencil printing. This stencil printing system is characterized by a method of driving and controlling the thermal head in the stencil printing device 2 , and first, the overall structure of the stencil printing device 2 will be described.

[0044] Such as figure 1As shown, the stencil printing apparatus 2 includes: an image reading unit 10 that reads an image of an original document and outputs image data; image data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com