Liner motor arranging method for cordless elevator

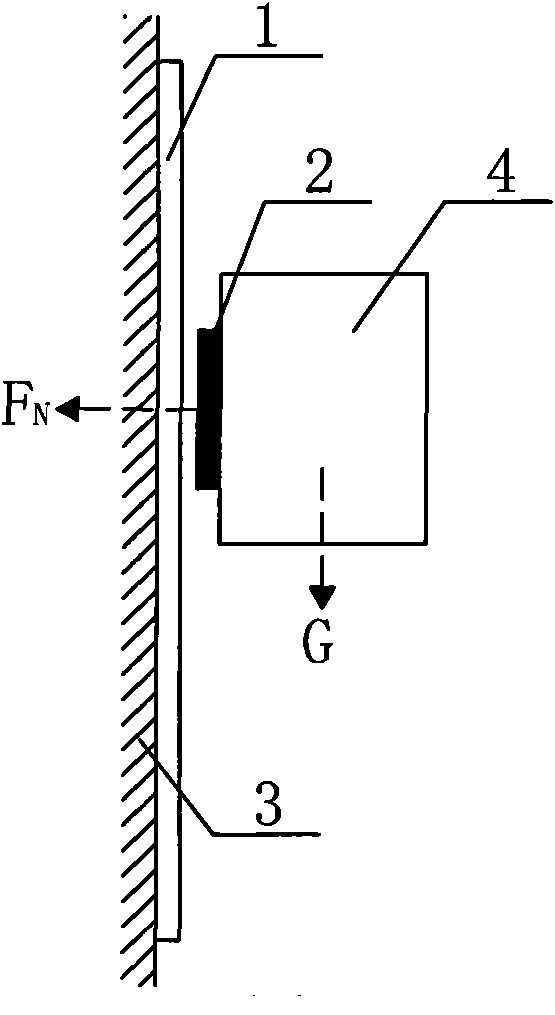

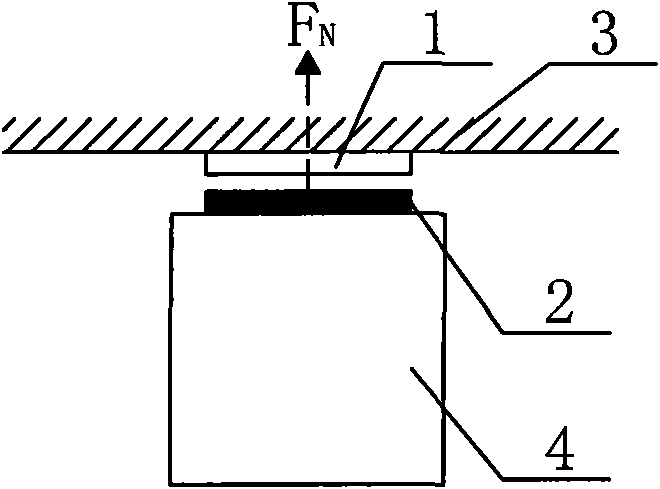

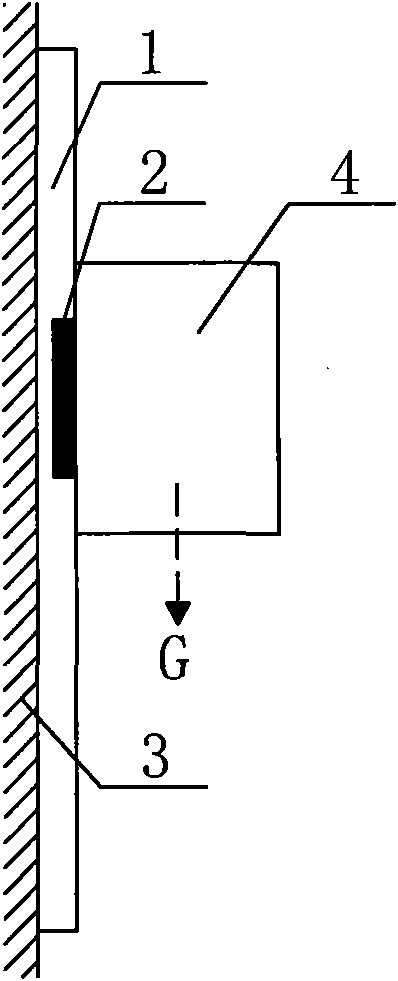

A technology of linear motors and layout methods, which is applied to elevators, transportation and packaging in buildings, can solve the problems of large normal force of permanent magnet linear motors, difficulties in positioning and operation, car roll and deflection, etc., and achieve The effect of compact motor structure, weight reduction, and reduced installation base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Such as Figure 5A As shown, a linear motor arrangement method for a cordless elevator includes two "U"-shaped linear motors and a car 4, a "U"-shaped beam 6 is installed on the installation foundation 3, and the motor stator part 1 is fixed on the "U" The two sides of the inner wall of the "shaped beam 6, and the motor mover part 2 form a bilateral structure "U" type linear motor. The motor mover part 2 is connected with the car 4 through a connecting mechanism 5, constituting the moving part of the cordless elevator. The openings of the two "U"-shaped linear motors are arranged face to face, that is, the angle between the axes of the two "U"-shaped linear motors is 0°, as Figure 6A shown.

[0025] Such as Figure 5B As shown, the two "U" linear motors are arranged back to back, and the other structures are the same Figure 5A . The included angle between the axes of two "U" type linear motors is a is 180°, such as Figure 6C shown.

[0026] Figure 5A and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com