Roof gutter system capable of generating slope

A gutter and roof technology, applied in the direction of roof, roof covering, roof insulation materials, etc., can solve the problems of difficult maintenance and easy accumulation of water on the surface of the gutter, so as to reduce project cost, save steel consumption, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

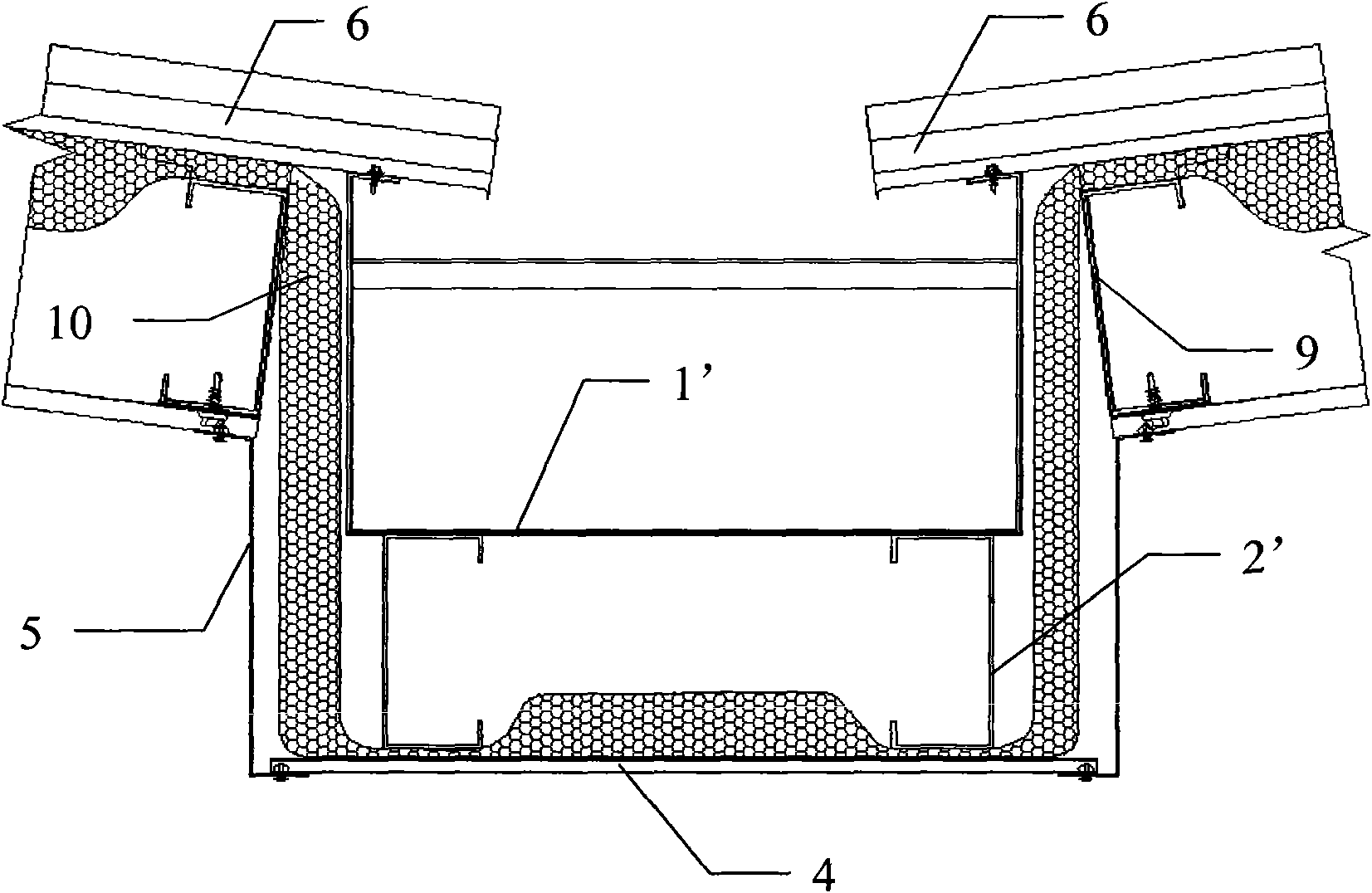

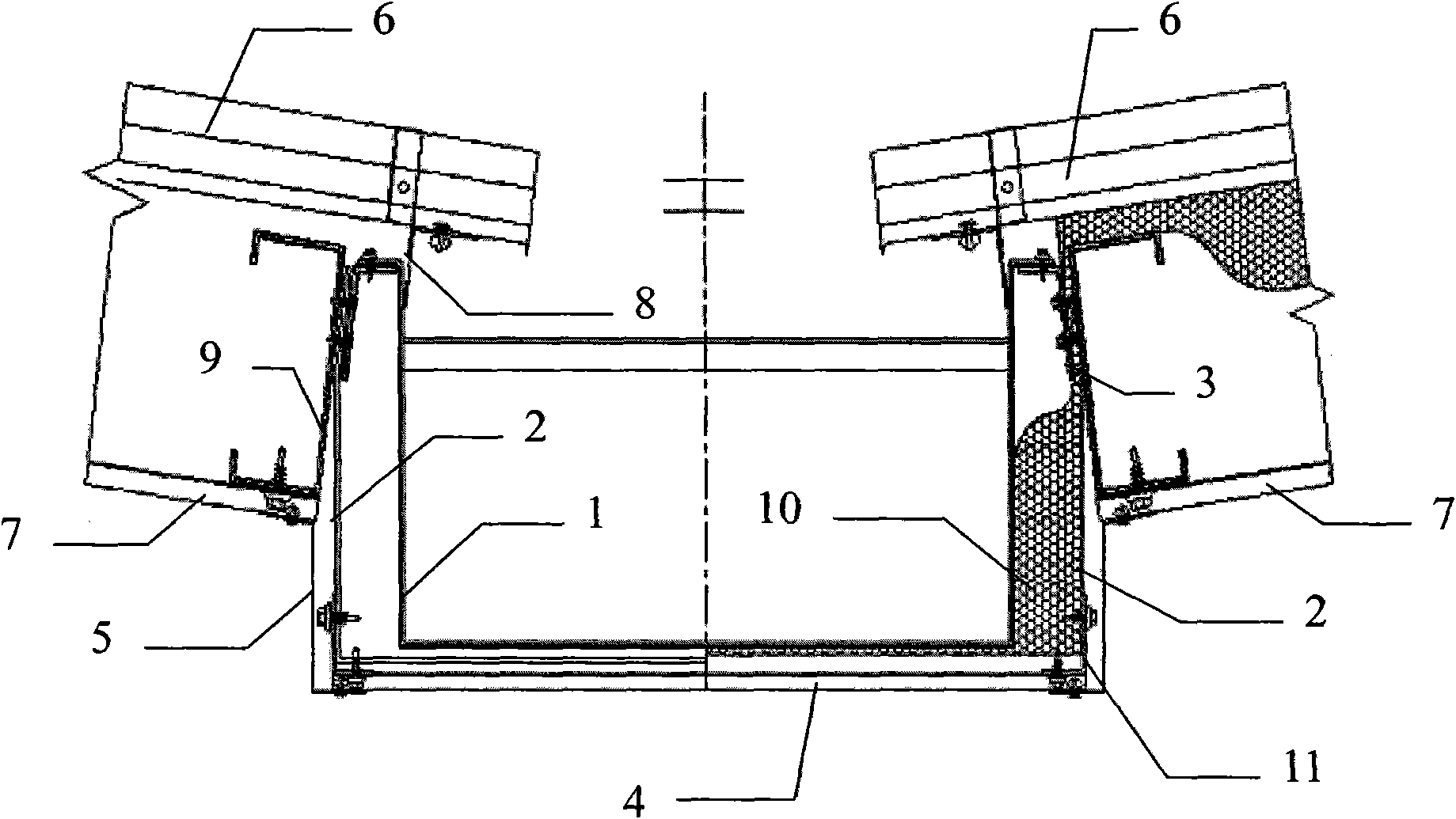

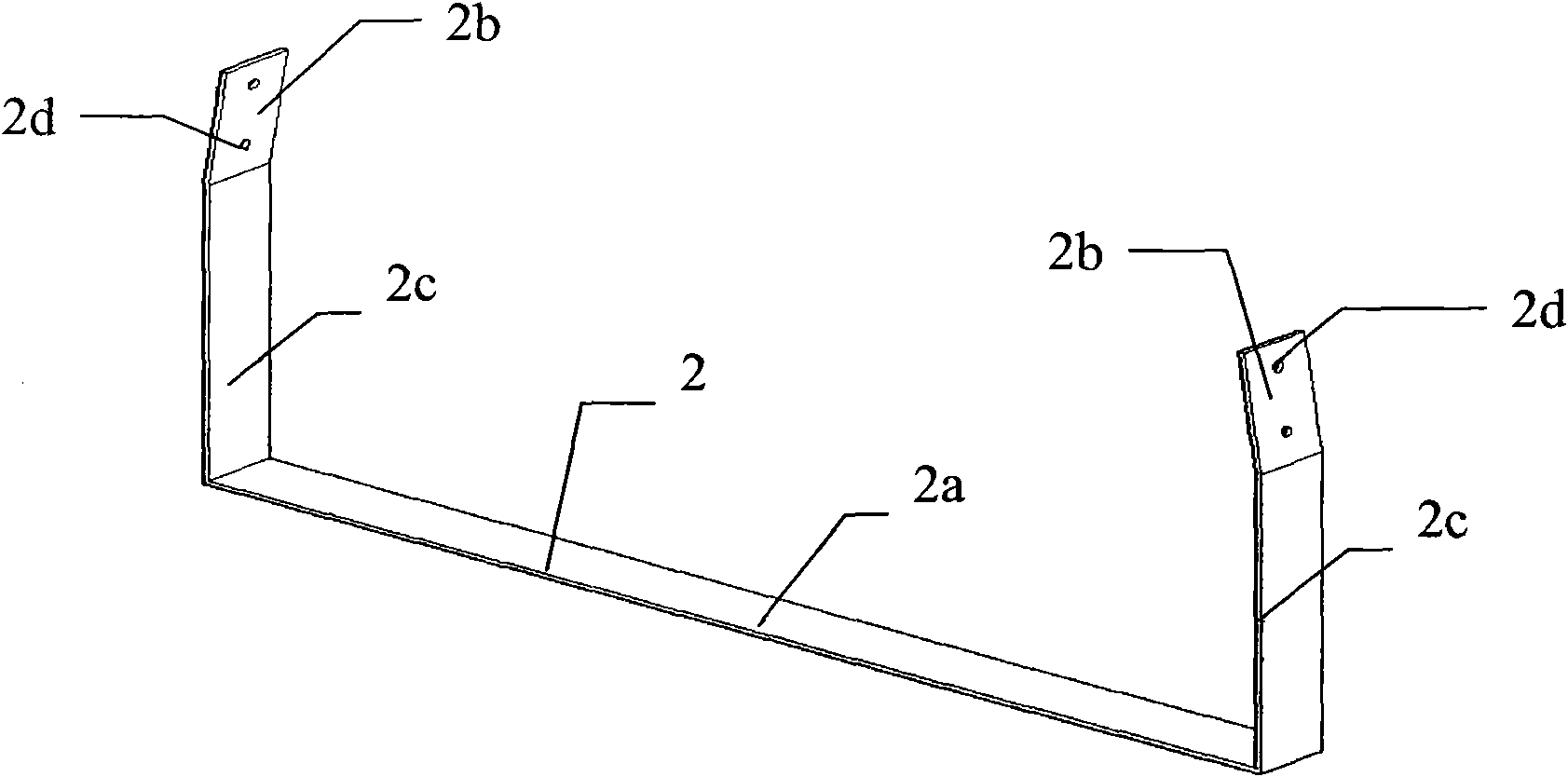

[0026]A roof gutter system capable of generating slopes, comprising: gutter 1; gutter conversion frame 2; gutter bracket 3; gutter ceiling plate 4; edge wrapping piece 5; metal roof panel 6; roof ceiling plate 7; Fascia board 8; roof purlin 9; insulation layer 10; full-length angle steel 11, of which gutter 1 is made by bending 2.5mm thick steel plate. The height of 1b is 300mm, the width of the bottom 1a is 450mm, the width of the upper flange 1c on both sides is 40mm, the thickness of the steel belt of the gutter conversion frame 2 is 3.0mm, the width of the 7 steel belt is 40mm, and the bottom surface of the conversion frame 2a The width is 500mm, the height of the top slope 2b on both sides is 60mm, the height of the side 2c is 240mm, and two Φ6.5 round holes are opened on the upper ends of the two sides 2b; the angle between 2c and 2b is 175; the strip steel of the gutter bracket 3 The thickness is 3.0mm, the width of the strip steel is 40mm, the width of the top support ...

Embodiment 2

[0035] Such as Figure 10 As shown, a roof gutter system that can generate slopes includes: gutter 1; gutter conversion frame 2, gutter bracket 3, metal roof panel 6; fascia board 8; roof purlin 9; insulation layer 10; Among them, the gutter 1 is made of 3.0mm thick galvanized steel sheet by bending. According to the design drainage volume of the roof and the number of rainwater outlets, the height of the side 1b of the gutter 1 is 350mm, and the width of the bottom 1a is 500mm. The width of the hem 1c is 35mm. The strip steel thickness of the gutter conversion frame 2 is 2.0mm, the strip steel width is 40mm, the width of the bottom surface 2a of the conversion frame is 560mm, the height of the top slope 2b on both sides is 60mm, the height of the side 2c is 290mm, and the upper ends of the two sides 2b Open 2 Φ6.5 round holes; the angle between 2c and 2b is 175

[0036] The strip steel thickness of gutter bracket 3 is 3.0mm, the width of strip steel is 50mm, the width of gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com