Manufacturing method of baking paint of silver gray low-light writing board and color paste used thereby

A production method, silver-gray technology, applied in the direction of polyester paint, pigment slurry, coating, etc., can solve the problems of affecting students' vision, unsightly, short service life, etc., achieve good visual effects, solve dust pollution, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The color paste is made from the following raw materials in parts by weight:

[0028] 6 parts of polyester resin 50611, 10 parts of acrylic resin 9220, 15 parts of acrylic resin 2601, 5 parts of amino resin, 5 parts of wax powder, 20 parts of titanium dioxide, 0.1 part of carbon black, 0.1 part of iron yellow, 0.1 part of phthalocyanine blue 0.1 part of Phthalocyanine Green 5319, 0.1 part of Phthalocyanine Green 53400.1 part, 2 parts of talc, 8 parts of barium sulfate, 8 parts of calcium carbonate, 20 parts of matting agent, 0.5 part of dispersant 5027, 0.5 part of dispersant, 0.1 part of leveling agent, 3 parts of adhesion promoter, 1 part of anti-sedimentation agent, 20 parts of solvent;

Embodiment 2

[0030] The color paste is made from the following raw materials in parts by weight:

[0031] 8 parts of polyester resin 50611, 12 parts of acrylic resin 9220, 10 parts of acrylic resin 2601, 10 parts of amino resin, 6 parts of wax powder, 25 parts of titanium dioxide, 0.12 parts of carbon black, 0.2 parts of iron yellow, 0.2 parts of phthalocyanine blue 0.15 parts of phthalocyanine green 5319, 0.16 parts of phthalocyanine green 5340, 7 parts of talcum powder, 10 parts of barium sulfate, 8 parts of calcium carbonate, 10 parts of matting agent, 0.5 parts of dispersant 5027, 0.5 parts of dispersant 50400, 0.5 parts of leveling agent , 3 parts of adhesion promoter, 2 parts of anti-sedimentation agent, 20 parts of solvent;

Embodiment 3

[0033] The color paste is made from the following raw materials in parts by weight:

[0034] 10 parts of polyester resin 50611, 7 parts of acrylic resin 9220, 12 parts of acrylic resin 2601, 4 parts of amino resin, 7 parts of wax powder, 25 parts of titanium dioxide, 0.1 part of carbon black, 0.15 parts of iron yellow, 0.14 parts of phthalocyanine blue 0.16 parts of phthalocyanine green 5319, 0.17 parts of phthalocyanine green 5340, 12 parts of talcum powder, 8 parts of barium sulfate, 10 parts of calcium carbonate, 10 parts of matting agent, 0.5 parts of dispersant 5027, 0.6 part of dispersant 5040, and 0.1 part of leveling agent 3 parts, 3 parts of adhesion promoter, 1 part of anti-sedimentation agent, 20 parts of solvent;

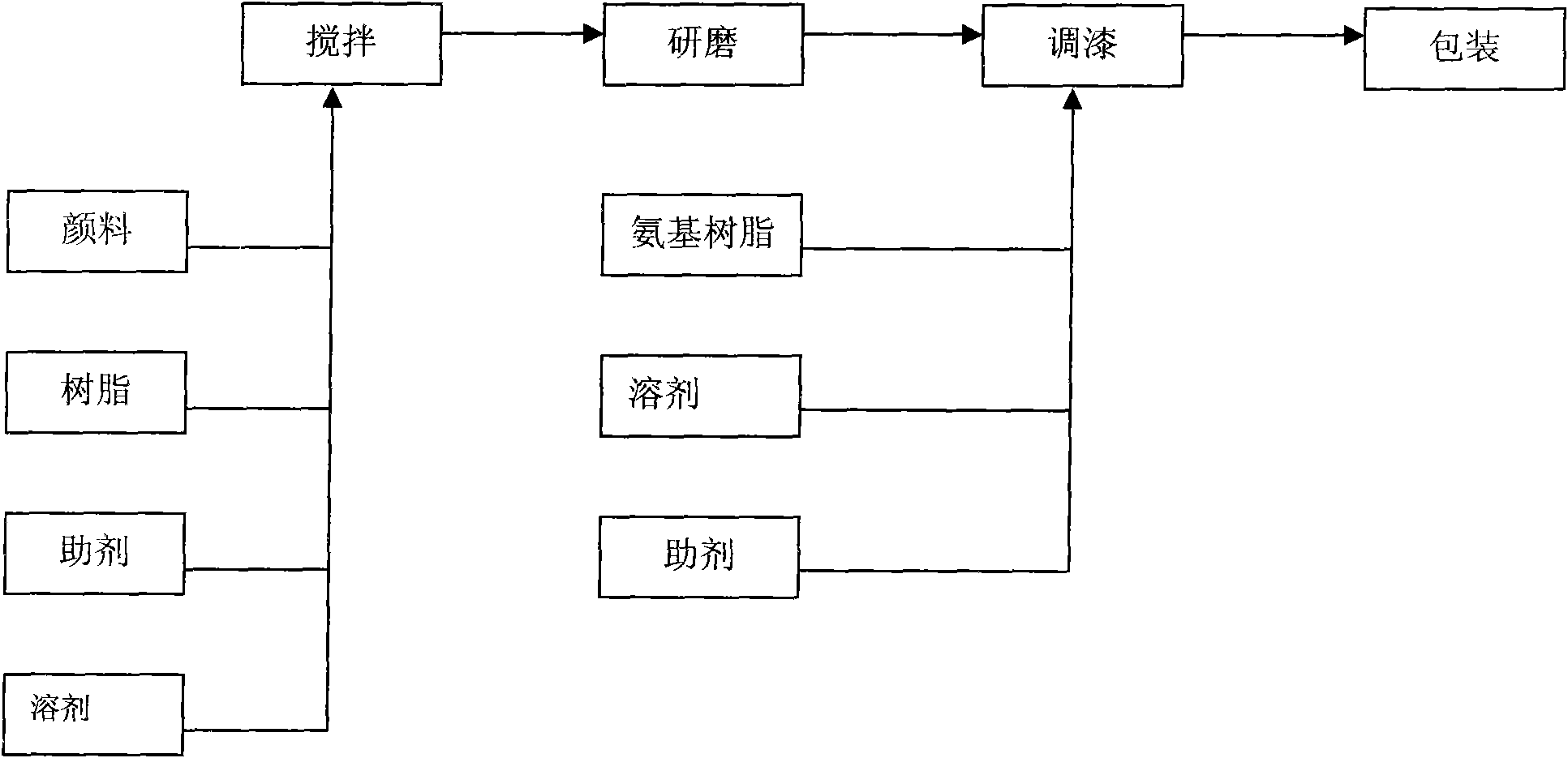

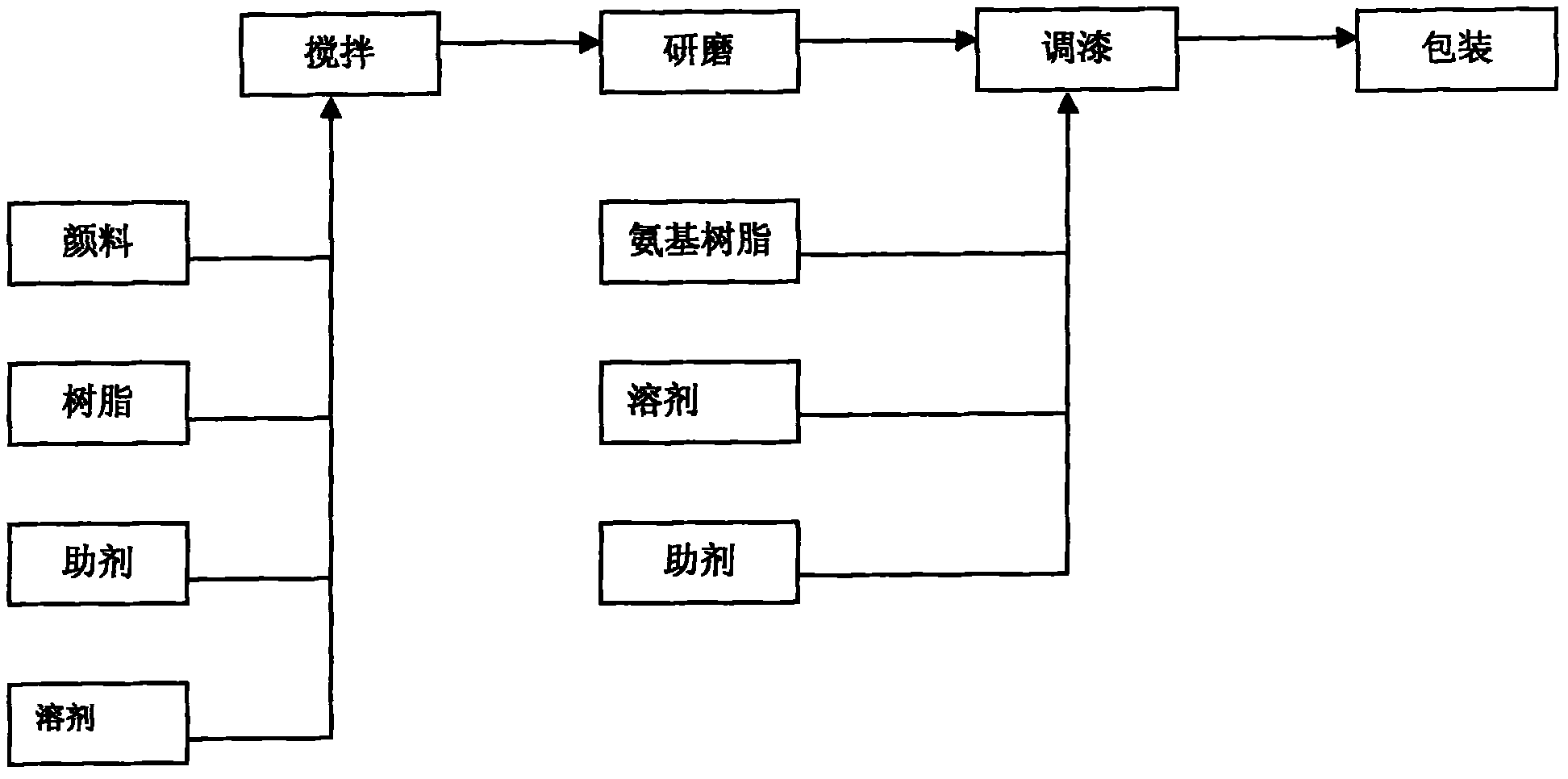

[0035] The preparation method of baking paint for silver gray blackboard maintenance of the present invention, it is to make according to following method:

[0036] 1) prepare color paste; (referring to embodiment 1-embodiment 3)

[0037] Its concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com