Method for preparing anhydrous magnesium carbonate powder

A technology of anhydrous magnesium carbonate and powder, applied in the direction of magnesium carbonate, etc., can solve the problems that only hydrated alkali can be prepared, and anhydrous magnesium carbonate cannot be prepared, and achieve the effect of simple and feasible technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A flower-like anhydrous magnesium carbonate powder composed of a single phase is prepared. Its technological process comprises the following steps:

[0026] 1. Prepare 35ml of 1.0mol / L magnesium chloride solution, and prepare 35ml of urea solution according to the molar ratio of 1:4.

[0027] 2. Mix and stir the magnesium chloride solution and the urea solution evenly, and add 2.5 g of sodium citrate thereto.

[0028] 3. Add the reaction solution into a high-temperature and high-pressure reactor, and react at 120° C. for 24 hours.

[0029] 4. Take out the reaction kettle obtained from the reaction, and after cooling for 12 hours, wash the precipitate, filter it, and dry it.

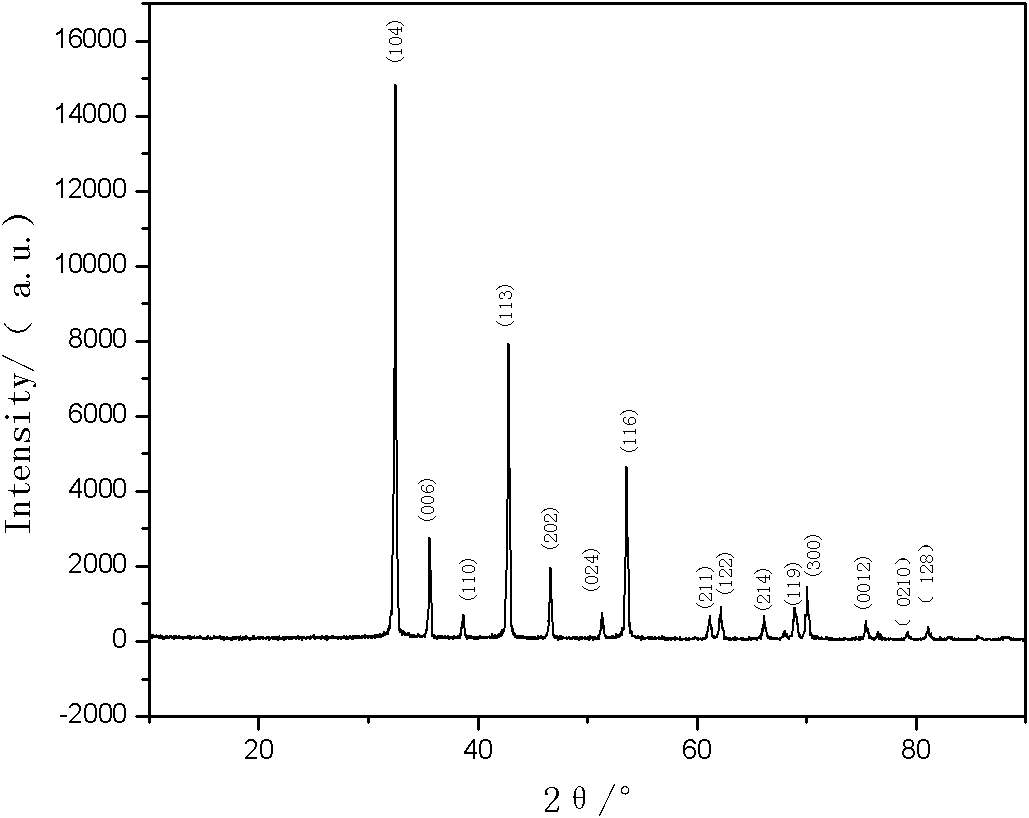

[0030] 5. The obtained sample is detected by an X-ray diffractometer and a scanning electron microscope, and the flower-shaped anhydrous magnesium carbonate powder composed of a single phase is obtained.

Embodiment 2

[0032] Spherical anhydrous magnesium carbonate powder composed of a single phase is prepared. Its technological process comprises the following steps:

[0033] 1. Prepare 35ml of 2.0mol / L magnesium chloride solution, and prepare 35ml of urea solution according to the molar ratio of 1:8.

[0034] 2. Mix and stir the magnesium chloride solution and the urea solution evenly, and add 3.7 g of sodium citrate thereto.

[0035] 3. Add the reaction solution into a high-temperature and high-pressure reactor, and react at 200°C for 24 hours.

[0036] 4. Take out the reaction kettle obtained from the reaction, and after cooling for 12 hours, wash the precipitate, filter it, and dry it.

[0037] 5. The obtained sample is detected by an X-ray diffractometer and a scanning electron microscope, and it is a spherical anhydrous magnesium carbonate powder composed of a single phase.

Embodiment 3

[0039] Anhydrous magnesium carbonate powder mixed with flower shape and spherical shape composed of single phase is prepared. Its technological process comprises the following steps:

[0040] 1. Prepare 35ml of 1.0mol / L magnesium chloride solution, and prepare 35ml of urea solution according to the molar ratio of 1:6.

[0041] 2. Mix and stir the magnesium chloride solution and the urea solution evenly, and add 4.5 g of sodium citrate thereto.

[0042] 3. Add the reaction solution into a high-temperature and high-pressure reactor, and react at 160° C. for 24 hours.

[0043] 4. Take out the reaction kettle obtained from the reaction, and after cooling for 12 hours, wash the precipitate, filter it, and dry it.

[0044] 5. The obtained sample is detected by X-ray diffractometer and scanning electron microscope, and the spherical anhydrous magnesium carbonate powder composed of a single phase is obtained

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com