Color paste for environment-friendly blackboard coating and preparation method of special maintenance coating for environment-friendly blackboard

A production method and coating technology, applied in the direction of pigment slurry, polyurea/polyurethane coating, coating, etc., can solve the problems of polluting the environment, long maintenance period, affecting the eyesight of students, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The color paste is made from the following raw materials in parts by weight:

[0023] 15 parts of water-based polyurethane resin 2546, 10 parts of water-based polyurethane resin 2651, 7 parts of water-based polyurethane resin 2601, 1.2 parts of titanium dioxide, 1 part of carbon black, 5.7 parts of iron yellow, 1.5 parts of phthalocyanine blue, phthalocyanine green 5319 2.1 parts, phthalocyanine green 5340 2 parts, talc powder 12 parts, quartz powder 2 parts, barium sulfate 5 parts, calcium carbonate 5 parts, matting agent 2 parts, dispersant 5027 0.8 parts, dispersant 5040 0.7 parts, leveling agent 0.5 parts, 1 part of adhesion promoter, 1.5 parts of anti-settling agent, 1.2 parts of thickener, 1 part of antifungal agent, 2 parts of antifreeze, 11.8 parts of deionized water.

Embodiment 2

[0025] The color paste is made from the following raw materials in parts by weight:

[0026] 254625 parts of water-based polyurethane resin, 30 parts of water-based polyurethane resin 2651, 9 parts of water-based polyurethane resin 2601, 10 parts of titanium dioxide, 2 parts of carbon black, 12 parts of iron yellow, 8 parts of phthalocyanine blue, 5319 parts of phthalocyanine green 10 parts, phthalocyanine green 5340 10 parts, talcum powder 30 parts, quartz powder 20 parts, barium sulfate 11 parts, calcium carbonate 10 parts, matting agent 12 parts, dispersant 5027 1.5 parts, dispersant 5040 0.5 parts, leveling agent 1 2 parts, 2 parts of adhesion promoter, 8 parts of anti-settling agent, 2 parts of thickener, 2 parts of antifungal agent, 4 parts of antifreeze, 45 parts of deionized water.

Embodiment 3

[0028] The color paste is made from the following raw materials in parts by weight:

[0029] Water-based polyurethane resin 2546 50 parts, water-based polyurethane resin 2651 45 parts, water-based polyurethane resin 2601 22 parts, titanium dioxide 10 parts, carbon black 2.5 parts, iron yellow 10 parts, phthalocyanine blue 10 parts, phthalocyanine green 15 parts of 5319, 2 parts of phthalocyanine green 5340, 16 parts of talcum powder, 4 parts of quartz powder, 8 parts of barium sulfate, 5 parts of calcium carbonate, 7 parts of matting agent, 5 parts of dispersant 5027, 5 parts of dispersant 5040, leveling agent 2 parts, 3 parts of adhesion promoter, 5 parts of anti-settling agent, 1.5 parts of thickener, 1.5 parts of antifungal agent, 3 parts of antifreeze, 20 parts of deionized water.

[0030] The preparation method of green blackboard maintenance special coating of the present invention, it is to make according to following method:

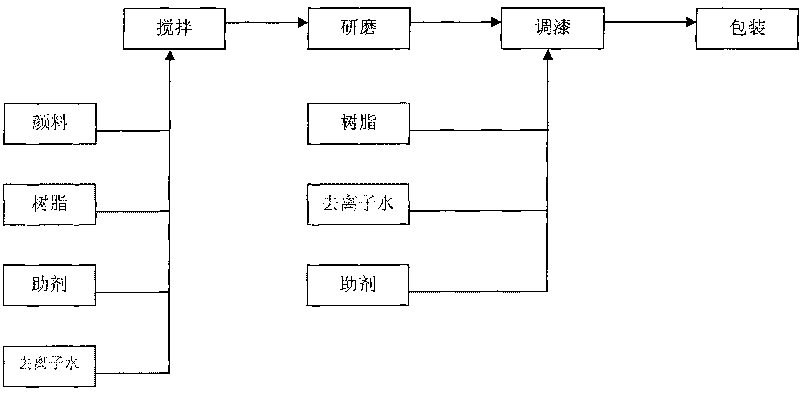

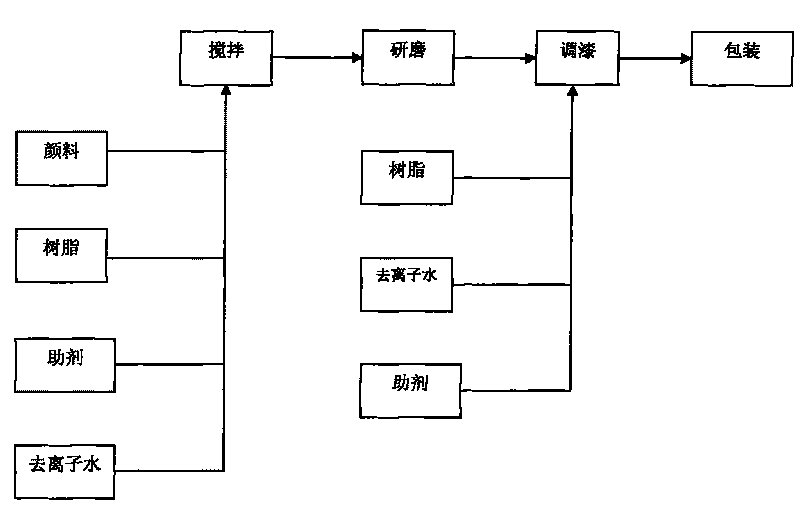

[0031] 1) prepare color paste; (referring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com